Lignin grafted polycarboxylate with high carboxyl content and its preparation method and application

A branch polycarboxylate and lignin technology, which is applied in the field of lignin grafted polycarboxylate with high carboxyl content and its preparation, can solve the problem of difficult preparation of lignin carboxylate with high carboxyl content and the influence of lignin carboxylic acid Solve problems such as salt use performance and low solubility, achieve good steric hindrance, good dispersion performance, and improve dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

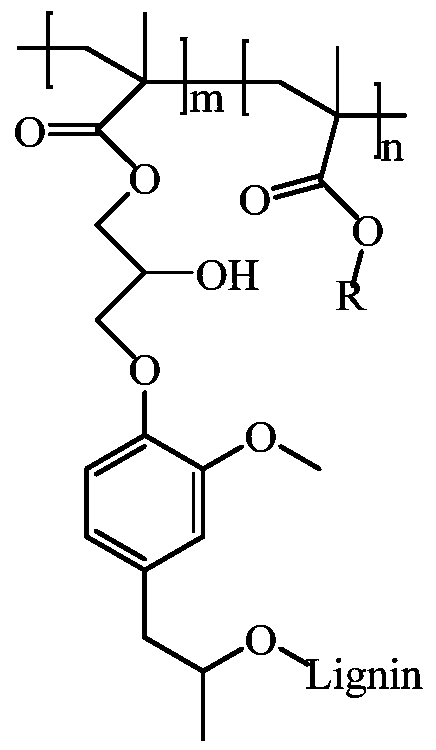

[0038] Mix 10g of glycidyl acrylate, 30g of acrylic acid, 20g of methyl methacrylate and 100g of deionized water evenly, and heat up to 50°C; dissolve 0.5g of ammonium persulfate in 20g of deionized water, and then drop them in 0.5 hours. Then, it was reacted at 50°C for 0.5 hours. Dissolve 100g of sulfonated alkali lignin in 200g of deionized water, then add it to the above reaction solution, raise the temperature to 60°C, keep the temperature for 3 hours, and finish the reaction, adjust the pH of the product to neutral with 30% sodium hydroxide solution, that is To obtain lignin grafted polycarboxylate.

