Preparation method of lithium-ion battery cathode material

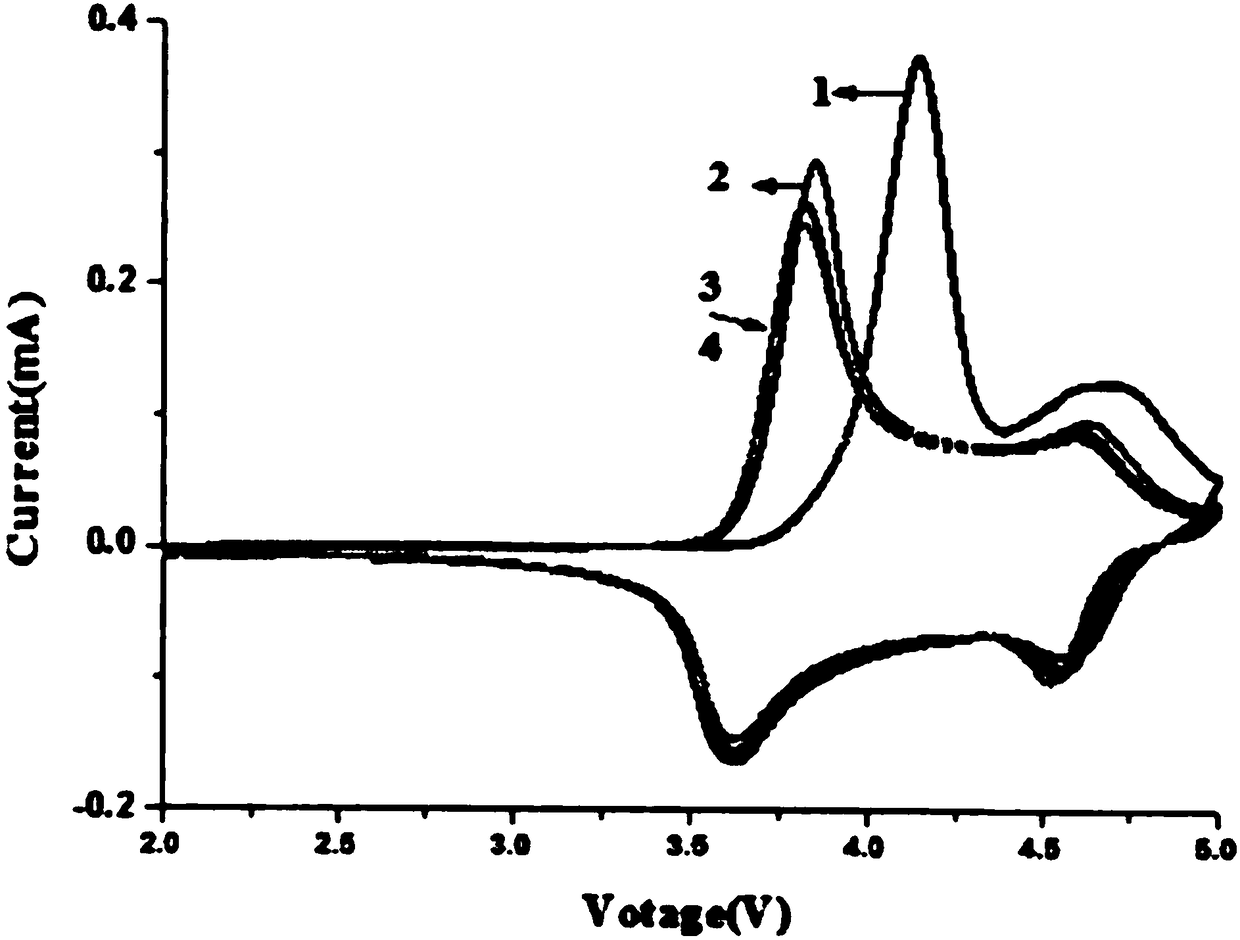

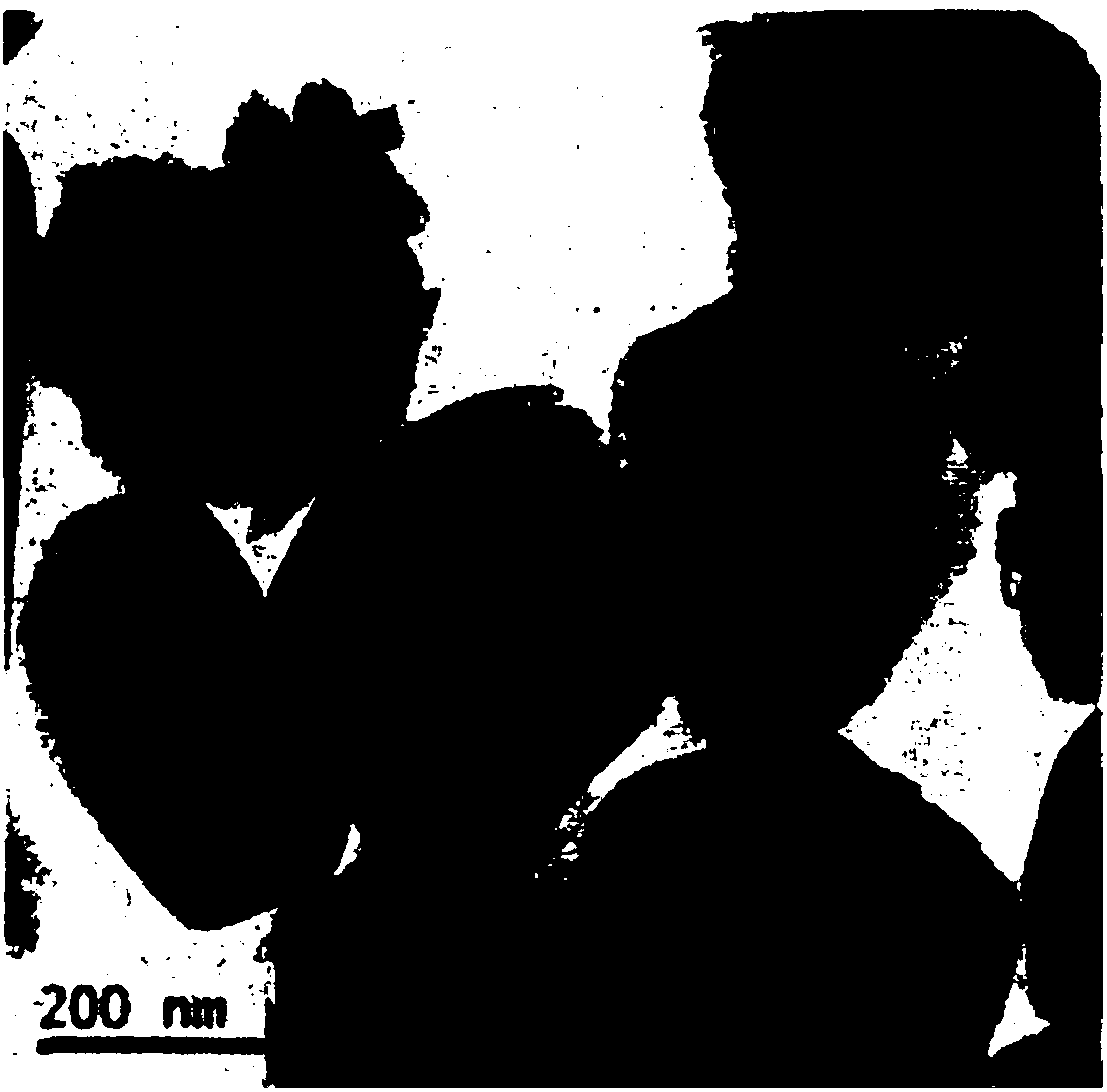

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as long-term grinding and mixing, limited mixing uniformity, batch problems, etc., to improve electrochemical performance, particle size, etc. The effect of uniform size and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A kind of preparation method of lithium-ion battery cathode material, comprises the following steps: the preparation of a, precursor;

[0027] b. High temperature solid phase sintering;

[0028] c. Surface coating.

[0029] Step a is: Weighing equimolar amounts of analytically pure CoAc according to 1:1:1 2 4H 2 O. NiAc 2 4H 2 O, MnAc 2 4H 2 O, under slight heating and stirring, dissolve with deionized water to form solution A; then use (NH 4 ) 2 C 2 o 4 ·H 2 O is used as a precipitating agent, and a little excess of analytically pure (NH 4 ) 2 C 2 o 4 , also dissolved in deionized water under slight heating (30°C) and stirring to form solution B; then use the solution as the base solution, and add solution A to solution B dropwise under high-speed stirring; Afterwards, continue to stir for 0.5 h, and let stand for 3 to 5 h to make the precipitation complete; pour off the supernatant, and put it into a blast drying oven for overnight drying; then add 3 ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com