Preparation method of high-strength carbon-bonded non-metal reinforcing part

A non-metallic reinforcement, high-strength technology, applied in the direction of optical components, optical components, applications, etc., to achieve the effects of non-combustibility, high melting point, and good tensile strain properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

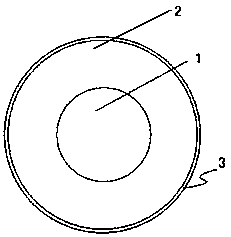

[0028] Such as figure 1 The one shown includes an aramid yarn 1 in the center, a carbon non-metallic bonding layer 2 covering the aramid yarn 1, and an extruded layer 3 covering the carbon non-metallic bonding layer 2 on the outermost layer , the cross-section of the high-strength carbon non-metallic reinforcement is circular; its preparation method includes the steps

[0029] A. Feed: first place the aramid fibers of corresponding specifications on the pay-off frame, bypass the traction, tighten the wire and fix it on the plastic plate;

[0030] B. One-stage heating: heat the aramid fiber, the heating temperature is 95-115°C, and the heating time is 70-85min;

[0031] C. Immersion: Wetting the fibers from multiple spools with an impregnating solution containing: graphite 3.8%, resin 18%, calcium carbonate 6.5%, zinc stearate 8.5%, hydroxide Aluminum 16.2%, sulphate 8.5%, PE powder 9.2%, release agent 12%, resin sizing 17.3%;

[0032] D. Drying / curing: introduce the aramid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com