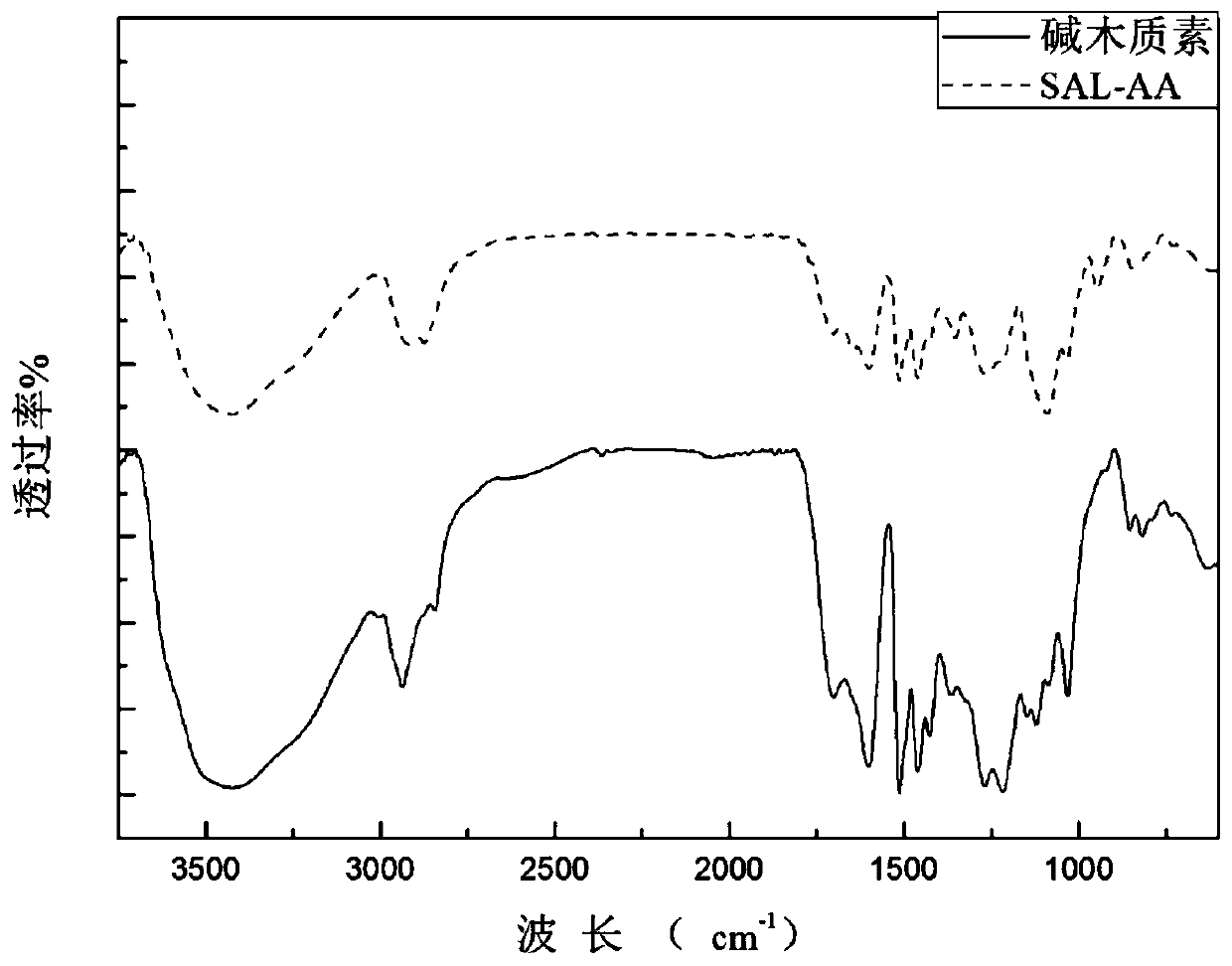

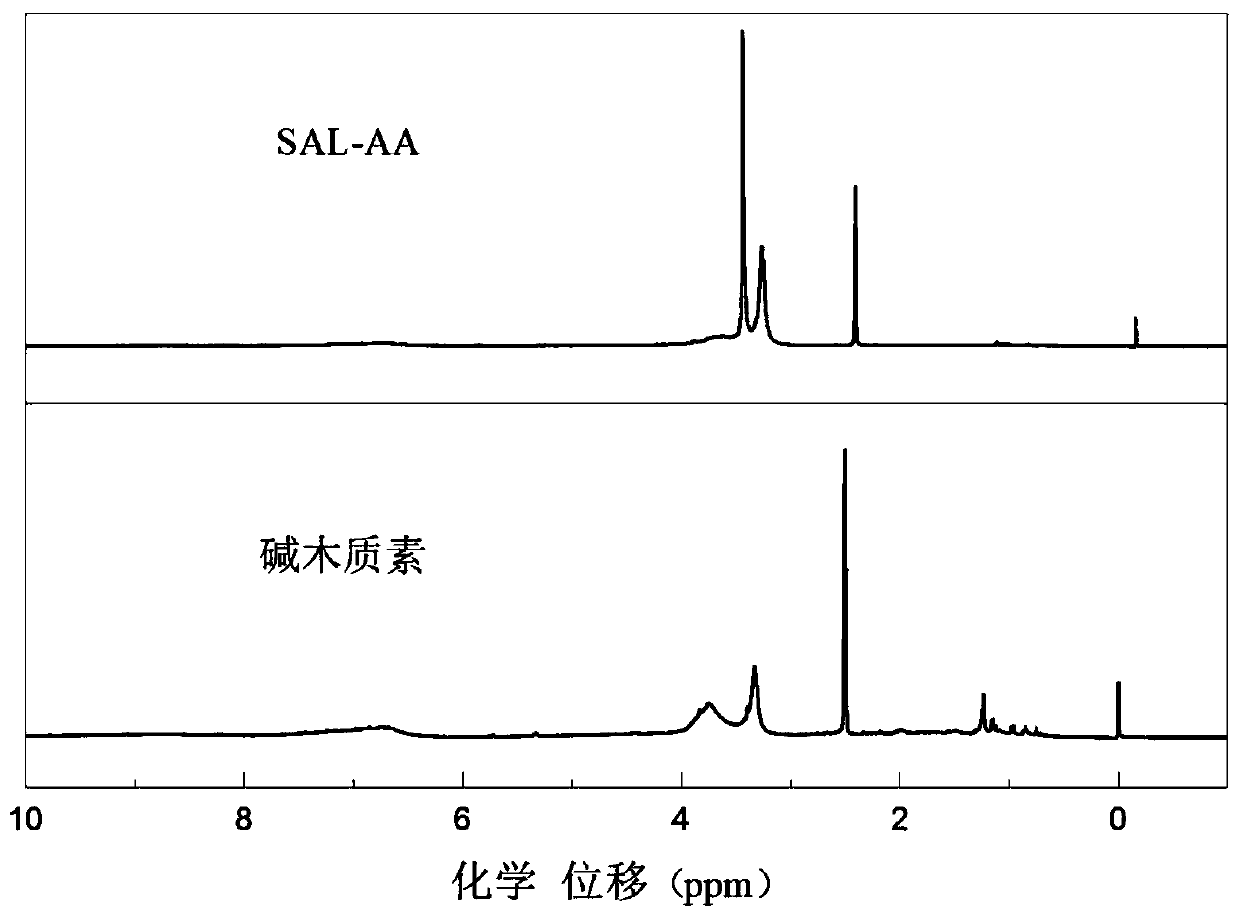

[0039] Purify the product of Example 1, add hydrochloric acid to the lignin-grafted polycarboxylate reaction solution obtained after the reaction to adjust pH=2, stir for 15 minutes and then centrifuge to remove the supernatant, take the precipitate and add a certain amount of deionized water, Adjust the pH to 7, filter to remove insoluble matter, and dialyze the remaining...

Embodiment 2

[0045] Mix 16g of glycidyl methacrylate and 5g of allyl glycidyl ether, 32g of crotonic acid, 25g of butyl acrylate and 120g of deionized water, and heat up to 60°C; dissolve 1g of potassium persulfate in 26g of deionized water , and then the dropwise addition was completed in 0.5 hours, and then reacted at 60° C. for 1 hour. Dissolve 100g of sulfonated alkali lignin in 230g of deionized water, then add it to the above reaction solution, raise the temperature to 80°C, keep it warm for 1 hour, and finish the reaction. Use 30% sodium hydroxide solution to adjust the pH of the product to neutral, that is To obtain lignin grafted polycarboxylate.

