Preparation method of rose-shaped MoS2 nanoflower

A nano-flower and rose technology, applied in chemical instruments and methods, physical/chemical process catalysts, molybdenum sulfide, etc., can solve the problems of product size and morphology that are difficult to control, harsh reaction conditions at high temperature, and poor particle dispersion. To achieve the effect of simple equipment, low cost and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A rose-like MoS 2 The preparation method of nanoflowers comprises the following preparation steps in turn:

[0032] (1) Weigh 1.236g ammonium molybdate tetrahydrate and dissolve in 20ml deionized water to make solution A; weigh 0.75g thioacetamide and dissolve it in 20ml deionized water to make solution B;

[0033] (2) Mix solutions A and B as a reaction solution, transfer them to a reactor for hydrothermal reaction, the reaction temperature is 170 °C, and the reaction time is 15 hours, and the rose-shaped MoS 2 The suspension reaction solution of nanoflowers;

[0034] (3) Centrifuge the obtained suspension reaction solution, and then wash the precipitate with deionized water and absolute ethanol respectively;

[0035] (4) Dry the precipitate in a vacuum drying oven at 50°C for 5 hours to finally obtain black molybdenum disulfide powder, and the yield is as high as 97.2%.

[0036] Rose-like MoS prepared in this example 2 Scanning electron microscope image of nanoflo...

Embodiment 2

[0044] A rose-like MoS 2 The preparation method of nanoflowers comprises the following preparation steps in turn:

[0045] (1) Weigh 1.236g ammonium molybdate tetrahydrate and dissolve in 20ml deionized water to make solution A; weigh 0.15g thioacetamide and dissolve it in 20ml deionized water to make solution B;

[0046](2) Mix solutions A and B as a reaction solution, transfer them to a reactor for hydrothermal reaction, the reaction temperature is 160 °C, and the reaction time is 17 hours, and the rose-like MoS 2 The suspension reaction solution of nanoflowers;

[0047] (3) Centrifuge the obtained suspension reaction solution, and then wash the precipitate with deionized water and absolute ethanol respectively;

[0048] (4) Dry the precipitate in a vacuum drying oven at 50°C for 5 hours to finally obtain black molybdenum disulfide powder, and the yield is as high as 98.0%.

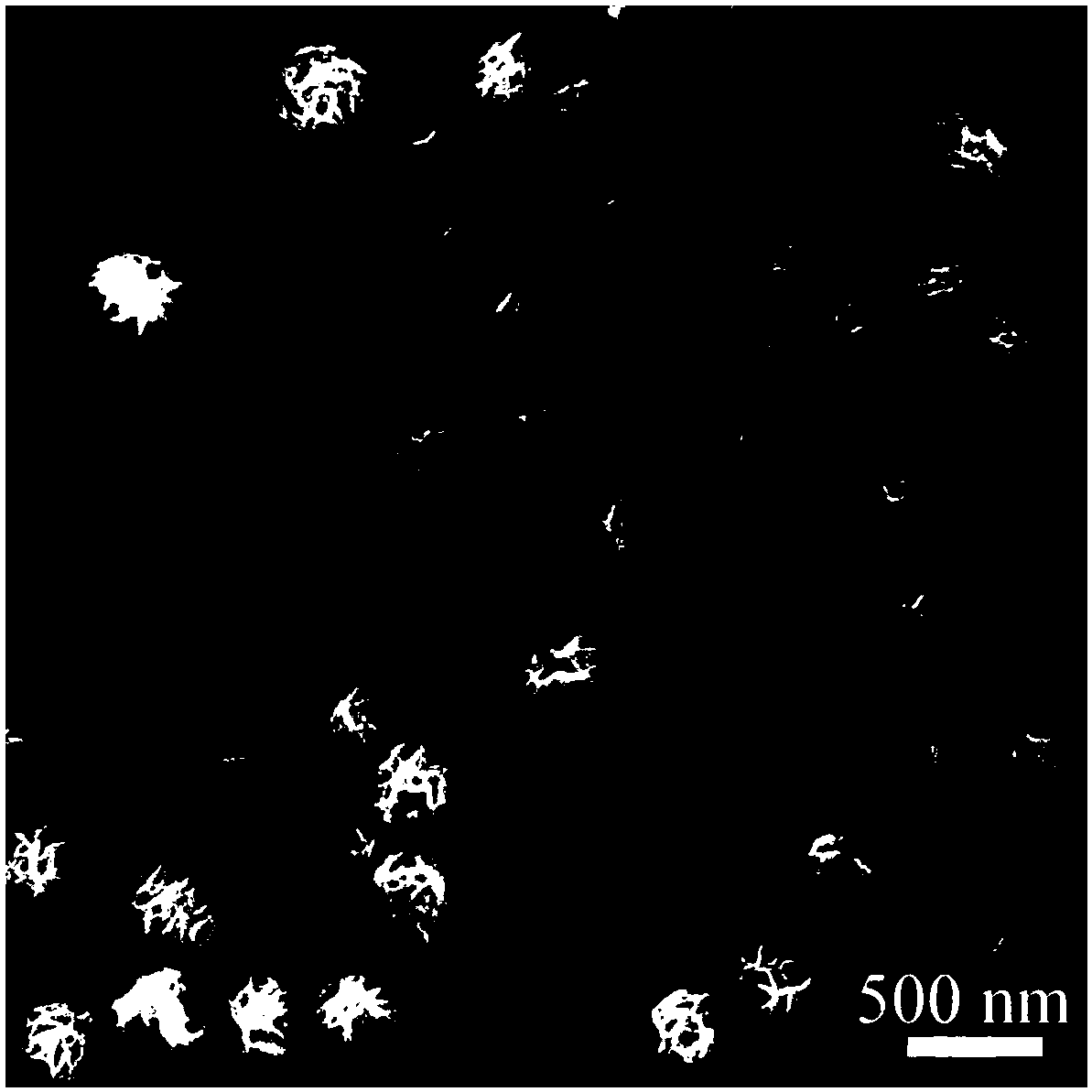

[0049] Rose-like MoS prepared in this example 2 Scanning electron microscope image of nanoflower...

