Pretreatment method of molasses alcohol wastewater

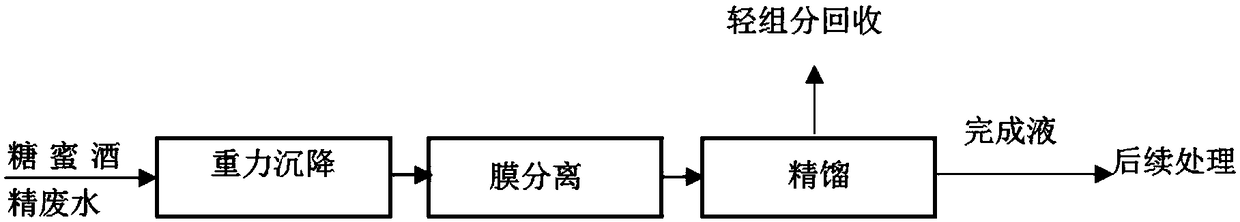

A technology for the pretreatment of molasses alcohol wastewater, which is applied in the fields of food industry wastewater treatment, water/sewage treatment, natural water treatment, etc., can solve the problems affecting the practical effect of the concentration combustion method, and achieve the improvement of fluid mechanics and heat transfer characteristics, and reduce the load, and the effect of ensuring up-to-standard discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

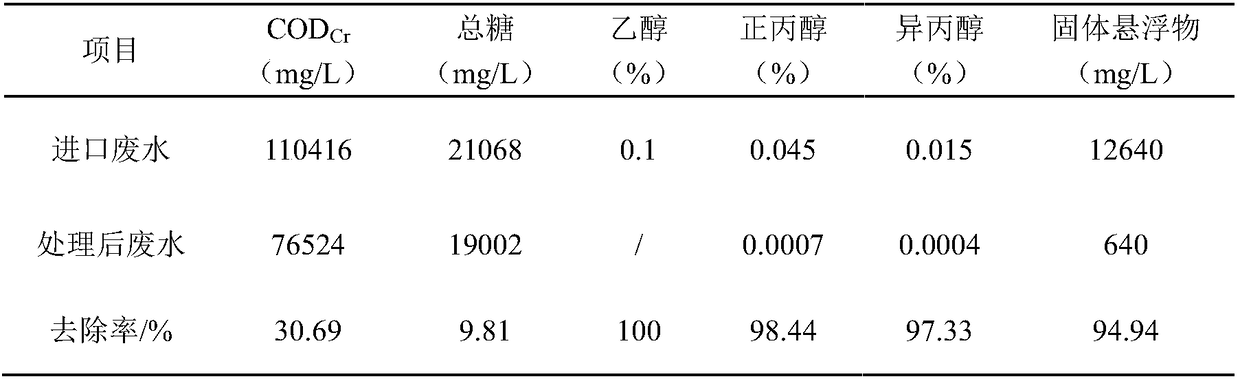

[0039] In this embodiment, a pretreatment method for molasses alcohol wastewater is provided. The pretreatment object in this embodiment is taken from the molasses alcohol wastewater produced by domestic alcohol production plants using molasses as raw material to produce alcohol. The main water quality indicators are: pH4.2, COD Cr 110416mg / L, total sugar content 21068mg / L, ethanol content 0.1%, n-propanol content 0.045%, isopropanol content 0.015%, solid suspended matter content 12640mg / L.

