Fixed bed gasifier applied to waste gasification, process system and waste gasification method

A fixed-bed gasifier and process system technology, applied in the field of fixed-bed gasifiers, can solve the problems of low processing efficiency, high gas pollutant content, short life of plasma torch, etc., and achieve simple processing, high calorific value, fast The effect of less gray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

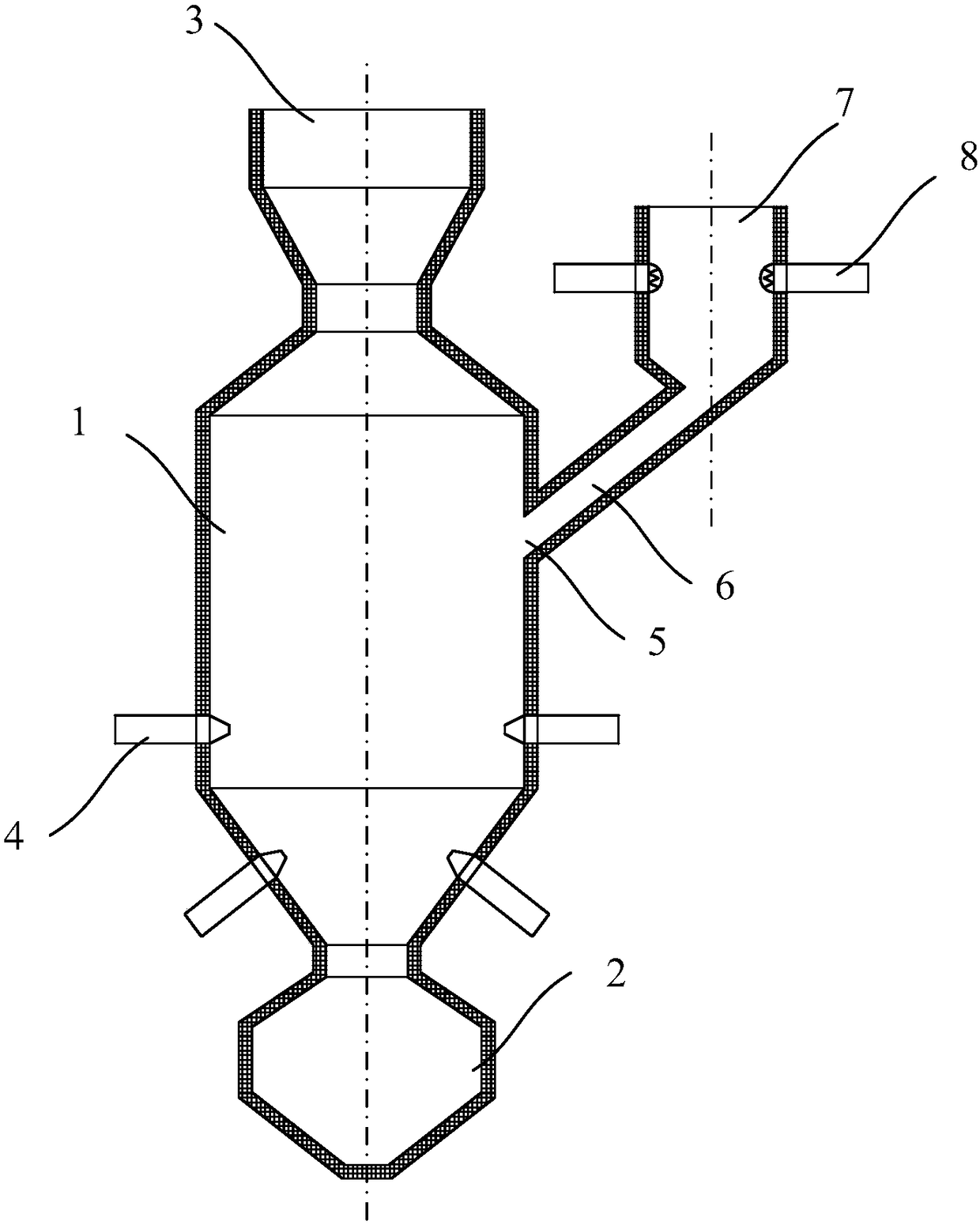

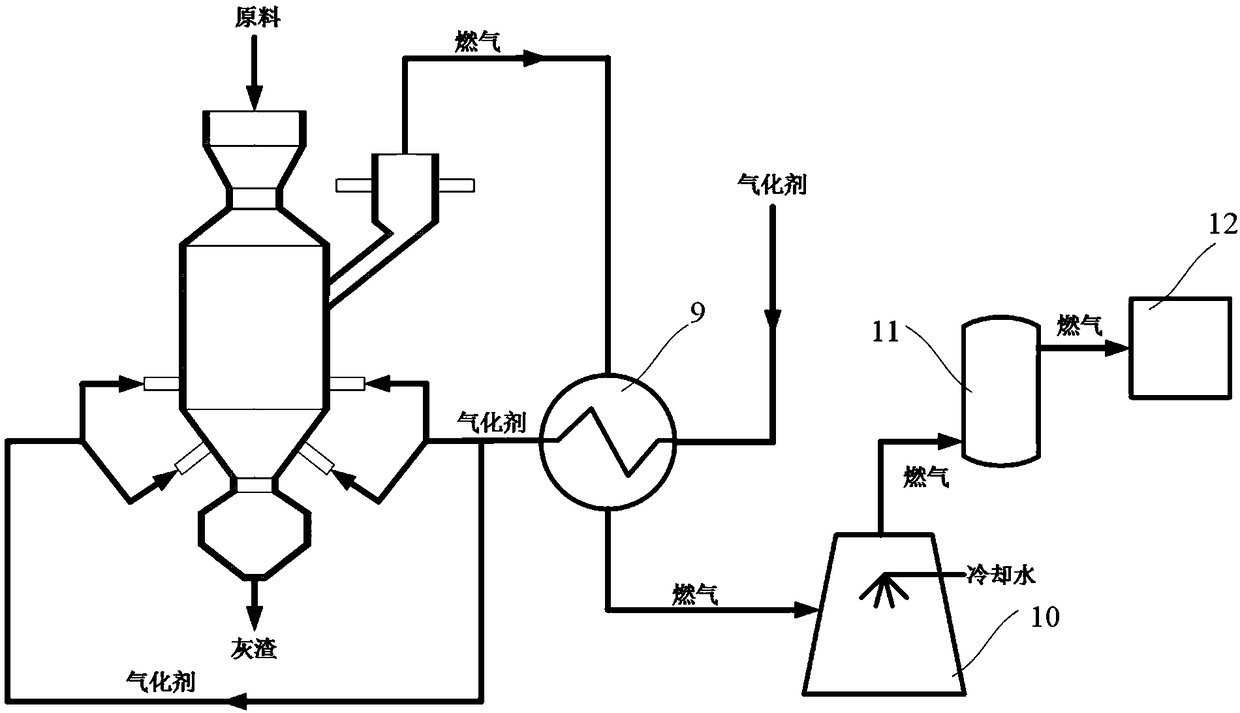

Method used

Image

Examples

Embodiment 1

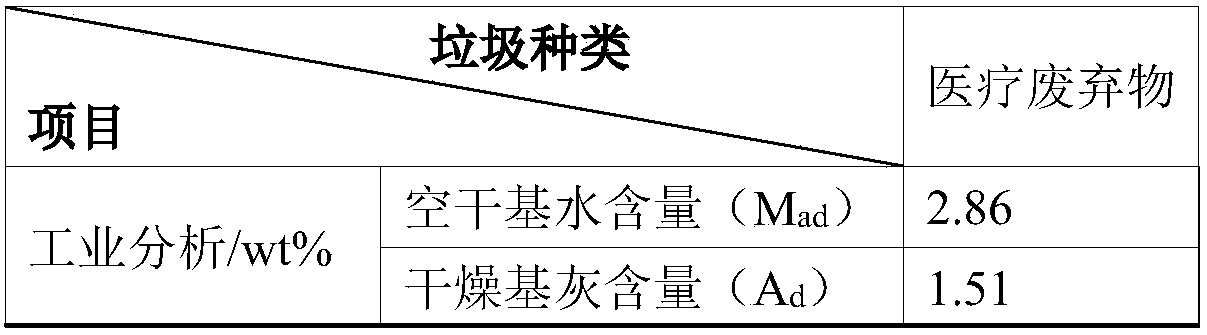

[0062] In this embodiment, the garbage used is medical waste, and its composition analysis is shown in the following table:

[0063] Table 1

[0064]

[0065]

[0066] Taking the daily treatment scale of 100 tons of medical waste as an example, its composition is shown in Table 1, and the dry basis calorific value is about 21.9MJ / kg. The gasification agent is 50% oxygen-rich. The pressure of the gasification reaction is 0.1MPa, the temperature of the gasification reaction is 1100°C, and the ratio of the amount of gasification agent introduced from the furnace bottom to the furnace body is 2:1.

[0067] The outlet synthesis gas temperature is 1000℃, and the gas output is about 5.5t / h, of which CO and H 2 The total content is 42%, there is no tar, SO in the whole process 2 , NOx, dioxins and other pollutants, the carbon content in the ash is less than 3%, the ash is stable in nature, and the pollutants such as heavy metals are below the requirements of the national standard, and there...

Embodiment 2

[0069] In this embodiment, the garbage is sludge, and its composition analysis is shown in the following table:

[0070] Table 2

[0071]

