Production method of copper sulfate

A production method, copper sulfate technology, applied in the direction of copper sulfate, etc., can solve the problems of not meeting the copper sulfate electroplating grade standard, containing more impurities and metal ions, and the quality of crude copper sulfate is not up to standard, so as to avoid unstable reaction, Ease of filtration and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

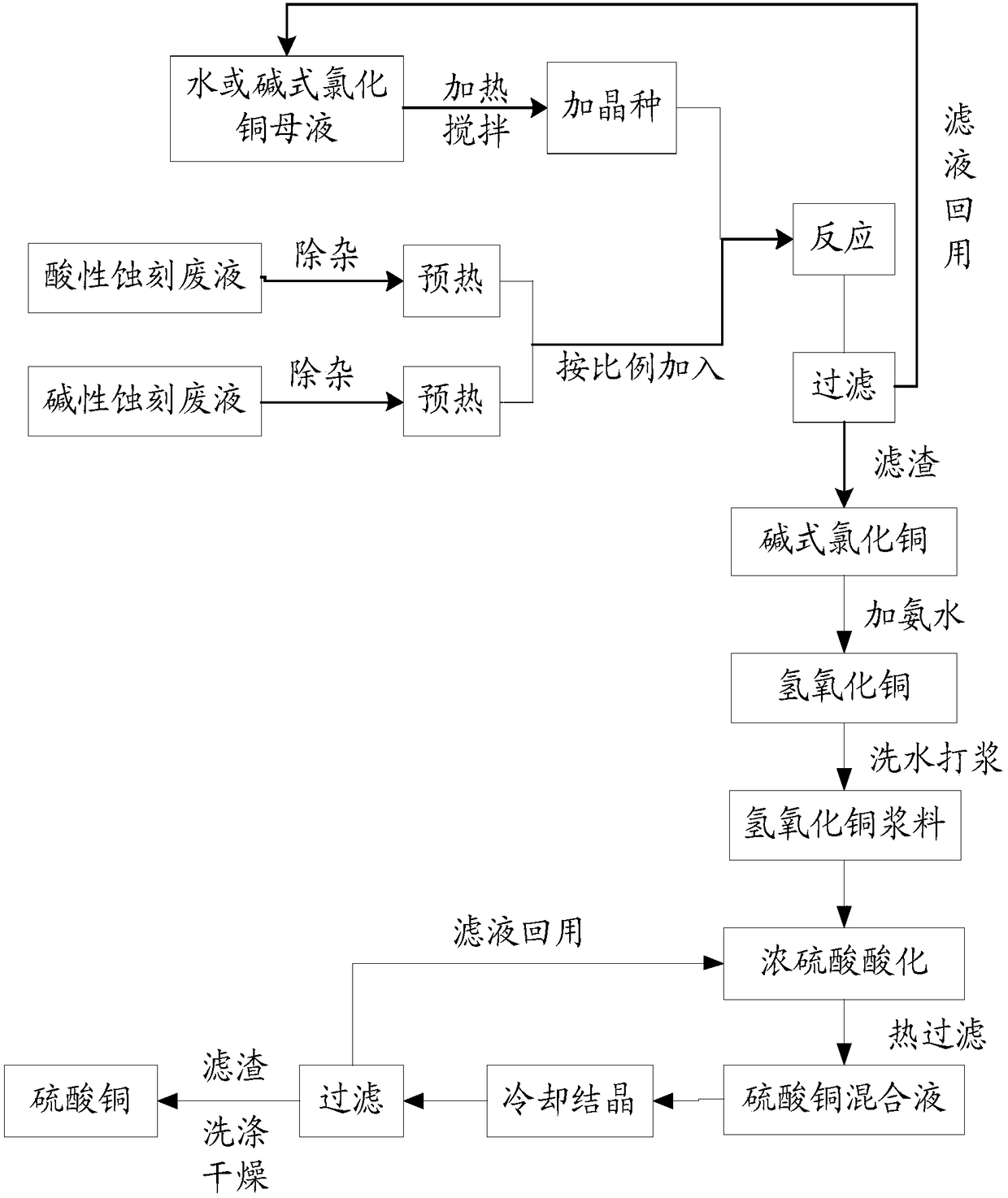

Method used

Image

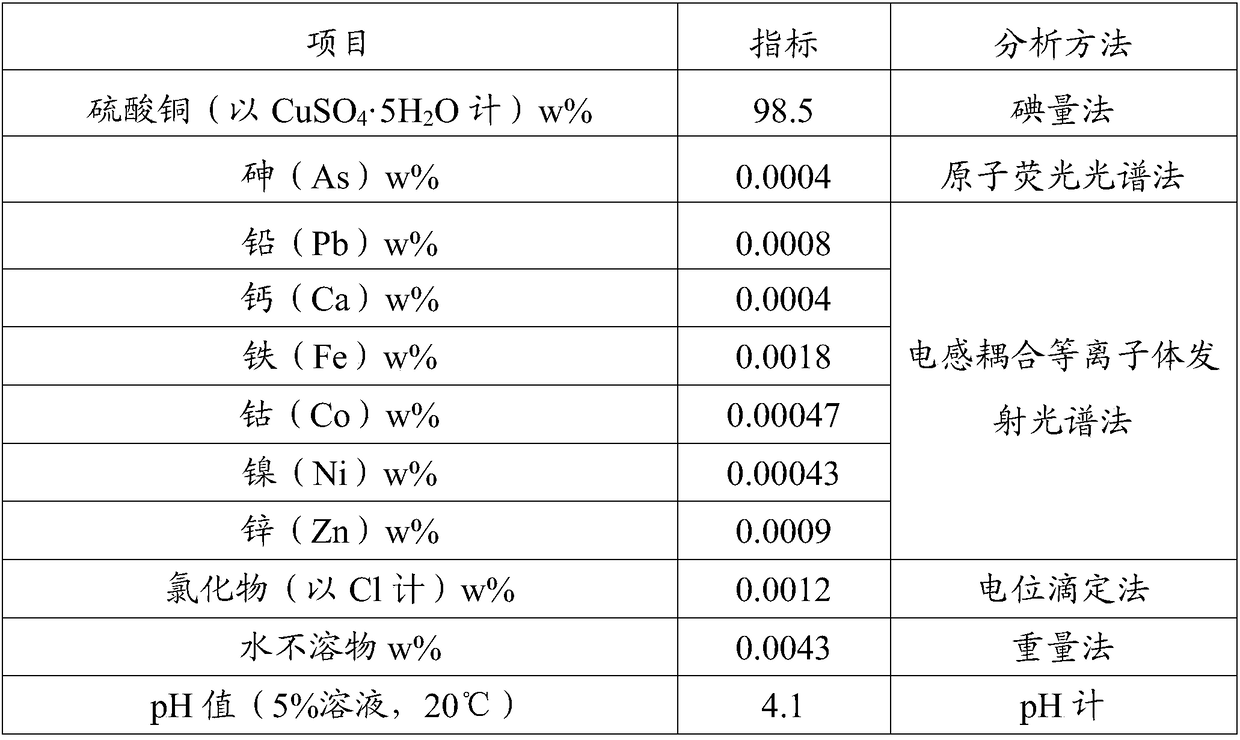

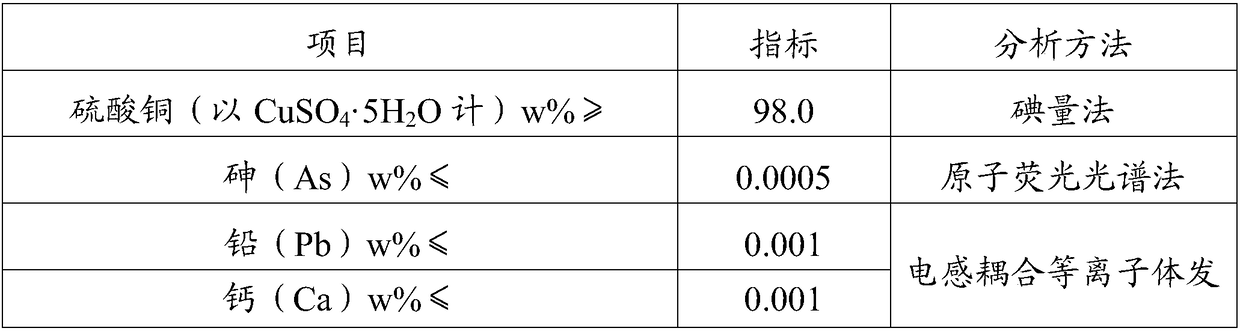

Examples

Embodiment 1

[0062] 1. Removal of impurities in acidic etching waste liquid:

[0063] Add 5m3 tap water in the sodium chlorate dispensing tank, then add 2 tons of solid sodium chlorate, stir to be mixed with sodium chlorate solution.

[0064] Start the acid etching waste liquid lifting pump, start the press filtration, the filtrate produced overflows to the acid etching waste hydraulic pressure filter tank, and lifts the filtrate to the acid etching waste liquid purification tank through the filter pressure tank lifting pump for purification treatment.

[0065] Turn on the mixer, add sodium chlorate solution to the acid etching waste liquid purification tank to remove the Cu in the acid etching waste liquid + , Fe 2+ Oxidized to Cu 2+ , Fe 3+ , according to the color of the acidic etching waste liquid to judge the oxidation end point, when the acidic etching waste liquid is green and transparent, it is the oxidation end point, and there is no need to continue to add sodium chlorate soluti...

Embodiment 2

[0097] Embodiment 2 is substantially the same as Example 1, except that the basic cupric chloride mother liquor produced in Example 1 replaces the tap water in Example 1.

Embodiment 3

[0099] Embodiment 3 is basically the same as Embodiment 2, the difference lies in the following aspects:

[0100] 1), in the step of removing impurities in the acidic etching waste liquid, adding ammonia water to the purification tank will adjust the pH value of the acidic etching waste liquid to be different, the pH value of embodiment 2 is 1.8, and the pH value of embodiment 3 is 1.9.

[0101] 2) The raw materials are different, specifically:

[0102] The Baume degree of the acidic etching waste liquid before impurity removal is 27Be°, the pH value is -0.5, the Baume degree after the impurity removal is 26Be°, and the pH value is 1.5;

[0103] The Baume degree of the alkaline etching waste liquid before impurity removal is 16Be°, and the pH value is 10.5, and the Baume degree after impurity removal is 15Be°, and the pH value is 9.0.

[0104] 3) The preheating temperature is different, specifically: the preheating temperature of Example 2 is 45°C, and the preheating temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com