Traditional Chinese medicine hemsley rockvine root processing method capable of keeping pharmaceutical-effect active ingredient

A technology of active ingredients and processing methods, which is applied in the field of traditional Chinese medicine trefoil processing that retains medicinal active ingredients, can solve problems such as high cost, high production cost, and loss of medicinal active ingredients, so as to prevent loss or damage and ensure Speed and effect, boost retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

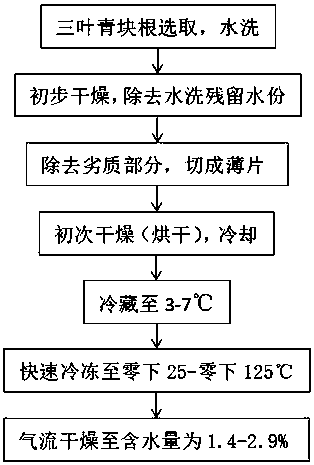

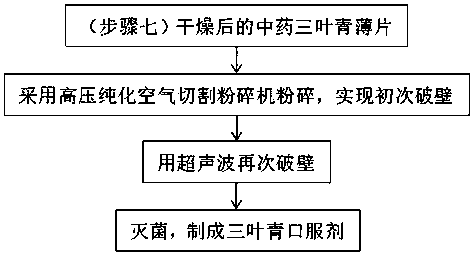

[0047] Step 1: Select fresh clover root tubers and wash them with water;

[0048] Step 2: Preliminarily dry the washed Pseudomonas clover root at 65°C under a nitrogen atmosphere, remove the water remaining on the surface due to water washing, and take it out after cooling;

[0049] Step 3: Cut off the inferior part, and cut the remaining part into thin slices with a thickness of 2.5mm;

[0050] Step 4: Dry the Clover flakes at 65°C under a nitrogen atmosphere for 20 minutes for the first time, and take them out after cooling;

[0051] Step 5: placing the first dried Clover flakes in a dry refrigerator and refrigerating them to 5°C;

[0052] Step 6: freezing with liquid nitrogen, freezing the refrigerated Clover flakes to below minus 55°C within 15 minutes;

[0053] Step 7: Blow a dry mixed gas of argon and helium with a molar ratio of 1:1 at 55°C on the surface of the frozen Clover flakes at a gas flow rate of 1.4m / s, and further dry to contain The water content is 2.15%, ...

Embodiment 2

[0055] Step 1: Select fresh clover root tubers and wash them with water;

[0056] Step 2: Preliminarily dry the washed Clover root at 55°C under a nitrogen atmosphere, remove the water remaining on the surface due to water washing, and take it out after cooling;

[0057] Step 3: Cut off the inferior part, and cut the remaining part into thin slices with a thickness of 1.5mm;

[0058] Step 4: Dry the Clover flakes at 60°C under a nitrogen atmosphere for 15 minutes for the first time, and take them out after cooling;

[0059] Step 5: placing the Clover flakes after the initial drying in a dry refrigerator to refrigerate to 3°C;

[0060] Step 6: Vitrification ultrafast freezing is used to freeze the refrigerated Clover flakes to minus 125°C within 3 minutes;

[0061] Step 7: Blow a dry mixed gas of argon and helium at a molar ratio of 0.5:1 at 35°C on the surface of the frozen Clover flakes at a gas flow rate of 0.5m / s, and further dry until the surface contains The water cont...

Embodiment 3

[0063] Step 1: Select fresh clover root tubers and wash them with water;

[0064] Step 2: Preliminarily dry the washed Pseudomonas clover root at 75°C under a nitrogen atmosphere, remove the water remaining on the surface due to water washing, and take it out after cooling;

[0065] Step 3: Cut off the inferior part, and cut the remaining part into slices with a thickness of 3.5mm;

[0066] Step 4: Dry the Clover flakes at 70°C under a nitrogen atmosphere for 25 minutes for the first time, and take them out after cooling;

[0067] Step 5: placing the Clover flakes after the initial drying in a dry refrigerator to refrigerate to 7°C;

[0068] Step 6: Using gas turbo expansion refrigeration, freezing the refrigerated Clover flakes to minus 25°C within 35 minutes;

[0069] Step 7: Blow a dry mixed gas of argon and helium with a molar ratio of 2:1 at 65°C on the surface of the frozen Clover flakes at a gas flow rate of 2 m / s, and further dry to the water content It is 2.9%, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com