[0072] Taking the daily processing scale of 1,000 tons of sludge as an example, its composition is shown in Table 2, and the dry basis calorific value is about 15.6MJ / kg. The gasification agent is air. The pressure of the gasification reaction is 10MPa, and the temperature of the gasification reaction is 850°C. The ratio of the amount of gasification agent introduced from the furnace bottom to the furnace body is 3:1.

[0073] The outlet synthesis gas temperature is 800℃, and the gas output is about 15t / h, of which CO and H 2 The total content of 20%, there is no tar, SO in the whole process 2 , NOx, dioxins and other pollutants, the carbon content in the ash is less than 5%, the ash is stable, and the pollutants such as heavy metals are lower than the national standard, and there is no risk of leaching.

Embodiment 3

[0075] In this embodiment, the garbage is biomass (water hyacinth), and its component analysis is shown in the following table:

[0076] table 3

[0077]

[0078] Taking the daily processing scale of 100 tons of water hyacinth as an example, its composition is shown in Table 3, and the dry basis calorific value is about 12.7MJ / kg. The gasification agent is 30% oxygen-rich, and 35% coal is added as fuel. The pressure of the gasification reaction is 1MPa, the temperature of the gasification reaction is 1000°C, and the ratio of the amount of gasification agent introduced from the furnace bottom to the furnace body is 2:1.

[0079] The outlet synthesis gas temperature is 950℃, and the gas output is about 6.2t / h, of which CO and H 2 The total content is 36%, there is no tar, SO in the whole process 2 , NOx, dioxins and other pollutants, the carbon content in the ash is less than 3%, the ash is stable in nature, and the pollutants such as heavy metals are below the requirements of the nat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com