Heavy metal passivation method in pig manure aerobic fermentation process

An aerobic fermentation and heavy metal technology, applied in the fields of application, organic fertilizer, organic fertilizer preparation, etc., can solve the problem of high activity of heavy metals, achieve the effect of increasing the content of residue state, accelerating the passivation process, and improving the comprehensive benefits of agriculture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

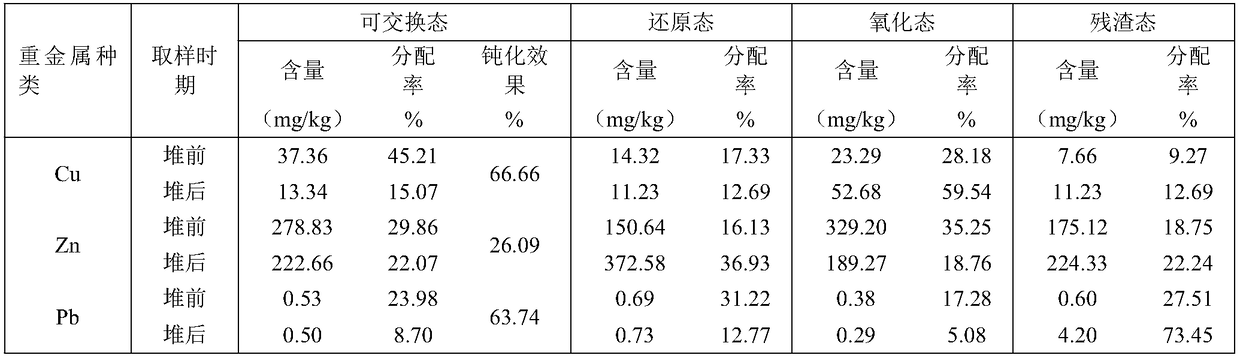

Embodiment 1

[0042] The dried corn stalks (the measured C / N ratio is 55.48, the moisture content is 22.71%) are pulverized to a degree of 1 to 3 cm, and used as a conditioner with pig manure (the measured C / N ratio is 15.58, and the moisture content is 66.3%) ) mixed, the moisture content of the mixed material is adjusted to 65%, the C / N ratio is 28.5, and the addition ratio is 9:2; biochar (raw material is sawdust) with 12% pig manure dry matter is added, the carbonization temperature is 400 ° C, and the carbonization time For 2 hours, the mixture is stacked and placed in the fermentation bed. During the heating period (50 ℃) Blast aeration once every 30 minutes. The ventilation time is 5 minutes, and the ventilation volume is 0.2m 3 min -1 m -3 After 20 days of fermentation, take it out of the fermentation bed, put it in the second fermentation field, add the same biochar as the first fermentation, add 1 / 2 of the amount added in the first fermentation, mix well, and turn it every 7 da...

Embodiment 2

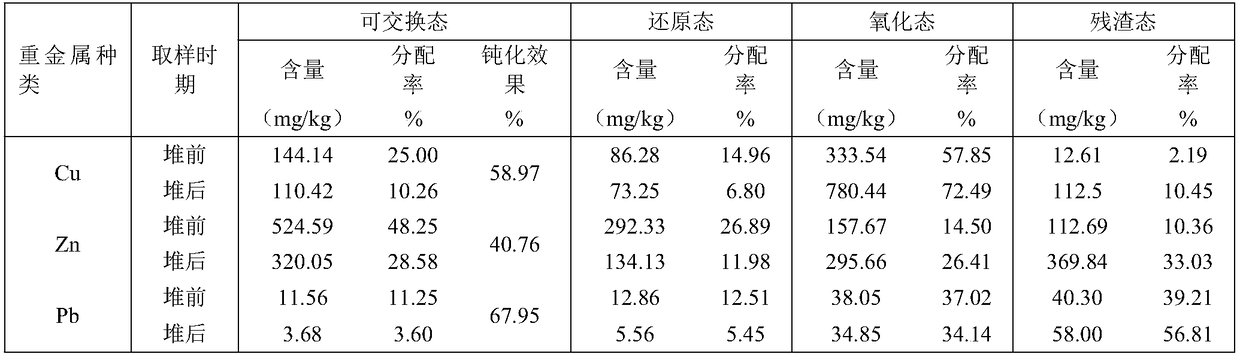

[0053] The sun-dried corn stalks (the measured C / N is 45.57, the moisture content is 12.71%) are pulverized to a degree of 1-3 cm, and used as a conditioner and pig manure (the measured C / N is 15.58, the moisture content is 58.53%) Mixing, the moisture content of the mixed material is adjusted to 68.00%, the C / N is 28.52, and the addition ratio is 8:1; add a composite microbial agent with a dry matter of pig manure of 15‰ and 24% biochar (raw material is peanut shells), and carbonize The temperature can be 500°C, and the carbonization time is 2 hours. The mixed material is stacked and placed in the fermentation bed. During the heating period (50°C) is blown every 20 minutes. Aerate once, and blow and aerate once every 30 minutes during the cooling period (3 min -1 m -3 After 20 days of fermentation, take it out of the fermentation bed, put it in the secondary fermentation field, add the same bacterial agent and biochar as the primary fermentation, and add 1 / 3 of the amount ad...

Embodiment 3

[0059] The sun-dried corn stalks (recorded C / N is 51.74, moisture content 13.37%) are pulverized to a degree of 1-3 cm, and used as conditioner and pig manure (recorded C / N is 14.42, moisture content 66.33%) ) mixed, the moisture content of the mixed material is adjusted to 65.00%, the C / N is 26.52, and the addition ratio is 7:1; biological humic acid with a dry matter amount of pig manure of 2.5‰ is added, and the mixed material is stacked and placed in an aerobic fermentation bed During the heating period (50°C), blow and aerate once every 20 minutes; The time is 5min, the ventilation volume is 0.15m 3 min -1 m -3 After 20 days of fermentation, take it out of the fermentation bed, place it in the secondary fermentation field, add the same biological humic acid as that of the primary fermentation, and add 1 / 3 of the amount added in the primary fermentation, mix well, and turn the pile every 4 days , after 30 days of secondary aerobic fermentation, the appearance of the fer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com