Ceramic-based composite solid-state electrolyte and preparation method thereof

A solid electrolyte, ceramic matrix composite technology, applied in solid electrolytes, non-aqueous electrolytes, circuits, etc., can solve the problems of difficult preparation of solid electrolytes, low lithium ion conductivity, poor ability to wet electrodes, etc. Good ability, high ionic conductivity, and the effect of inhibiting lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

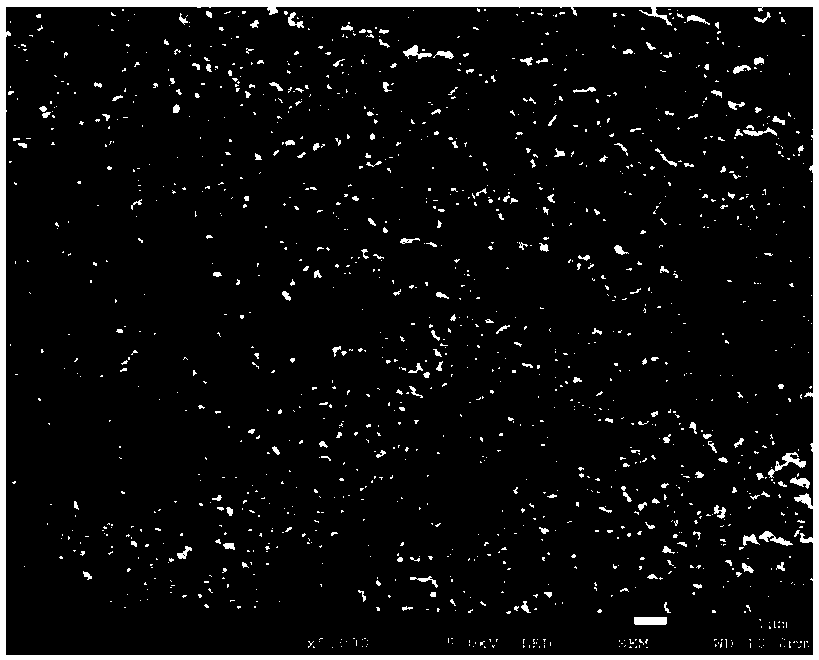

[0037] A ceramic matrix composite solid electrolyte, the composite solid electrolyte includes Li1+xAlxTi2-x(PO4)3, polyvinylidene fluoride, lithium perchlorate and gel electrolyte, its thickness is 10-150μm, room temperature ionic conductivity is 1 *10 -4 S / cm~1*10 -3 S / cm, the electrochemical window is greater than 5.0V.

[0038] The mass proportion of Li1+xAlxTi2-x(PO4)3 in the composite solid electrolyte is 80%.

[0039] The mass proportion of polyvinylidene fluoride in the composite solid electrolyte is 5%.

[0040] The mass proportion of lithium perchlorate in the composite solid electrolyte is 10%.

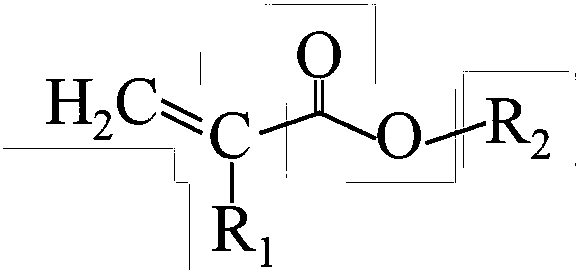

[0041] The gel electrolyte contains polyethylene glycol diacrylate, electrolyte, methacryloxypropyltrimethoxysilane and azobisisobutyronitrile, and the mass ratio of the gel electrolyte in the composite solid electrolyte is 5% ;

[0042] Wherein, polyethylene glycol diacrylate accounts for 3% by mass in the gel electrolyte.

[0043] The mass ratio of methacryloxypropyl...

Embodiment 2

[0058] A ceramic-based composite solid electrolyte, the composite solid electrolyte includes Li7La3Zr2O12, polyvinylidene fluoride-hexafluoropropylene, bis(trifluoromethylsulfonate)imide lithium and gel electrolyte, its thickness is 10-150μm, room temperature ionic The conductivity is 1*10 -4 S / cm~1*10 -3 S / cm, the electrochemical window is greater than 5.0V.

[0059] The mass proportion of Li7La3Zr2O12 in the composite solid electrolyte is 60%.

[0060] The mass proportion of lithium bis(trifluoromethanesulfonate)imide in the composite solid state electrolyte is 20%.

[0061] The mass proportion of vinylidene fluoride-hexafluoropropylene in the composite solid electrolyte is 10%.

[0062] The gel electrolyte includes tetraethylene glycol dimethacrylate, electrolyte, butyl acrylate and azobisisoheptanonitrile, and the mass ratio of the gel electrolyte in the composite solid electrolyte is 10%;

[0063] Wherein, tetraethylene glycol dimethacrylate accounts for 4% by mass in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Sub-conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com