Preparation method of laser blinding protective lenses

A lens and laser technology, which is applied in the field of preparation of laser blinding protective lenses, can solve problems such as poor sharp cutoff, narrow absorption bandwidth, and darkened field of view, and achieve small indirect band gap, increased absorption coefficient, and polarizability increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

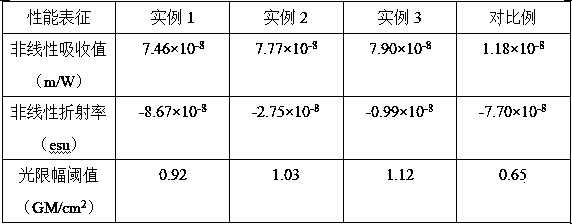

Examples

example 1

[0024] Take 10g of molybdenum disulfide and 3.0g of sodium cholate, add it into 2L of deionized water, and disperse it with a 500W ultrasonic wave for 6 hours under a constant temperature water bath at 40°C to obtain a molybdenum disulfide dispersion, and put the molybdenum disulfide dispersion into a centrifuge , centrifuged at 3000r / min for 20min, collected the supernatant, then centrifuged at 12000r / min for 30min, collected the precipitate to obtain molybdenum disulfide nanosheets, added molybdenum disulfide nanosheets to 500mL of absolute ethanol, Ultrasonic cleaning with 300W ultrasonic wave for 20min, centrifugation at 12000r / min for 30min, collecting the precipitate, placing the precipitate in a drying oven, and drying at 105°C for 3h to obtain pretreated molybdenum disulfide nanosheets. Take 2g of cadmium oxide, 0.4 1g zinc oxide, 10g oleic acid, 10g octadecene were put into the flask, heated to 220°C under nitrogen atmosphere, stirred at 200r / min for 20min, cooled to 1...

example 2

[0026]Take 13g of molybdenum disulfide and 3.7g of sodium cholate, add it to 2.5L of deionized water, and disperse it in a 500W ultrasonic wave for 7 hours under a constant temperature water bath at 45°C to obtain a molybdenum disulfide dispersion. Put the molybdenum disulfide dispersion into a centrifuge centrifuge at 3500r / min for 25min, collect the supernatant, then centrifuge the supernatant at 12250r / min for 35min, collect the precipitate to obtain molybdenum disulfide nanosheets, add molybdenum disulfide nanosheets to 550mL absolute ethanol , cleaned with 300W ultrasonic wave for 25min, then centrifuged at 12250r / min for 35min, collected the precipitate, put the precipitate in a drying oven, and dried at 107°C for 4h to obtain pretreated molybdenum disulfide nanosheets. Take 2.5g of cadmium oxide , 0.5g of zinc oxide, 13g of oleic acid, and 13g of octadecene were put into a flask, heated to 230°C under a nitrogen atmosphere, stirred at 250r / min for 25min, and cooled to 15...

example 3

[0028] Take 15g of molybdenum disulfide and 4.5g of sodium cholate, add it into 3L of deionized water, and disperse it with a 500W ultrasonic wave for 8 hours under a constant temperature water bath at 50°C to obtain a molybdenum disulfide dispersion, and put the molybdenum disulfide dispersion into a centrifuge , centrifuged at 4000r / min for 30min, collected the supernatant, then centrifuged at 12500r / min for 40min, collected the precipitate to obtain molybdenum disulfide nanosheets, added molybdenum disulfide nanosheets into 600mL absolute ethanol, Ultrasonic cleaning with 300W ultrasonic wave for 30min, centrifugation at 12500r / min for 40min, collecting the precipitate, placing the precipitate in a drying oven, and drying at 110°C for 5h to obtain pretreated molybdenum disulfide nanosheets. Take 3g of cadmium oxide, 0.6 g zinc oxide, 15g oleic acid, and 15g octadecene were put into a flask, heated to 240°C under a nitrogen atmosphere, stirred at 300r / min for 30min, and coole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com