Method for manufacturing intelligent transparent and conductive fabric based on composite modification of nanoparticles and nanowires

A technology of transparent conduction and composite modification, which is applied in the direction of textiles and papermaking, light-resistant fibers, fiber treatment, etc., can solve the problems of rare applications, and achieve the effect of improving conductivity, conductivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

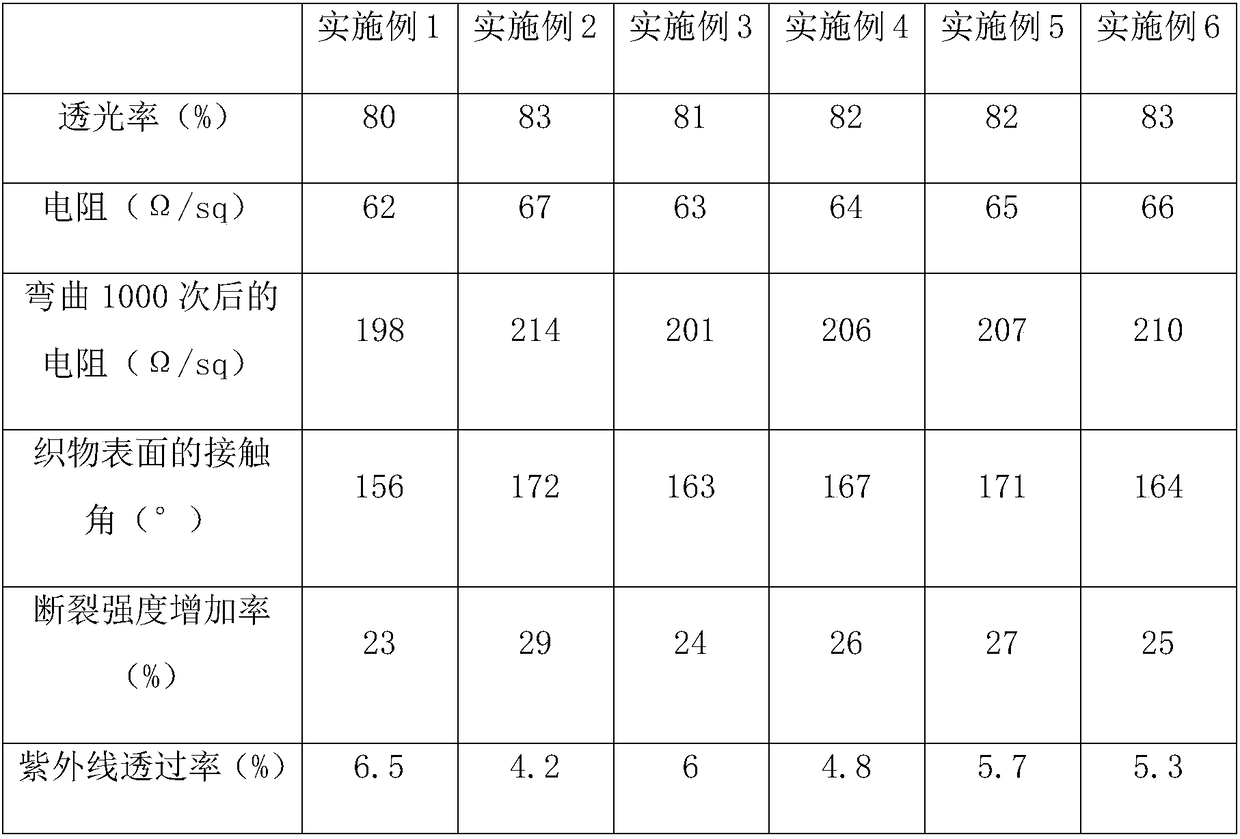

Examples

Embodiment 1

[0025] (1) According to the mass ratio of ethylene glycol, high molecular weight polyvinylpyrrolidone, copper chloride and silver nitrate as 80:0.2:1:0.1, add the high-purity ethylene glycol with a molecular weight of 130 In the high-molecular-weight polyvinylpyrrolidone, stir vigorously at a rate of 5000r / min until the polyvinylpyrrolidone is completely dissolved, then add copper chloride, seal and heat the reaction at 150°C for 30min, then add 5wt% silver nitrate solution to Stir vigorously at a rate of 5000r / min in the dark, heat in an oven at 130°C for 6h, and wash to obtain a mixed solution of silver nanowires and silver nanoparticles, wherein the diameter of silver nanowires is 200nm and the particle size of silver nanoparticles is 150nm .

[0026] (2) According to the mass ratio of silver nanowires, silver nanoparticles, conductive polymers, silicon nanowires and graphene of 10:0.5:20:5:0.5, the mixed solution of silver nanowires and silver nanoparticles was added to po...

Embodiment 2

[0030] (1) According to the mass ratio of ethylene glycol, high molecular weight polyvinylpyrrolidone, copper chloride and silver nitrate as 100:0.25:1.5:10, add the high-purity ethylene glycol with a molecular weight of 130 Wan's high molecular weight polyvinylpyrrolidone, stir vigorously at a rate of 8000r / min until the polyvinylpyrrolidone is completely dissolved, then add copper chloride, seal and heat the reaction at 160°C for 45min, then add 10wt% silver nitrate solution to Stir vigorously at a speed of 8000r / min in the dark, heat in an oven at 140°C for 10h, and wash to obtain a mixed solution of silver nanowires and silver nanoparticles, wherein the diameter of silver nanowires is 500nm and the particle size of silver nanoparticles is 350nm .

[0031] (2) According to the mass ratio of silver nanowires, silver nanoparticles, conductive polymers, silicon nanowires and graphene as 20:5:30:10:2, add the mixed solution of silver nanowires and silver nanoparticles to polypy...

Embodiment 3

[0035] (1) According to the mass ratio of ethylene glycol, high molecular weight polyvinylpyrrolidone, copper chloride and silver nitrate as 90:0.23:1.2:1, add the high-purity ethylene glycol with a molecular weight of 130 Wan's high molecular weight polyvinylpyrrolidone, stirred vigorously at a rate of 6000r / min until the polyvinylpyrrolidone was completely dissolved, then added copper chloride, sealed and heated at 155°C for 35min, then added 6wt% silver nitrate solution to Stir vigorously at a rate of 7000r / min in the dark, heat in an oven at 135°C for 7h, and wash to obtain a mixed solution of silver nanowires and silver nanoparticles, wherein the diameter of the silver nanowires is 300nm and the particle size of the silver nanoparticles is 200nm .

[0036] (2) According to the mass ratio of silver nanowires, silver nanoparticles, conductive polymers, silicon nanowires and graphene of 15:1:25:6:1, the mixed solution of silver nanowires and silver nanoparticles was added to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com