A kind of method preparing taurine by sodium isethionate

A technology of sodium isethionate and taurine, applied in the preparation of sulfonic acid, preparation of sulfonate, organic chemistry, etc., can solve the problems of harsh reaction conditions for aminolysis, high energy consumption in the reaction process, and high production cost, Achieve the effect of improving electrophilic properties, shortening reaction time, and mild reaction temperature and pressure conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

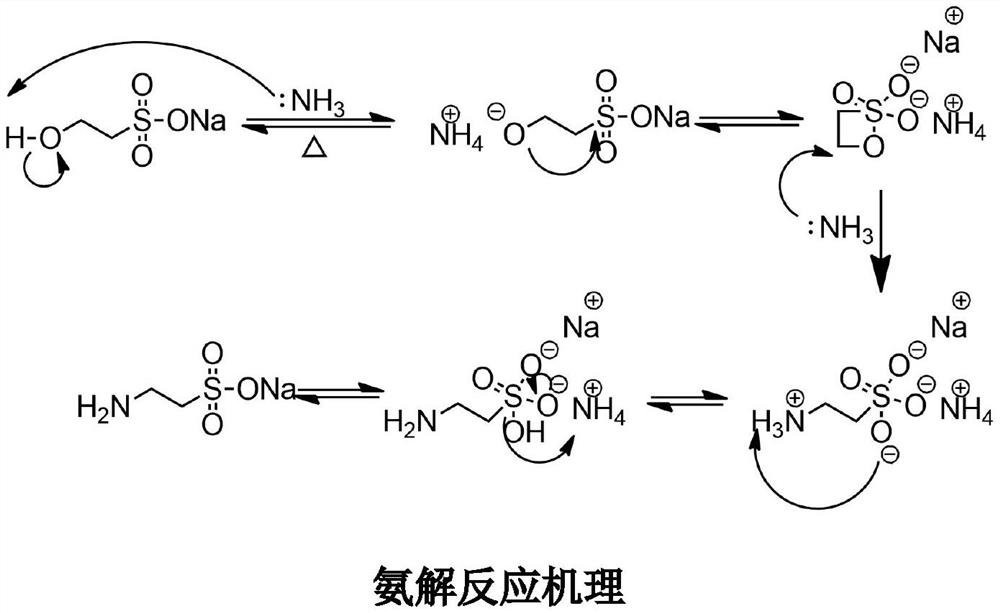

Method used

Image

Examples

Embodiment 1

[0039] 696g of sodium isethionate solution (15.0wt%) was placed in a 1L high-pressure reactor, and a certain amount of liquid ammonia was introduced to make the concentration of liquid ammonia reach 24.0wt%, and then 0.104g (0.1wt%) of Na 2 MoO 4 Catalyst and 0.104g CuCl co-catalyst, the temperature of the reaction system was raised to 160° C., the system pressure was 9.8 MPa, and the reaction was carried out for 30 minutes. The yield of sodium taurate obtained by the ammonolysis reaction was 92.5%. After the reaction solution was flashed at 100°C to remove ammonia, it was evaporated and concentrated to increase the concentration of sodium taurine to 40wt%, and then a certain amount of concentrated sulfuric acid was added at 80°C to adjust the pH of the system to 7.8, and then cooled to 20°C Crystallization, the one-way yield of taurine after crystallization is 75.0%, and the mother liquor can be applied mechanically again to ammonolysis reaction, and the total yield of taurin...

Embodiment 2

[0041] 740g of sodium isethionate solution (20.0wt%) was placed in a 1L high-pressure reactor, and a certain amount of liquid ammonia was introduced to make the concentration of liquid ammonia reach 21.0wt%, and then 0.296g (0.2wt%) (NH 4 ) 2 MoO 4Catalyst and 0.148g CuCl co-catalyst, the reaction system was heated to 140° C., the system pressure was 7.2 MPa, and the reaction was carried out for 20 minutes. The yield of sodium taurate obtained in this step was 89.0%. After the reaction solution was flashed at 100°C to remove ammonia, it was evaporated and concentrated to increase the concentration of sodium taurine to 38wt%, and then a certain amount of concentrated sulfuric acid was added at 60°C to adjust the pH of the system to 8.2, and then cooled to 30°C Crystallization, the one-way yield of taurine after crystallization is 70.0%, and the mother liquor can be applied mechanically again to ammonolysis reaction, and the total yield of taurine after mechanical application i...

Embodiment 3

[0043] 724g of sodium isethionate solution (18.0wt%) was placed in a 1L high-pressure reactor, and a certain amount of liquid ammonia was introduced to make the concentration of liquid ammonia reach 18.0wt%, and then 0.065g (0.05wt%) Li 2 MoO 4 Catalyst and 0.046g CuCl co-catalyst, the reaction system was heated to 120° C., the system pressure was 5.1 MPa, and the reaction was carried out for 60 minutes. The yield of sodium taurate obtained in this step reaction was 95.0%. After the reaction solution was flashed at 100°C to remove ammonia, it was evaporated and concentrated to increase the concentration of sodium taurine to 35wt%, and then a certain amount of concentrated sulfuric acid was added at 90°C to adjust the pH of the system to 7, and then cooled to 20°C Crystallization, the one-way yield of taurine after crystallization is 73.2%, and the mother liquor can be applied mechanically again to ammonolysis reaction, and the total yield of taurine after mechanical applicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com