Method for separating methylnaphthalene enrichment liquid from mixed C10 heavy aromatic composition

A methylnaphthalene enrichment solution and methylnaphthalene enrichment technology, which is applied to the purification/separation of hydrocarbons and hydrocarbons, crystallization purification/separation, etc., can solve the problem of low yield, prevent thermal cracking, improve Stability, effect of improving oxidation resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

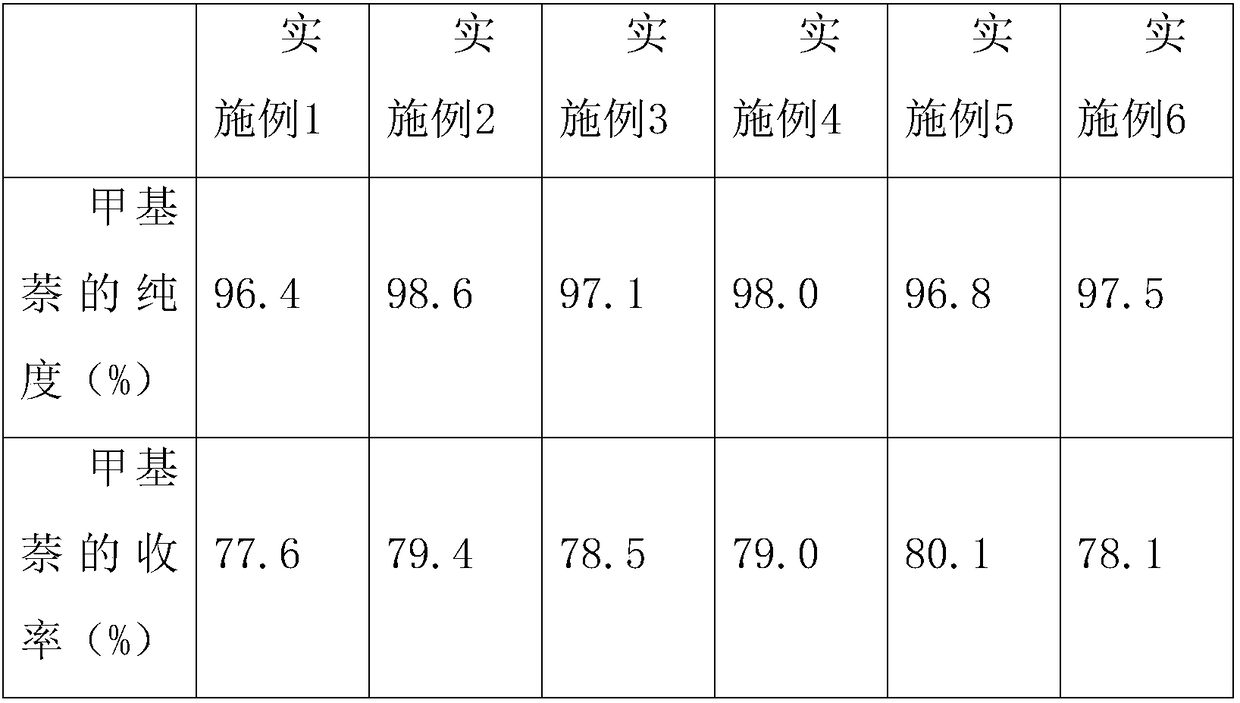

Examples

Embodiment 1

[0026] (1) Remove the heavy carbon decaaromatics from durene, naphthalene and low carbon decaaromatic solvents, and distill under reduced pressure at a tower top temperature of 132°C, a tower bottom temperature of 198°C, and a vacuum of -0.009MPa 60min, the obtained methylnaphthalene enrichment liquid, according to the mass ratio of methylnaphthalene enrichment liquid and graphene, ethanolamine is 1:0.001:0.05, adds the ethanolamine containing graphene, mixes uniformly, forms the formazan modified by graphene base naphthalene enrichment solution.

[0027] (2) Transfer the graphene-modified methylnaphthalene-enriched liquid to a reboiler, and reboil the methylnaphthalene-enriched liquid at a vacuum of -0.0085MPa in a batch vacuum rectification system , the temperature at the top of the tower is 80°C, the temperature at the bottom of the tower is 150°C, the absolute pressure at the top of the tower is 20KPa, the reflux ratio is 1:5, vacuum distillation is 40min, and the unconden...

Embodiment 2

[0031](1) Remove heavy carbon decaaromatics from durene, naphthalene and low carbon decaaromatic solvents, and distill under reduced pressure under the condition that the temperature at the top of the tower is 133°C, the temperature at the bottom of the tower is 200°C, and the degree of vacuum is -0.009MPa 80min, the obtained methylnaphthalene enrichment liquid, according to the mass ratio of methylnaphthalene enrichment liquid and graphene, ethanolamine is 1:0.003:0.1, adds the ethanolamine containing graphene, mixes evenly, forms the formazan modified by graphene base naphthalene enrichment solution.

[0032] (2) Transfer the graphene-modified methylnaphthalene-enriched liquid to a reboiler, and reboil the methylnaphthalene-enriched liquid at a vacuum of -0.0085MPa in a batch vacuum rectification system , the temperature at the top of the tower is 85°C, the temperature at the bottom of the tower is 155°C, the absolute pressure at the top of the tower is 50KPa, the reflux rat...

Embodiment 3

[0036] (1) Remove durene, naphthalene and low-carbon deca-aromatic hydrocarbons as solvents, and distill under reduced pressure at a tower top temperature of 132.5°C, a tower bottom temperature of 199°C, and a vacuum of -0.009MPa 70min, the obtained methylnaphthalene enrichment liquid, according to the mass ratio of methylnaphthalene enrichment liquid and graphene, ethanolamine is 1:0.002:0.06, adds the ethanolamine containing graphene, mixes uniformly, forms the formazan modified by graphene base naphthalene enrichment solution.

[0037] (2) Transfer the graphene-modified methylnaphthalene-enriched liquid to a reboiler, and reboil the methylnaphthalene-enriched liquid at a vacuum of -0.0085MPa in a batch vacuum rectification system , the temperature at the top of the tower is 82°C, the temperature at the bottom of the tower is 153°C, the absolute pressure at the top of the tower is 40KPa, the reflux ratio is 1:6, vacuum distillation is 50min, and the uncondensed gas phase is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com