[0003] The belt-type sludge deep

dewatering machine of the prior art has the following problems: 1. In order to properly treat the sludge, the traditional method of separating the

solid-liquid two-phase using a plate-and-frame

filter press is generally used for sludge

dehydration treatment, but Such a treatment method cannot be deeply dewatered, and the

water content in the output sludge is relatively high. In order to improve this problem, the existing belt

sludge dewatering machine is used, and its

dehydration method is mixed reaction of sludge and flocculant, and then After gravity

dehydration, wedge pressure dehydration, low pressure dehydration,

medium pressure dehydration and

high pressure dehydration, the sludge

moisture is gradually reduced, and finally discharged as

solid matter. Although the problem of

high water content in the sludge is improved, the dehydration process is complicated and cumbersome. The machine occupies a large area, wastes manpower and

material resources, and increases the cost of use; 2. The dehumidification method of the existing belt sludge dehydrator mostly adopts dehumidification + condensation, which is an

open structure. In order to avoid

organic matter in the dehydration process The

waste gas produced by volatilization is discharged into the air, causing

pollution to the environment. The existing belt sludge dehydrator needs to install a matching complex deodorization device in the dehydration device. Due to its own structural factors, the deodorization device requires operators to It is cleaned and inspected regularly, which increases the work intensity of the operator

