Efficient large-size monocrystal diamond growth method and device

A single crystal diamond and growth method technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of diamond introducing impurity nitrogen, lattice dislocation, high defect density, etc., and achieve accelerated and rapid growth with low energy , the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

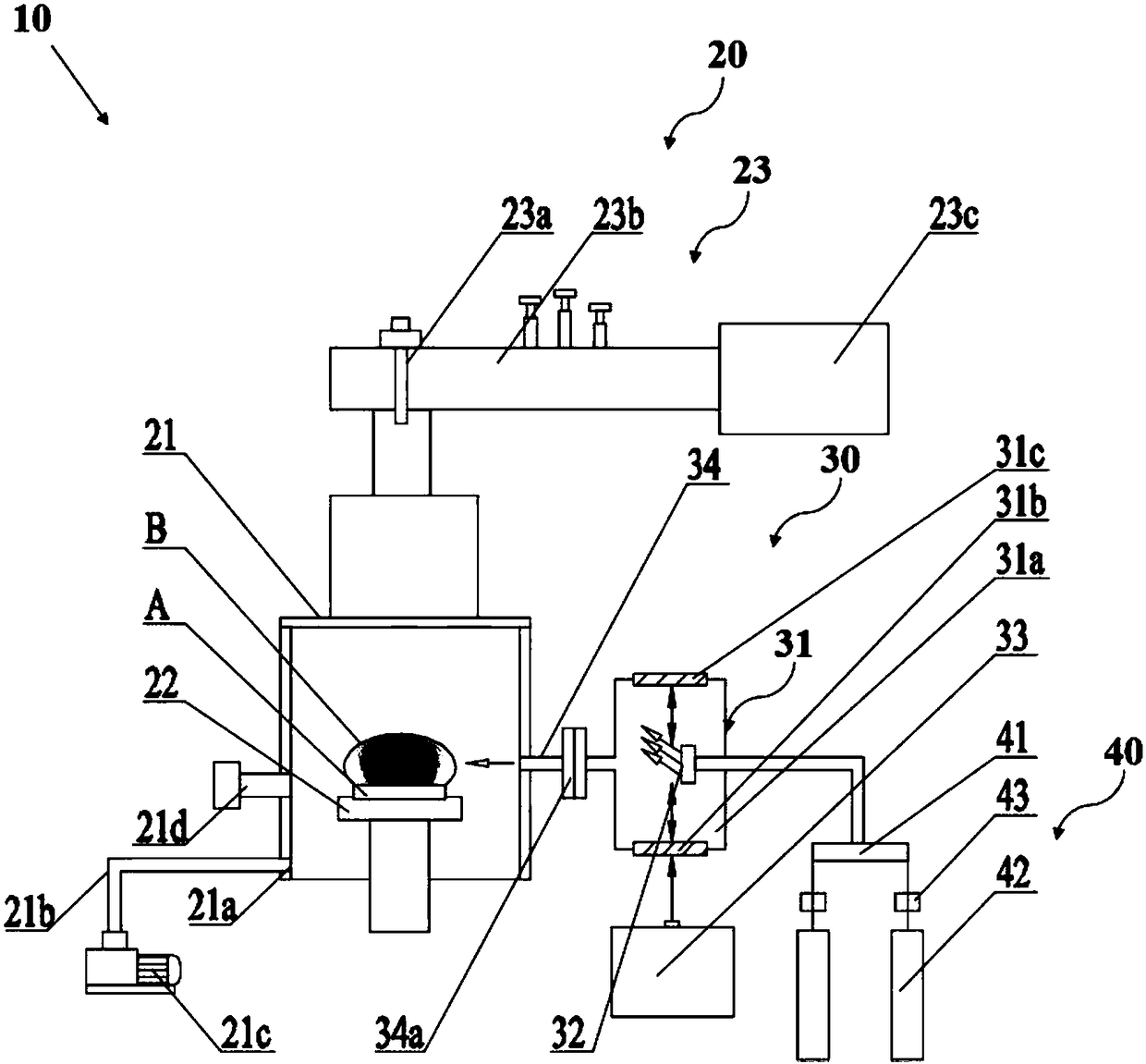

[0038] Such as figure 1 As shown, the high-efficiency large-size single crystal diamond growth device 10 includes a vapor deposition part 20 , a laser dissociation part 30 , an electric field application part (not shown in the figure), and a gas supply part 40 .

[0039] The vapor deposition unit 20 is an MPCVD device, which includes a microwave resonant cavity 21 , a substrate stage 22 , and a microwave generator 23 .

[0040] The microwave resonant cavity 21 is used for diamond epitaxial growth. In this embodiment, the inner diameter of the microwave resonant cavity 21 is 360 mm. The lower part of the side of the microwave resonator 21 is provided with an exhaust port 21a, and the exhaust port 21a is connected to the vacuum pump 21c through the bellows 21b; before the gas is introduced into the microwave resonator 21, the pressure in the cavity can be controlled at 0.1Pa by the vacuum pump 21c or higher; a thermocouple sensor 21d is installed on the side of the microwave ca...