[0046] Can be tested according to the same test method of embodiment 1, the polycarboxylic acid monomer of the product obtained in this embodiment 2 is connected with lignin by an ether bond, wherein m=2~3, n=30~40, R=-H or -C 4 h 9 . The carboxylic acid group content of the product obtained in Example 2 is 2.8-3.2 mmol / g, and the w...

Embodiment 3

[0048] Mix 20g of methallyl glycidyl ether, 36g of maleic acid, 40g of ethyl acrylate and 150g of deionized water, and heat up to 70°C; dissolve 1.5g of benzoyl peroxide in 40g of deionized water, and then The dropwise addition was completed in 1 hour, and then reacted at 70° C. for 1 hour. Dissolve 100g of sodium lignosulfonate in 300g of deionized water, then add it to the above reaction solution, raise the temperature to 90°C, and keep the temperature for 1.5 hours to complete the reaction. Use 30% sodium hydroxide solution to adjust the pH of the product to neutral, that is To obtain lignin grafted polycarboxylate.

[0049] Can be tested according to the same testing method of embodiment 1, the polycarboxylic acid monomer of the product obtained in this embodiment 3 is connected with lignin by an ether bond, wherein m=2~3, n=20~30, R=-H or -C 2 h 5 . The carboxylic acid group content of the product obtained in Example 3 is 2.5-2.9 mmol / g, and the weight-average molecul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com