Method of preparing NiO-coated lithium titanate composite anode material

A technology for coating lithium titanate and negative electrode materials, applied in the field of negative electrode materials, can solve problems such as complex process steps, and achieve the effects of simple process, fast reaction and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a NiO-coated lithium titanate composite negative electrode material adopts high-temperature solid-phase synthesis, and the steps are: weighing 8 g of potassium carbonate and titanium dioxide according to a certain stoichiometric ratio and placing them in a 300 mL crucible, and then putting Preheat the muffle furnace at room temperature to 800°C at 5°C / min, keep the temperature at 800°C for 4 hours, heat the reaction for 4 hours, take out the crucible directly from the muffle furnace and place it in the air to cool to room temperature to obtain nano titanic acid Lithium, and then adding 2.8% by mass percentage of nano-nickel oxide.

[0026] Wherein, the nano-NiO is prepared by a molten salt combustion method. Nickel acetate is weighed, and the nickel acetate is put into a room temperature muffle furnace with a heating rate of 5° / min. Remove after time and cool at room temperature.

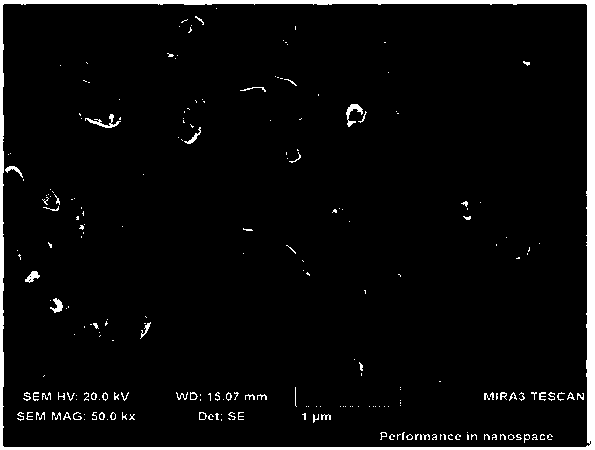

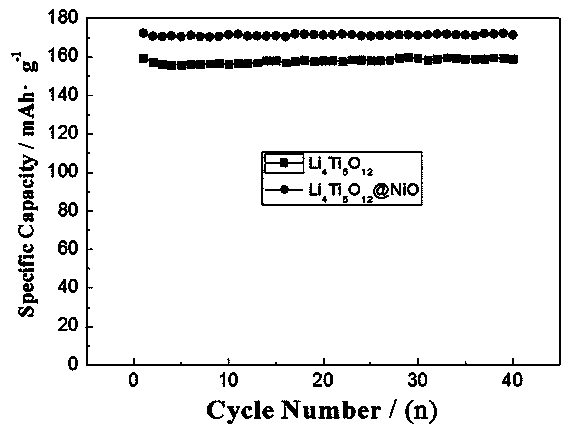

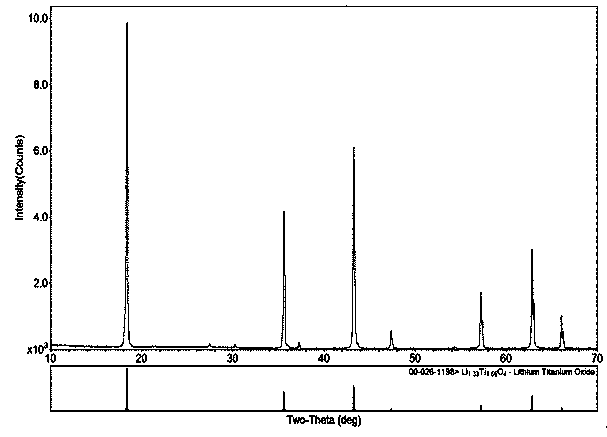

[0027] figure 1 It is the X-ray diffraction pattern of the NiO c...

Embodiment 2

[0031] A method for preparing a NiO-coated lithium titanate composite negative electrode material adopts high-temperature solid-phase synthesis, and the steps are: weighing 7 g of potassium carbonate and titanium dioxide according to a certain stoichiometric ratio and placing them in a 300 mL crucible, and then putting Preheat the muffle furnace at room temperature to 800°C at 5°C / min, keep the temperature at 800°C for 1 hour, heat the reaction for 1 hour, take out the crucible directly from the muffle furnace and place it in the air to cool to room temperature to obtain nano titanic acid Lithium, and then add 0.5% by mass percentage of nano-nickel oxide.

[0032] Wherein, the nano-NiO is prepared by a molten salt combustion method. Nickel acetate is weighed, and the nickel acetate is placed in a muffle furnace at room temperature. The heating rate is 5° / min. Remove after time and cool at room temperature.

[0033] After testing, the NiO-coated lithium titanate composite nega...

Embodiment 3

[0035] A method for preparing a NiO-coated lithium titanate composite negative electrode material adopts high-temperature solid-phase synthesis, and the steps are: weighing 6 g of potassium carbonate and titanium dioxide according to a certain stoichiometric ratio and placing them in a 300 mL crucible, and then putting Preheat the muffle furnace at room temperature to 800°C at 5°C / min, keep the temperature at 800°C for 8 hours, heat the reaction for 8 hours, take out the crucible directly from the muffle furnace and place it in the air to cool to room temperature to obtain nano titanic acid Lithium, and then add 1.2% nano-nickel oxide in mass percentage.

[0036] Wherein, the nano-NiO is prepared by a molten salt combustion method, and nickel acetate is weighed, and the nickel acetate is put into a room temperature muffle furnace, and the heating rate is 5° / min, and the temperature is kept at a predetermined temperature of 700°C for 4 hours; Remove after time and cool at room ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com