Integral high-temperature resistant sealing wave-transparent antenna cover

A high-temperature-resistant, integrated technology, applied to antennas and radiation unit covers on movable objects, can solve problems affecting the performance of radar antennas, poor natural ventilation, poor stiffness of radome, etc., to achieve Good optical transparency and mechanical properties, good aerodynamic performance, and the effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

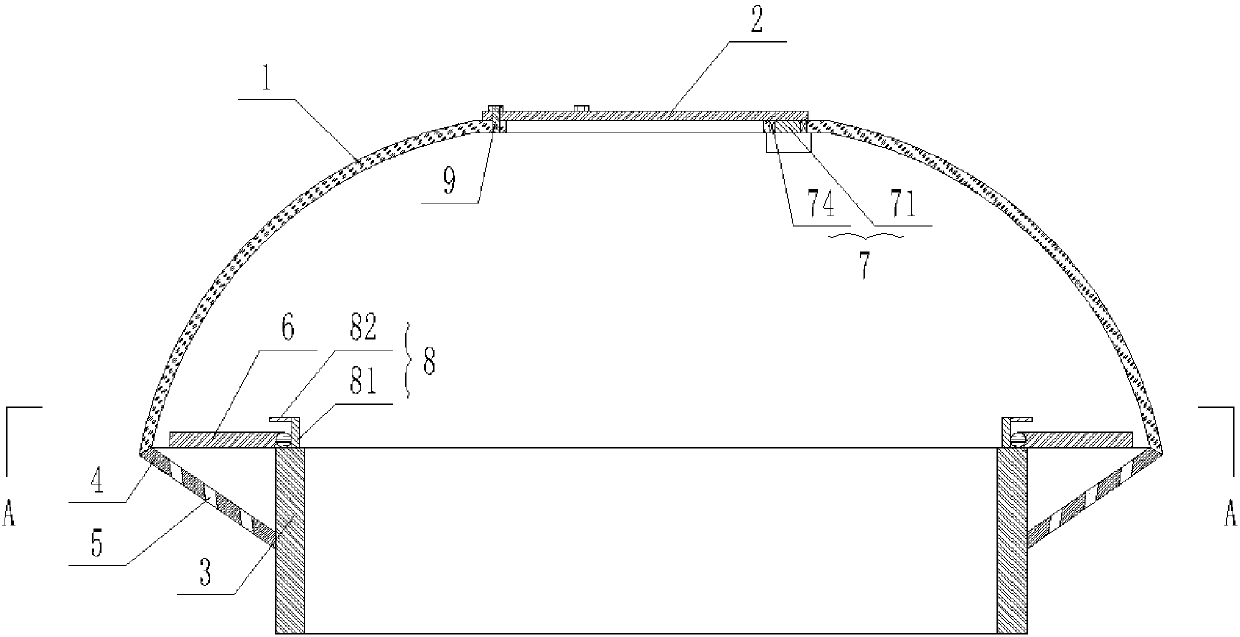

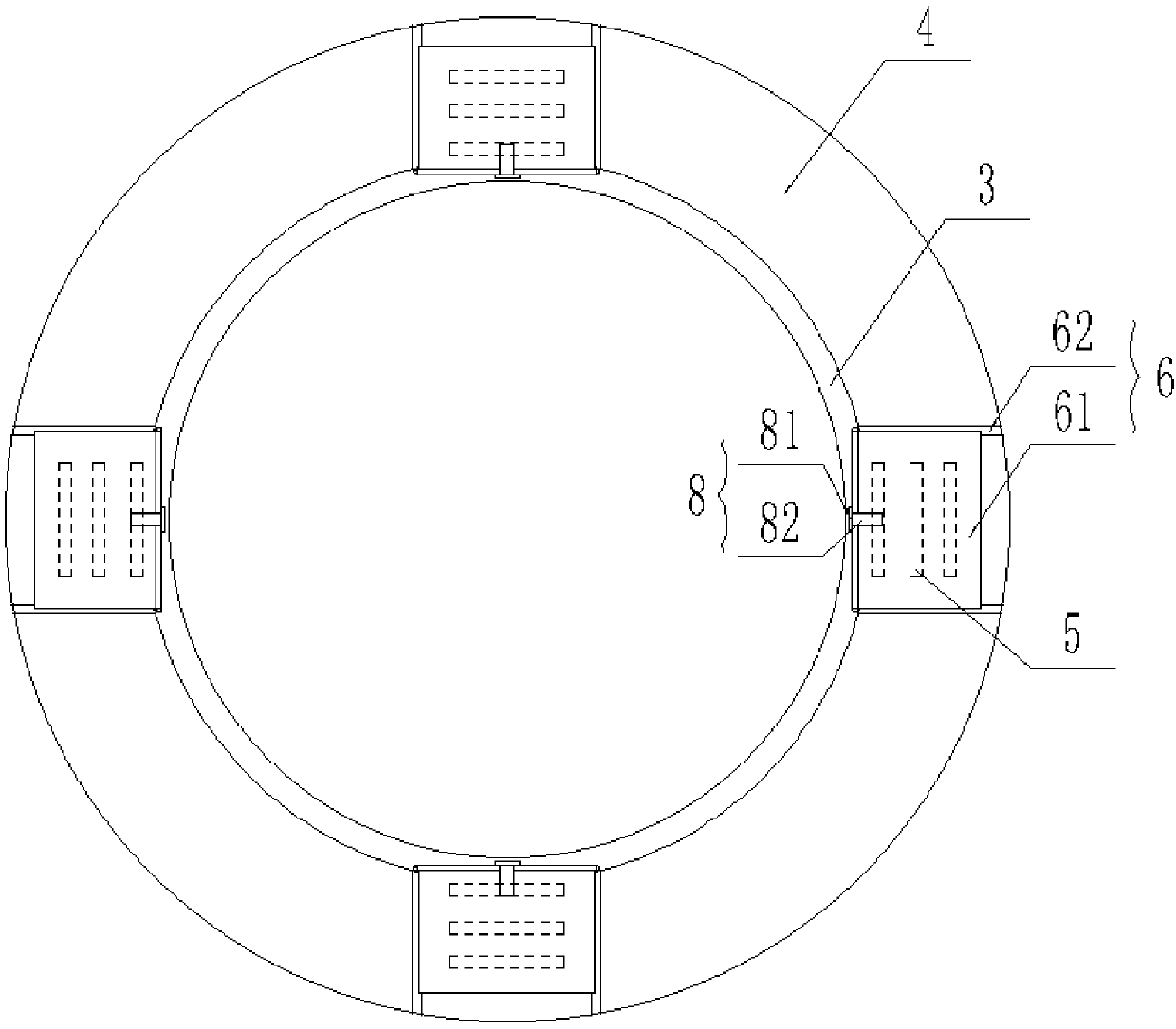

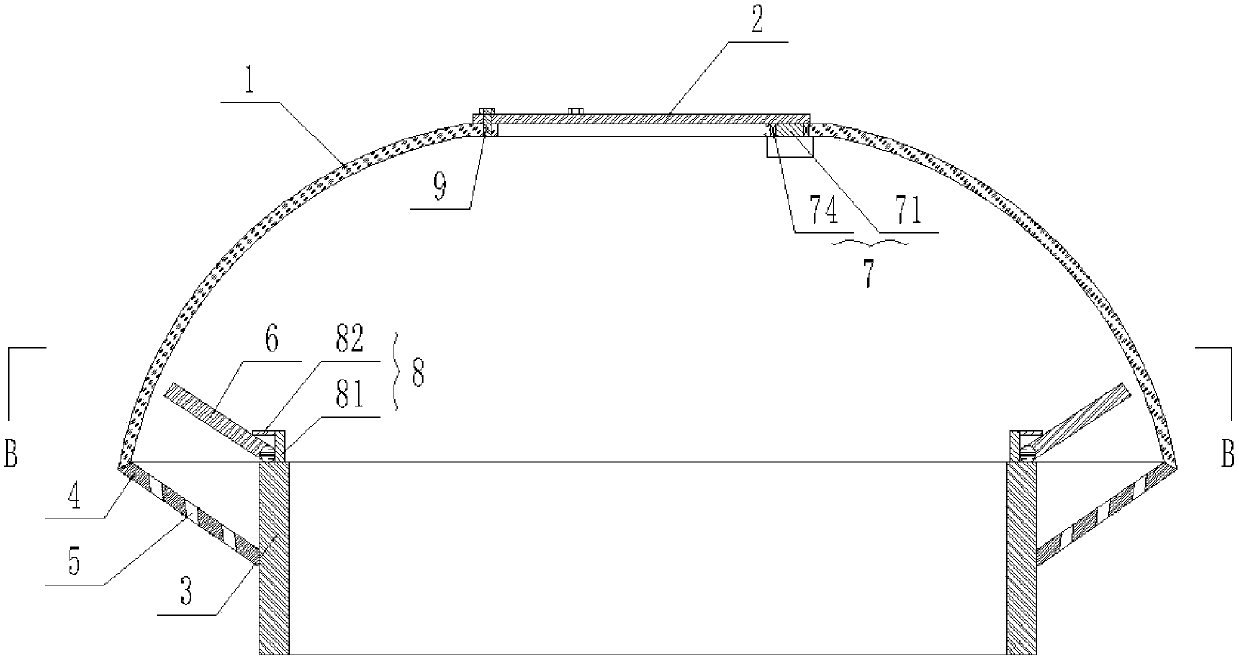

[0028] Such as Figure 1-6 As shown, an integral heat-resistant sealed wave-transparent radome includes a cover body 1, the cover body 1 is a symmetrical structure with a circular arc transition, the top of the cover body 1 is a plane, and the top of the cover body 1 A maintenance opening is provided, and the maintenance opening is covered with a cover plate 2, the maintenance opening and the cover plate 2 are circular, the diameter of the cover plate 2 is greater than the diameter of the maintenance opening, and the cover plate 2 and the cover plate 2 are circular. The center of the maintenance port is located