Silicon-doped medical pure titanium surface porous bioactive coating and preparation method thereof

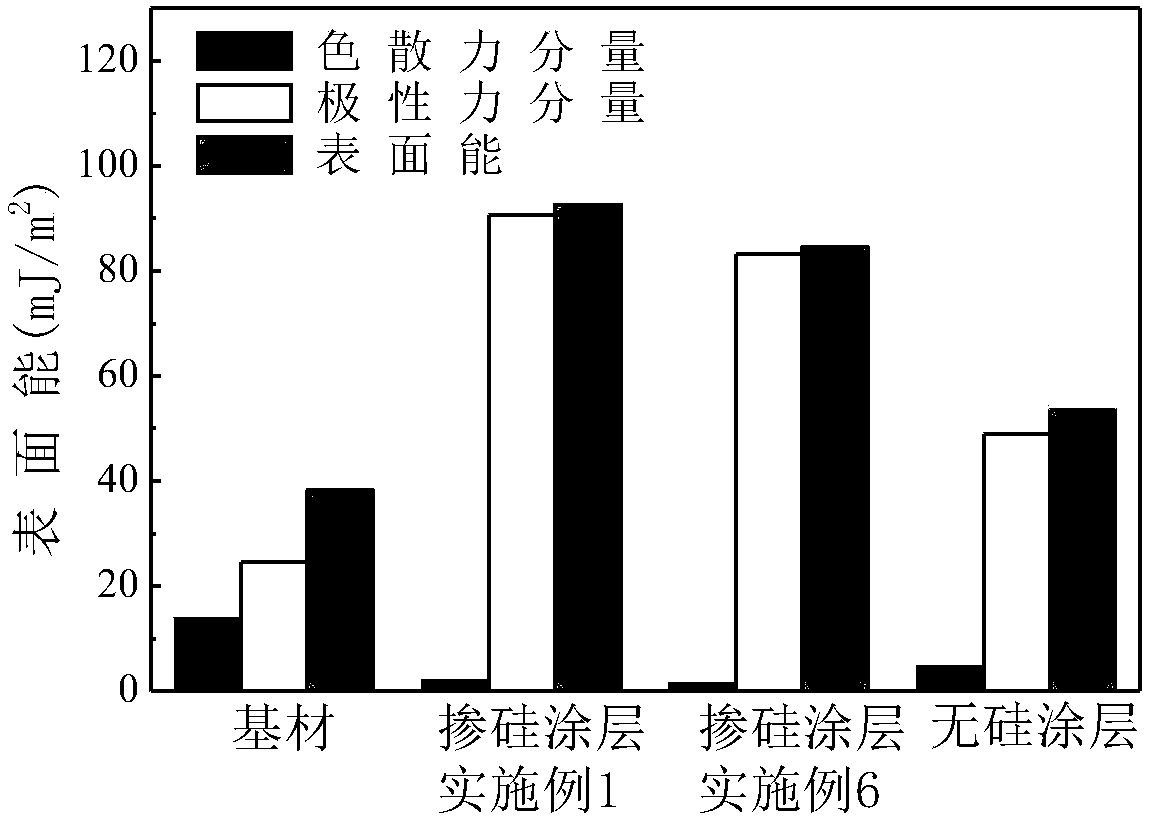

A bioactive, surface-porous technology, applied in the field of biomedical materials, can solve the problems of unsatisfactory biological activity and insufficient strength, and achieve the effects of inducing adhesion and proliferation, improving hydrophilic properties, and enhancing surface energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032](1) Put pure titanium (TA2) in B C Equal-channel angular extrusion deformation was carried out in the same way, and the extrusion temperature was 450°C. B here C The method refers to the extrusion method in which the workpiece is rotated 90° in the same direction after each extrusion, and then undergoes the next extrusion. After a total of four extrusion passes, the ultra-fine-grained pure titanium material (ECAP TA2) is obtained.

[0033] (2) First, the ultra-fine-grained pure titanium material is wire-cut into a round cake shape with a thickness of 2mm, and then polished with 150#, 200#, 500#, 800#, 1000#, 2000#, 5000# sandpaper step by step to remove the test pieces. The oxide layer on the surface of the sample was cleaned until there was no obvious scratch, and the polished ultra-fine-grained pure titanium material was ultrasonically cleaned in acetone, alcohol, and deionized water for 15 minutes, and dried for later use.

[0034] (3) Pour the weighed analytically ...

Embodiment 2

[0037] (1) Put pure titanium (TA2) in B C Equal-channel angular extrusion deformation was carried out in the same way, and the extrusion temperature was 450°C. B here C The method refers to the extrusion method in which the workpiece is rotated 90° in the same direction after each extrusion, and then undergoes the next extrusion. After a total of four extrusion passes, the ultra-fine-grained pure titanium material (ECAP TA2) is obtained.

[0038] (2) First, the ultra-fine-grained pure titanium material is wire-cut into a round cake shape with a thickness of 2mm, and then polished with 150#, 200#, 500#, 800#, 1000#, 2000#, 5000# sandpaper step by step to remove the test pieces. The oxide layer on the surface of the sample was cleaned until there was no obvious scratch, and the polished ultra-fine-grained pure titanium material was ultrasonically cleaned in acetone, alcohol, and deionized water for 15 minutes, and dried for later use.

[0039] (3) Pour the weighed analytically...

Embodiment 3

[0042] (1) Put pure titanium (TA2) in B C Equal-channel angular extrusion deformation was carried out in the same way, and the extrusion temperature was 450°C. B here C The method refers to the extrusion method in which the workpiece is rotated 90° in the same direction after each extrusion, and then undergoes the next extrusion. After a total of four extrusion passes, the ultra-fine-grained pure titanium material (ECAP TA2) is obtained.

[0043] (2) First, the ultra-fine-grained pure titanium material is wire-cut into a round cake shape with a thickness of 2mm, and then polished with 150#, 200#, 500#, 800#, 1000#, 2000#, 5000# sandpaper step by step to remove the test pieces. The oxide layer on the surface of the sample was cleaned until there was no obvious scratch, and the polished ultra-fine-grained pure titanium material was ultrasonically cleaned in acetone, alcohol, and deionized water for 15 minutes, and dried for later use.

[0044] (3) Pour the weighed analytically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com