Embodiment 3

[0051] A rose-like MoS 2 The preparation method of nanoflowers comprises the following preparation steps in turn:

[0052] (1) Weigh 0.2472g ammonium molybdate tetrahydrate and dissolve it in 20ml deionized water to make solution A; weigh 0.15g thioacetamide and dissolve it in 20ml deionized water to make solution B;

[0053] (2) Mix solutions A and B as a reaction solution, transfer them to a reactor for hydrothermal reaction, the reaction temperature is 190 ° C, and the reaction time is 15 hours, and the rose-shaped MoS 2 The suspension reaction solution of nanoflowers;

[0054] (3) Centrifuge the obtained suspension reaction solution, and then wash the precipitate with deionized water and absolute ethanol respectively;

[0055] (4) Dry the precipitate in a vacuum drying oven at 45°C for 5.5 hours to finally obtain black molybdenum disulfide powder with a yield as high as 97.6%.

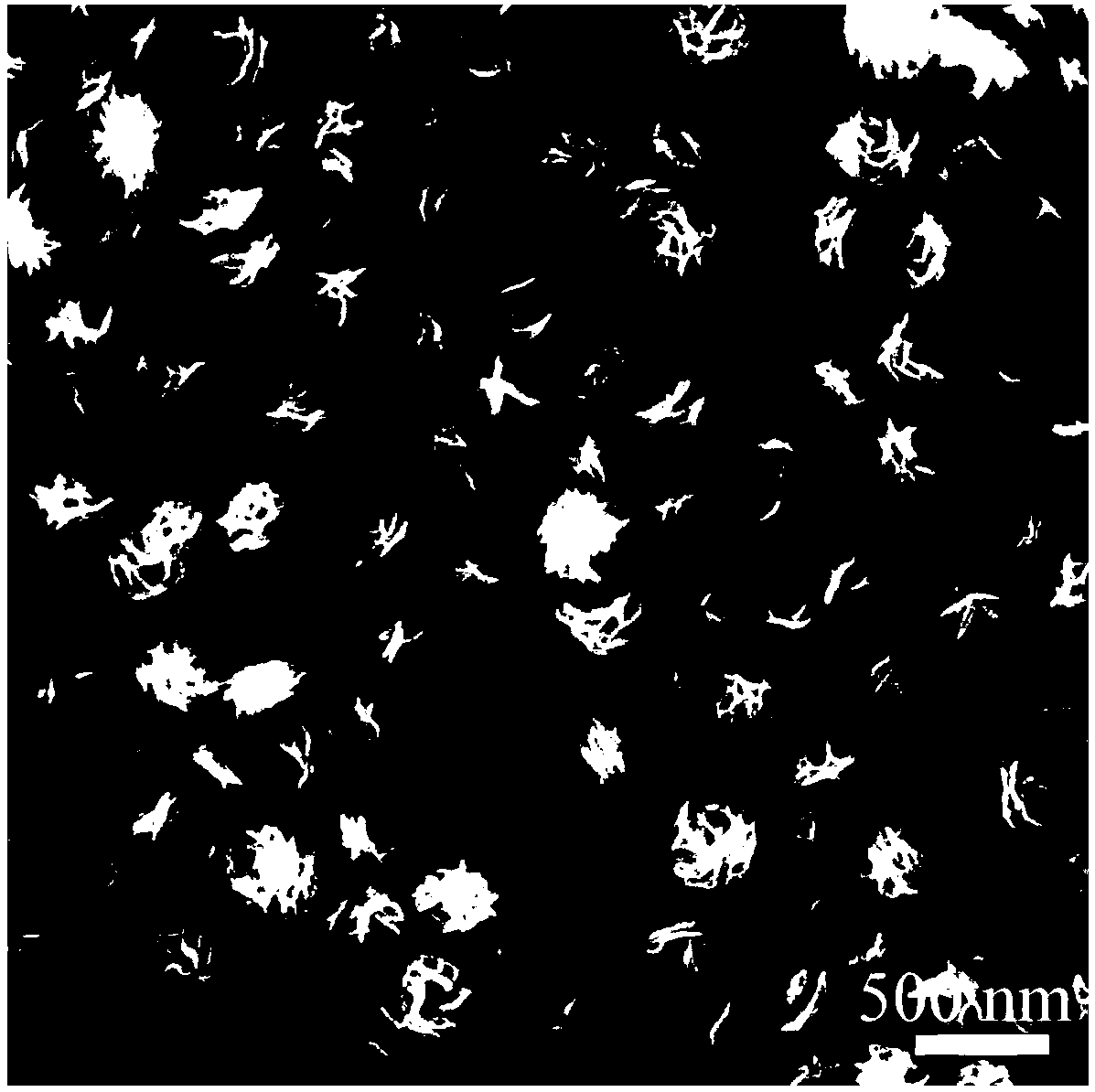

[0056] Rose-like MoS prepared in this example 2 Scanning electron microscope image of nanof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com