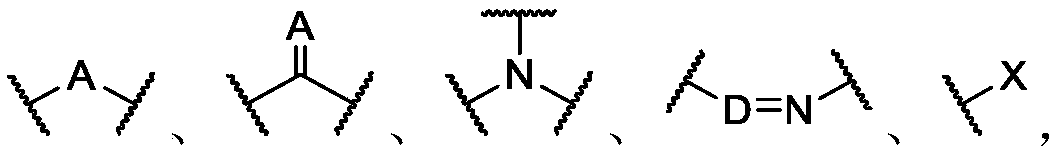

Dynamic polymer with hybrid cross-linked structure and application thereof

A hybrid cross-linking and polymer technology, applied in the field of smart polymers, can solve the problems of lack of dynamic chemical cross-linking, hard cross-linking polymers, and inability to reflect the cross-linking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

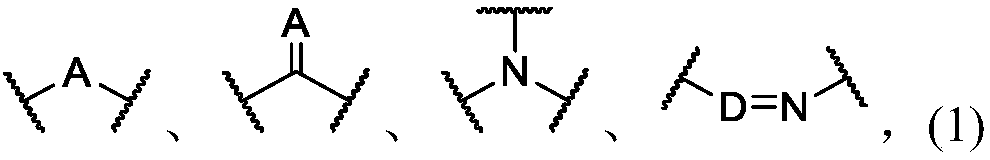

Method used

Image

Examples

preparation example Construction

[0122] In the preparation process of dynamic polymer foaming materials, three methods of mechanical foaming, physical foaming and chemical foaming are mainly used to foam dynamic polymers.

[0123] Among them, the mechanical foaming method is to introduce a large amount of air or other gases into the emulsion, suspension or solution of the polymer with the help of strong stirring during the preparation of the dynamic polymer to make it a uniform foam, and then through physical Or chemical changes make it gel and solidify to become a foam material. In order to shorten the molding cycle, air can be introduced and emulsifiers or surfactants can be added.

[0124] Wherein, the physical foaming method is to utilize physical principles to realize the foaming of the polymer in the preparation process of the dynamic polymer, and it generally includes the following five methods: (1) inert gas foaming method, that is, after adding Press the inert gas into the molten polymer or pasty ma...

Embodiment 1

[0190] Mix trimethyl borate and dimethylmethoxy-3-butene silane in a molar ratio of 1:3, heat to 60°C and stir to dissolve, then add a small amount of water to continue the reaction for 4 hours to obtain a silicon borate containing bonded trivinyl compound 1a.

[0191] Mix 1,5-hexadien-3-ol and ethyl isocyanate in an equimolar ratio, use triethylamine as a catalyst, and react in dichloromethane to obtain compound 1b with a carbamate group in the side group.

[0192] Mix compound 1a, compound 1b and trimethylolpropane tris(2-mercaptoacetate) according to the molar ratio of 1:1:2, then add 1wt% organobentonite and 1wt% bentonite, shake and mix evenly, and place Ultraviolet radiation in the ultraviolet crosslinking apparatus for 8 hours, a dynamic polymer containing ordinary covalent crosslinks, borate silicon ester bonds and side hydrogen bond groups was obtained.

[0193] The polymer product can be used as a sheet or coating with certain energy-absorbing properties and tear re...

Embodiment 2

[0195] Organopolysiloxanes (molecular weight about 8000), 5-mercaptomethyluracil, 3-mercaptopropyltrimethoxysilane and 1,12-dimercaptododecane with terminal olefin groups in the side groups according to the double bond and The molar ratio of each mercapto compound is mixed at 22:10:10:1, and 0.2wt% of photoinitiator benzoin dimethyl ether (DMPA) is added. After stirring fully, put it in an ultraviolet crosslinking apparatus for ultraviolet radiation for 4 hours to obtain the prepared An organopolysiloxane containing common covalent crosslinks and pendant hydrogen bonding groups.

[0196] The above-mentioned organopolysiloxane and trimethyl borate containing side hydrogen bond groups according to Si-OCH 3 The molar ratio of the group and the B-OR group is mixed at 1:1. After heating up to 80°C and mixing evenly, add 4ml of deionized water, add a small amount of acetic acid dropwise, and then add 5wt% graphene powder. After shaking and mixing evenly, Polymerization is carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com