Epoxidized modified methylphenyl silicone resin for LED (Light Emitting Diode) packaging adhesive and preparation method thereof

A methyl phenyl silicon, LED packaging technology, applied in adhesives, electrical components, circuits, etc., can solve the problems of low light transmittance, low refractive index, poor compatibility of epoxy resin, and achieve simple and easy preparation process operation. Control, low impurity content, high cohesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

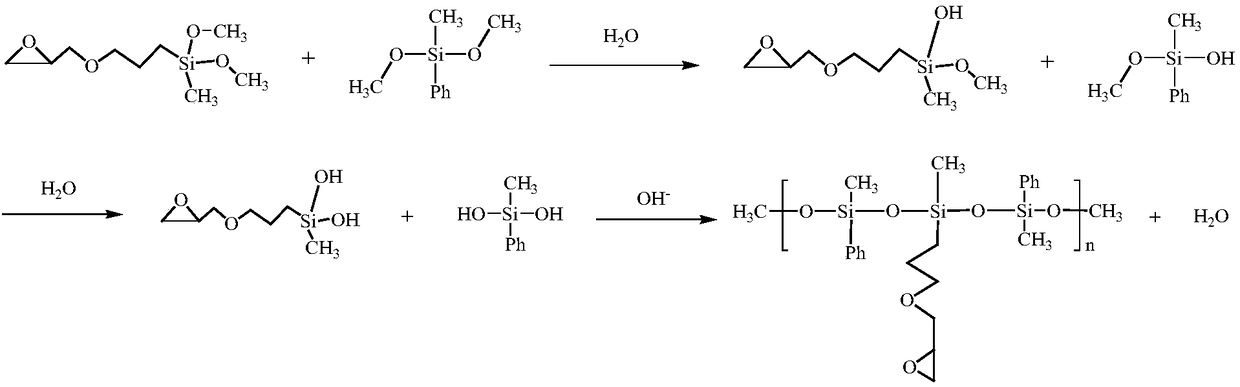

[0028] Preparation of epoxidized modified methylphenyl silicone resin:

[0029] (1) Preparation of Epoxidized Modified Methylphenyl Silicone Resin Crude Product

[0030] 22g of 3-glycidyl etheroxypropylmethyldimethoxysilane and 54.7g of methylphenyldimethoxysilane were mixed in a beaker and stirred evenly, and poured into a constant pressure dropping funnel as reactants. Take 76.7g of distilled water and 1.68g of barium hydroxide monohydrate and place them in a 250ml four-necked flask to prepare a mixture, stir and heat the mixture, and start to add the reactants dropwise when the temperature rises to 60°C, and control the reaction temperature to be 85°C. After the reactants were dropped, they were reacted at 85° C. for 4 h, and then the catalyst was removed by suction filtration under reduced pressure to obtain a crude product of epoxidized modified methylphenyl silicone resin.

[0031] (2) Refined epoxidized modified methylphenyl silicone resin

[0032] Wash the crude prod...

Embodiment 2

[0034] Preparation of epoxidized modified methylphenyl silicone resin:

[0035] (1) Preparation of Epoxidized Modified Methylphenyl Silicone Resin Crude Product

[0036] 22g of 3-glycidyl etheroxypropylmethyldimethoxysilane and 54.7g of methylphenyldimethoxysilane were mixed in a beaker and stirred evenly, and poured into a constant pressure dropping funnel as reactants. Take 86.4g of distilled water and 1.68g of barium hydroxide monohydrate and place them in a 250ml four-necked flask to prepare a mixture. Stir and heat the mixture. When the temperature rises to 60°C, start to add the reactants dropwise, and control the reaction temperature to 70°C. After the reactants were dropped, they were reacted at 70° C. for 4 h, and then the catalyst was removed by suction filtration under reduced pressure to obtain a crude product of epoxidized modified methylphenyl silicone resin.

[0037] (2) Refined epoxidized modified methylphenyl silicone resin

[0038] Wash the crude product of...

Embodiment 3

[0040] Preparation of epoxidized modified methylphenyl silicone resin:

[0041] (1) Preparation of Epoxidized Modified Methylphenyl Silicone Resin Crude Product

[0042] 22g of 3-glycidyl etheroxypropylmethyldimethoxysilane and 54.7g of methylphenyldimethoxysilane were mixed in a beaker and stirred evenly, and poured into a constant pressure dropping funnel as reactants. Take 86.4g of distilled water and 3.36g of barium hydroxide monohydrate and place them in a 250ml four-neck flask to prepare a mixture. Stir and heat the mixture. When the temperature rises to 60°C, start to add the reactants dropwise, and control the reaction temperature to 85°C. After the reactants were dropped, they were reacted at 85° C. for 4 h, and then the catalyst was removed by suction filtration under reduced pressure to obtain a crude product of epoxidized modified methylphenyl silicone resin.

[0043](2) Refined epoxidized modified methylphenyl silicone resin

[0044] Wash the crude product of ep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com