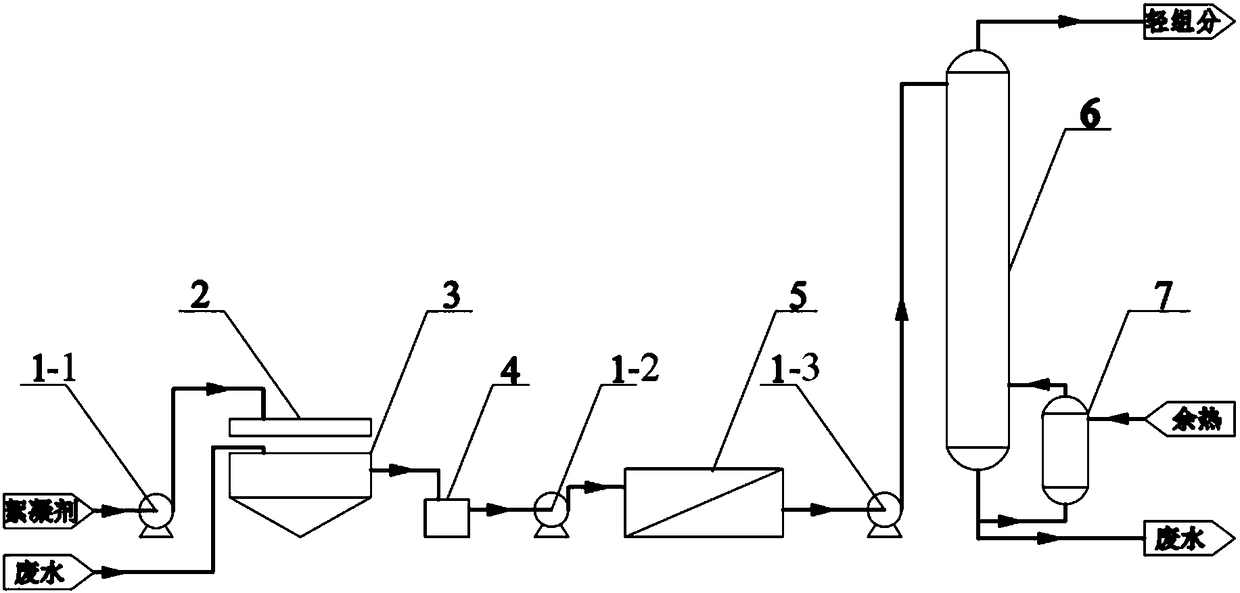

[0040] Including the following process steps:

[0041] (1) The molasses alcohol wastewater enters the gravity settling tank and is treated with the flocculant fed by the metering pump for flocculation and sedimentation. The amount of flocculant polyacrylamide added by metering pump is 2g / m 3 The waste water and flocculant are put into the circular gravity settling tank through the concentric circle distributor. The bottom of the gravity sedimentation tank is a cone, which is convenien...

Embodiment 2

[0047] In this embodiment, a pretreatment method for molasses alcohol wastewater is provided. The pretreatment object in this embodiment is the molasses alcohol wastewater produced by domestic alcohol production plants using molasses as raw material to produce alcohol. The wastewater is brown-black liquid, and the water quality indicators are: pH4.2, COD Cr 111024mg / L, total sugar content 21214mg / L, ethanol content 0.11%, n-propanol content 0.043%, isopropanol content 0.015%, solid suspended matter content 12742mg / L. Including the following process steps:

[0048] (1) The molasses alcohol wastewater enters the gravity settling tank and is treated with the flocculant fed by the metering pump for flocculation and sedimentation. The amount of flocculant polyacrylamide added by the metering pump is 2.3g / m 3 The waste water and flocculant are put into the circular gravity settling tank through the concentric circle distributor. The bottom of the gravity sedimentation tank is a...

Embodiment 3

[0054] In this embodiment, a pretreatment method for molasses alcohol wastewater is provided. The pretreatment object in this embodiment is taken from the molasses alcohol wastewater produced by the domestic alcohol production plant using molasses as raw material to produce alcohol. The main water quality indicators are: pH 4.1, COD Cr 108962mg / L, total sugar content 20536mg / L, ethanol content 0.1%, n-propanol content 0.042%, isopropanol content 0.014%, solid suspended matter content 11657mg / L.

[0055] Including the following process steps:

[0056] (1) The molasses alcohol wastewater enters the gravity settling tank and is treated with the flocculant fed by the metering pump for flocculation and sedimentation. The amount of flocculant polyacrylamide added by metering pump is 3g / m 3 The waste water and flocculant are put into the circular gravity settling tank through the concentric circle distributor. The bottom of the gravity sedimentation tank is a cone, which is conve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com