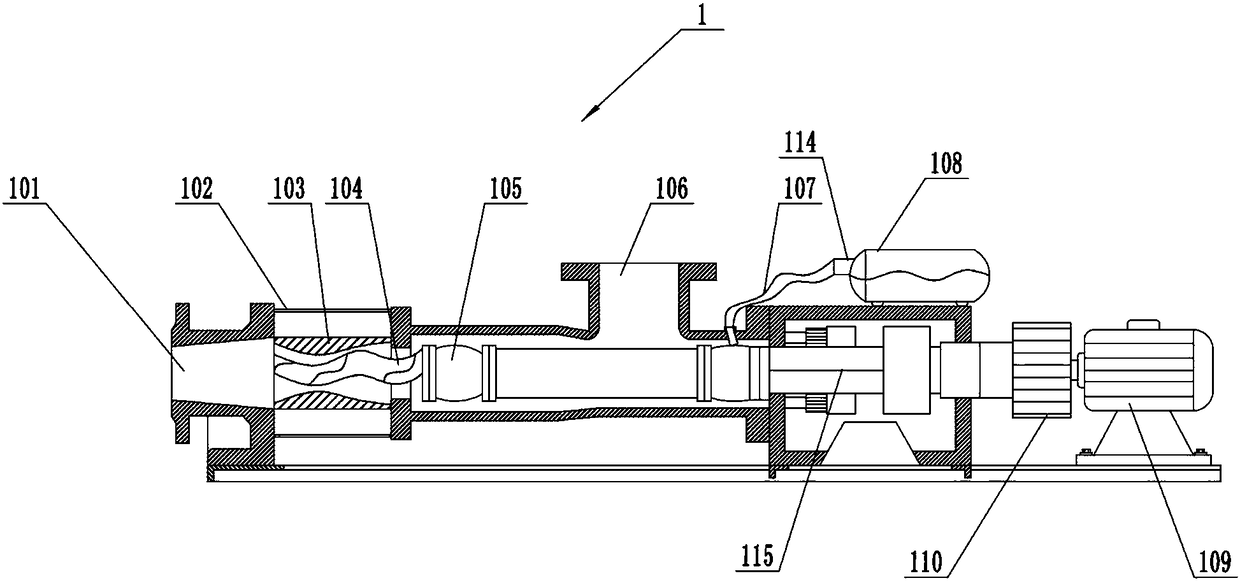

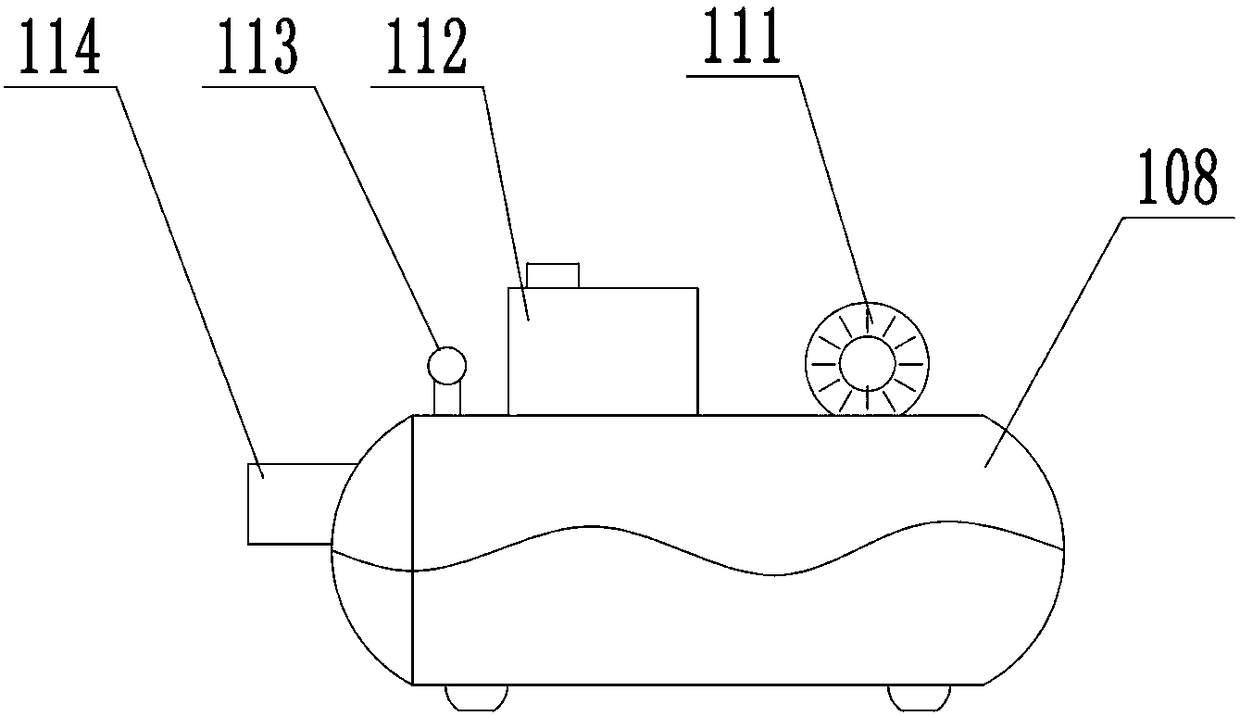

[0004] The sludge delivery pump of the prior art has the following problems: 1. There are some defects in the current sludge delivery pump. The cleaning of the delivery pump is an important item of

machine maintenance. The sludge will remain when the sludge is transported. If the sludge is not cleaned properly In time, when the equipment starts up again, the load is too large, which will have a bad influence on the idlers, bearings and vibration motors, and even burn the motors

[0007] There are following problems in the drying machine sludge

cutting device of the prior art: 1. With the quickening pace of urban development, more and more sludge is produced in the urban

sewage discharge pipe network, and the types of impurities in the sludge are also increasing. More and more, when the slitting device cuts the sludge, the sludge will contain hair, fibers and other sundries, some will be mixed in the sludge and go out from the inside of the slitting device, and some will be stuck in the slitting device. In the

sieve hole, with the increase in the number of strip

cutting devices, the

sieve hole of the slitting device will gradually be blocked, because there is no relevant equipment for shearing and crushing, which will cause damage to the sludge slitting device in severe cases; 2. The cutting function of the cutting device of most belt dryers has been gradually perfected, but the follow-up cleaning work of the cutting device is still not highly valued by the manufacturer, and most of the existing sludge cutting devices still use Manual cleaning, the manual cleaning machine cannot guarantee a full range of cleaning of the machine, the cleaning effect is poor, and the labor intensity is high, which increases the work intensity of the staff and is time-consuming and laborious

[0008] The following problems exist in the sludge drying of the prior art: the sludge drying treatment of the prior art mostly adopts thermal drying treatment, adopts

paddle type drying machines, vertical multi-disc drying machines, rotary disc drying machines and Low-temperature belt dryers are used to dry sludge. Low-temperature belt dryers have obvious advantages in terms of

mechanical wear,

environmental protection,

odor, and

operation safety. Therefore, low-temperature belt dryers are often used. For the drying treatment of sludge, the low-temperature belt dryer uses a dehumidification

heat pump to dry the sludge by hot air circulation, condensation, dehumidification and drying technology, but the existing low-temperature belt dryer lacks sludge raw materials The uniform stirring function, and the hot air passing through the dehumidification heat pump is not dry enough, which will affect the result of sludge drying treatment

[0009] The sludge mesh belt conveying device of the low-temperature belt dryer in the prior art has the following problems: the mesh

belt conveyor of the existing low-temperature belt dryer generally has no side, and when the dryer is used to dry the sludge When the sludge falls on the

conveyor belt by its own gravity, some sludge will inevitably splash out of the

conveyor belt. If things go on like this, a large amount of sludge will accumulate at the bottom of the dryer box, and the sludge at the bottom of the box will It will be extremely inconvenient to

clean up, so it is necessary to improve the structure of the mesh belt conveying device of the existing low temperature belt dryer

Login to View More

Login to View More  Login to View More

Login to View More