A kind of Bayer method red mud improver and using method thereof

A Bayer process red mud and modifier technology, applied in the environmental field, can solve the problems of high cost, difficult to popularize and use on a large scale, and many modifiers, etc., and achieve the effects of low cost, large-scale application, and short improvement cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

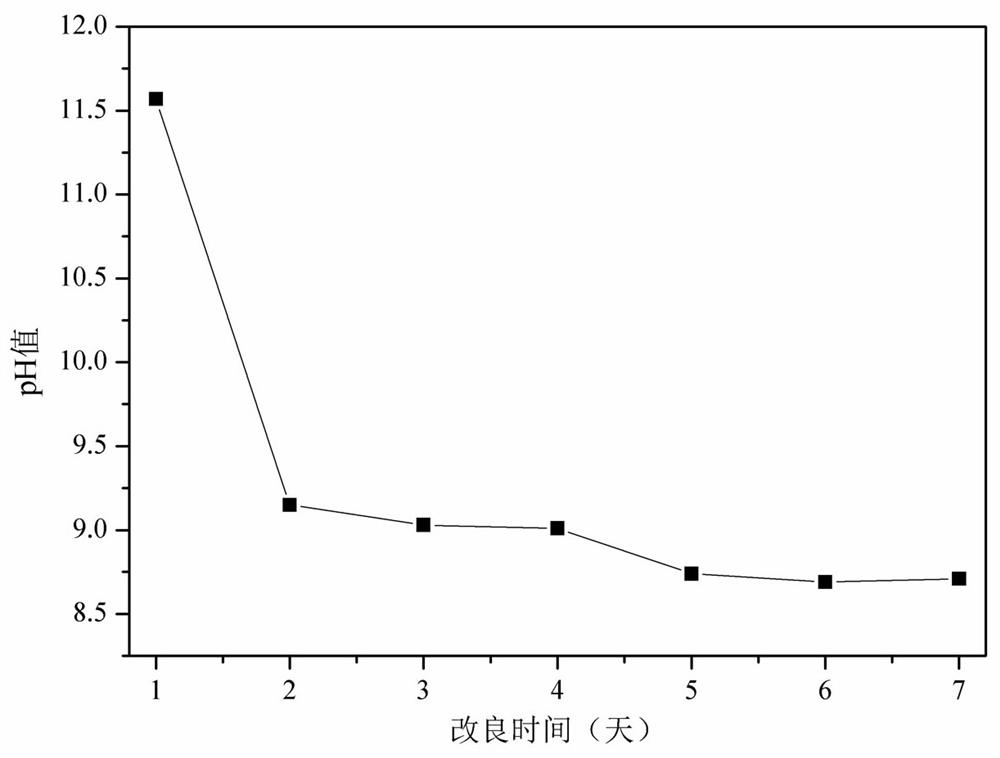

[0029] Take 5 g of glucose, 3 g of yeast extract, 10 g of starch and 5 g of calcium dihydrogen phosphate, add 1000 g of distilled water and mix to form an aqueous solution to obtain a liquid modifier. The Bayer process red mud, which is dried, ground, and passed through an 18-mesh sieve, is mixed with the liquid modifier in a ratio of 1:1 according to w:v, and then allowed to stand at 30°C for 3 days to form a Bayer process red mud solution.

[0030] After drying, the bagasse, crushed and passed through an 18-mesh sieve, is added to the Bayer process red mud solution in step 1, and allowed to stand at 30°C for 4 days to obtain an improved Bayer process red mud. The mass ratio of bagasse to Bayer process red mud is 1:18. Then the modified Bayer process red mud was dried and ground at room temperature, and the pH value was measured. The results showed that the pH value of the modified Bayer process red mud was 1.3 units lower than that of the pre-modified Bayer process red mud.

Embodiment 2

[0032] Take 5 g of glucose, 3 g of yeast extract, 20 g of starch and 10 g of calcium dihydrogen phosphate, add 1000 g of distilled water and mix to form an aqueous solution to obtain a liquid modifier. The Bayer process red mud which has been dried, ground and passed through an 18-mesh sieve is mixed with the liquid modifier in a ratio of 1:1 according to w:v, and then allowed to stand at 30°C for 4 days to form a Bayer process red mud solution.

[0033] After drying, the corn stalks crushed and passed through an 18-mesh sieve are added to the Bayer process red mud solution in step 1, and allowed to stand at 30°C for 3 days to obtain an improved Bayer process red mud. The mass ratio of corn stover to Bayer process red mud is 1:13. Then, the modified Bayer process red mud was ground and dried in the shade at room temperature, and the pH value was measured. The results showed that the pH value of the modified Bayer process red mud was lower by 1.7 units than that of the pre-modifie...

Embodiment 3

[0035] Take 10 g of glucose, 3 g of yeast extract, 10 g of starch and 5 g of calcium dihydrogen phosphate, add 1000 g of distilled water and mix to form an aqueous solution to obtain a liquid modifier. The Bayer process red mud, which is dried, ground, and passed through an 18 mesh sieve, is mixed with the liquid modifier in a ratio of 1:1.5 according to w:v, and then allowed to stand at 30° C. for 5 days to form a Bayer process red mud solution.

[0036] The wheat straw, which has been pulverized and passed through an 18-mesh sieve after drying, is added to the Bayer process red mud solution in step 1, and allowed to stand at 30° C. for 2 days to obtain an improved Bayer process red mud. The mass ratio of wheat straw to Bayer process red mud is 1:20. Then, the modified Bayer process red mud was ground and dried in the shade at room temperature, and the pH value was measured. The results showed that the pH value of the modified Bayer process red mud was 1.1 units lower than that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com