Embodiment 2

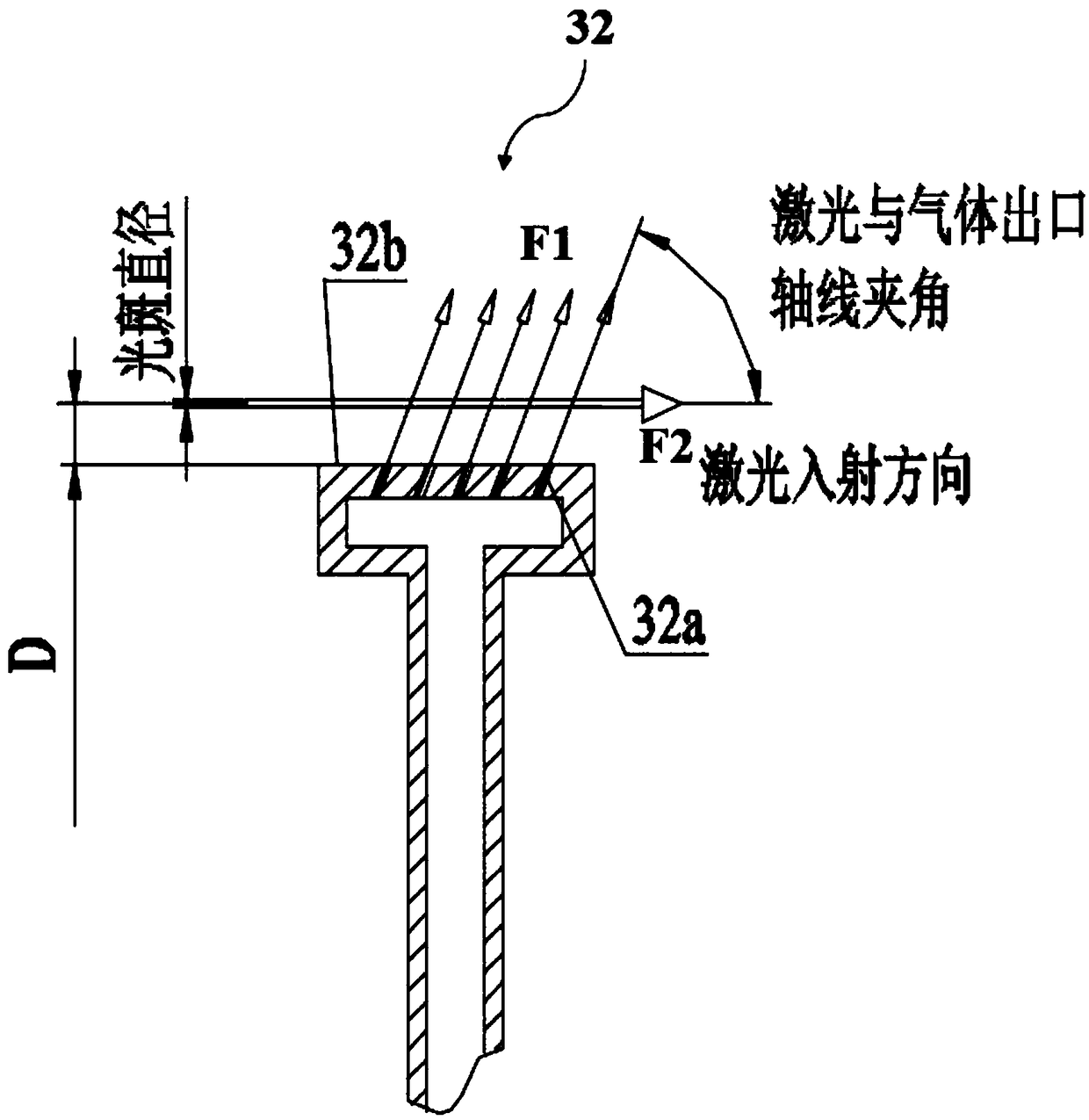

[0055] The method of combining laser dissociation chamber 31 with microwave plasma chemical vapor deposition is used to grow single crystal diamond. Before deposition, the growth surface of the seed crystal is firstly polished, pickled and ultrasonically washed in deionized water, dried with hot air and placed on the substrate stage 22. Utilize the vacuum pump 21c to evacuate the air pressure in the chamber to 0.1Pa, and feed 100 sccm of H 2 The entire microwave resonant cavity 21 is replaced. Turn on the microwave generator 23, set the microwave power and air pressure at 8kW and 18kPa respectively, and control the deposition temperature at 980°C. 4 :H 2 =1.5% (V / V), the total gas flow is controlled at 400 sccm. Turn on the laser 33, select a femtosecond laser with a center wavelength of 1061nm, a pulse width of 80fs, and a laser incident peak power of 2×10 12 W / cm 2 . The rear mirror 31c on the laser dissociation cavity 31 has a reflectivity of 100% to the incident ligh...

Embodiment 3

[0057] The method of combining laser dissociation chamber 31 with microwave plasma chemical vapor deposition is used to grow single crystal diamond. Before deposition, the growth surface of the seed crystal is firstly polished, pickled and ultrasonically washed in deionized water, dried with hot air and placed on the substrate stage 22. Utilize the vacuum pump 21c to evacuate the air pressure in the chamber to 0.1Pa, and feed 100 sccm of H 2 The entire microwave resonant cavity 21 is replaced. Turn on the microwave generator 23, set the microwave power and air pressure at 8kW and 18kPa respectively, and control the deposition temperature at 980°C. 4 :H 2 =2% (V / V), the total gas flow is controlled at 400 sccm. Turn on the laser 33, select the femtosecond laser with a center wavelength of 1061nm, a pulse width of 80fs, and a laser incident peak power of 3×10 12 W / cm 2 . The rear mirror on the laser dissociation chamber 31 has a reflectivity of 100% to the incident light, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com