Titanium-based composite material for visible light catalytic degradation of rhodamine B and preparation thereof

A titanium-based composite material, catalytic degradation technology, applied in special compound water treatment, physical/chemical process catalyst, organic compound/hydride/coordination complex catalyst, etc., can solve problems such as human skin damage, and achieve the cost of raw materials Low, synergistic improvement, high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of active TiO by sol-gel method 2 Nano powder

[0037] Solution A: Take a clean beaker and place it on a magnetic stirrer, use a graduated cylinder to measure 5 mL of deionized water and pour it into the beaker, while stirring slowly, measure 2.5 mL of glacial acetic acid and 5 mL of absolute ethanol in turn to add In a beaker, cover the beaker with plastic wrap, stir for 10 min to form A solution;

[0038] Solution B: Take another clean beaker and put it on another magnetic stirrer, use a dry measuring cylinder to measure 5 mL of butyl titanate into the beaker, add 20 mL of absolute ethanol under vigorous stirring, and cover with plastic wrap beaker, stirred for 10 min to form B solution;

[0039] Under vigorous stirring, slowly pour B solution into A solution to obtain a milky white transparent sol, let the colloid stand for 4 hours, and dry it in an oven at a low temperature of 60°C for 24 hours to obtain yellow crystals, which are ground into powder wi...

Embodiment 2

[0041] TiO 2 / Ag + Preparation of nanocomposites

[0042] Solution A: Take a 50 mL beaker, measure 10 mL deionized water into the beaker, add 1g TiO 2 , 0.214 g of AgNO 3 solid, stir until completely dissolved;

[0043] Solution B: take another 50 mL beaker, measure 20 mL deionized water into the beaker, and stir for 10 min;

[0044] Under stirring at room temperature, slowly add liquid B into liquid A, stir for 45 min, centrifuge, discard the supernatant, wash the precipitate with deionized water 4 times, and dry at 60°C to obtain TiO 2 / Ag + nanocomposites.

Embodiment 3

[0046] TiO 2 / Ag + Preparation of / IL nanocomposites

[0047] Liquid A: Take a 50 mL beaker, measure 10 mL of deionized water and pour it into the beaker, and add 1 g of TiO prepared in Example 1 in sequence 2 Nanopowder, 0.214 g AgNO 3 Solid, stir until completely dissolved;

[0048] Solution B: take another 50 mL beaker, measure 20 mL deionized water into the beaker, then add 0.02 g 1-butyl-2-methyl-imidazolium chloride salt, stir for 10 min;

[0049] Under stirring at room temperature, slowly add liquid B into liquid A, stir for 45 min, centrifuge, discard the supernatant, wash the precipitate with deionized water 4 times, and dry at 60°C to obtain TiO 2 / Ag + / IL nanocomposite a.

[0050] performance testing

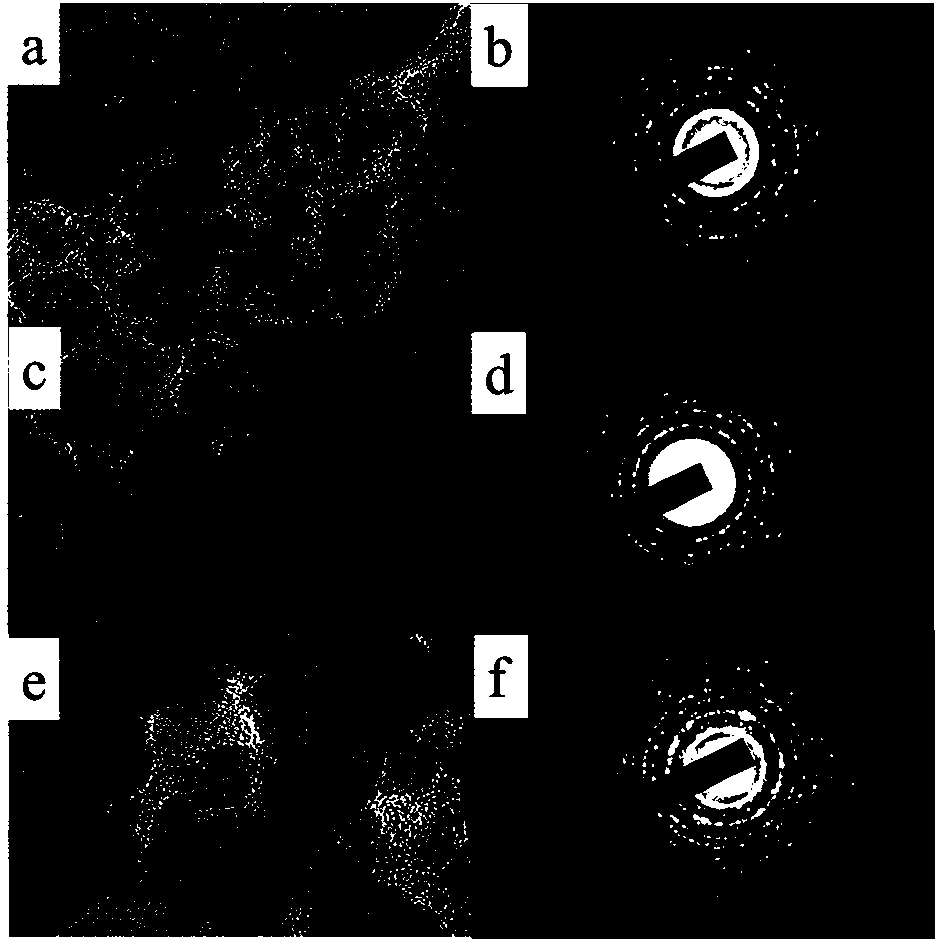

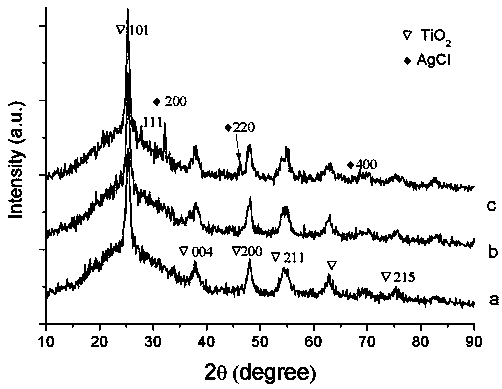

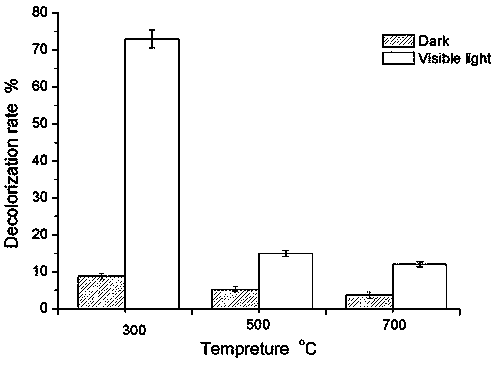

[0051] Three kinds of series TiO prepared by embodiment 1-3 2 Based nanomaterials were ground in an agate mortar, uniformly dispersed in an ethanol solution, and scanned by a transmission electron microscope. The results were as follows: figure 1 As shown, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com