on a different axis, and the connecting cylinder 3 connected with the airborne equipment is vertically provided under the cover body 1, and the lower part of the cover body 1 and the connecting cylinder 3 pass through an annular sloping plate 4 is fixedly connected, the annular sloping plate 4 is provided with a plurality of exhaust hole groups 5, and the connecting cyl...

Embodiment 2

[0039] Such as Figure 1-6 As shown, an integral heat-resistant sealed wave-transparent radome includes a cover body 1, the cover body 1 is a symmetrical structure with a circular arc transition, the top of the cover body 1 is a plane, and the top of the cover body 1 A maintenance opening is provided, and the maintenance opening is covered with a cover plate 2, the maintenance opening and the cover plate 2 are circular, the diameter of the cover plate 2 is greater than the diameter of the maintenance opening, and the cover plate 2 and the cover plate 2 are circular. The center of the maintenance port is located on a different axis, and the connecting cylinder 3 connected with the airborne equipment is vertically provided under the cover body 1, and the lower part of the cover body 1 and the connecting cylinder 3 pass through an annular sloping plate 4 is fixedly connected, the annular sloping plate 4 is provided with a plurality of exhaust hole groups 5, and the connecting cyl...

Embodiment 3

[0050] Such as Figure 1-6 As shown, an integral heat-resistant sealed wave-transparent radome includes a cover body 1, the cover body 1 is a symmetrical structure with a circular arc transition, the top of the cover body 1 is a plane, and the top of the cover body 1 A maintenance opening is provided, and the maintenance opening is covered with a cover plate 2, the maintenance opening and the cover plate 2 are circular, the diameter of the cover plate 2 is greater than the diameter of the maintenance opening, and the cover plate 2 and the cover plate 2 are circular. The center of the maintenance port is located on a different axis, and the connecting cylinder 3 connected with the airborne equipment is vertically provided under the cover body 1, and the lower part of the cover body 1 and the connecting cylinder 3 pass through an annular sloping plate 4 is fixedly connected, the annular sloping plate 4 is provided with a plurality of exhaust hole groups 5, and the connecting cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com