Medical freeze-dried sterile polyethylene film and preparation method thereof

A polyethylene film and polyethylene resin technology, which is applied in the field of pharmaceutical freeze-dried sterile polyethylene film and its preparation, can solve the problems of cross-contamination of drugs, difficult cleaning, and difficult detection of drug residues, and achieve strong mechanical properties, The effect of low insoluble particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

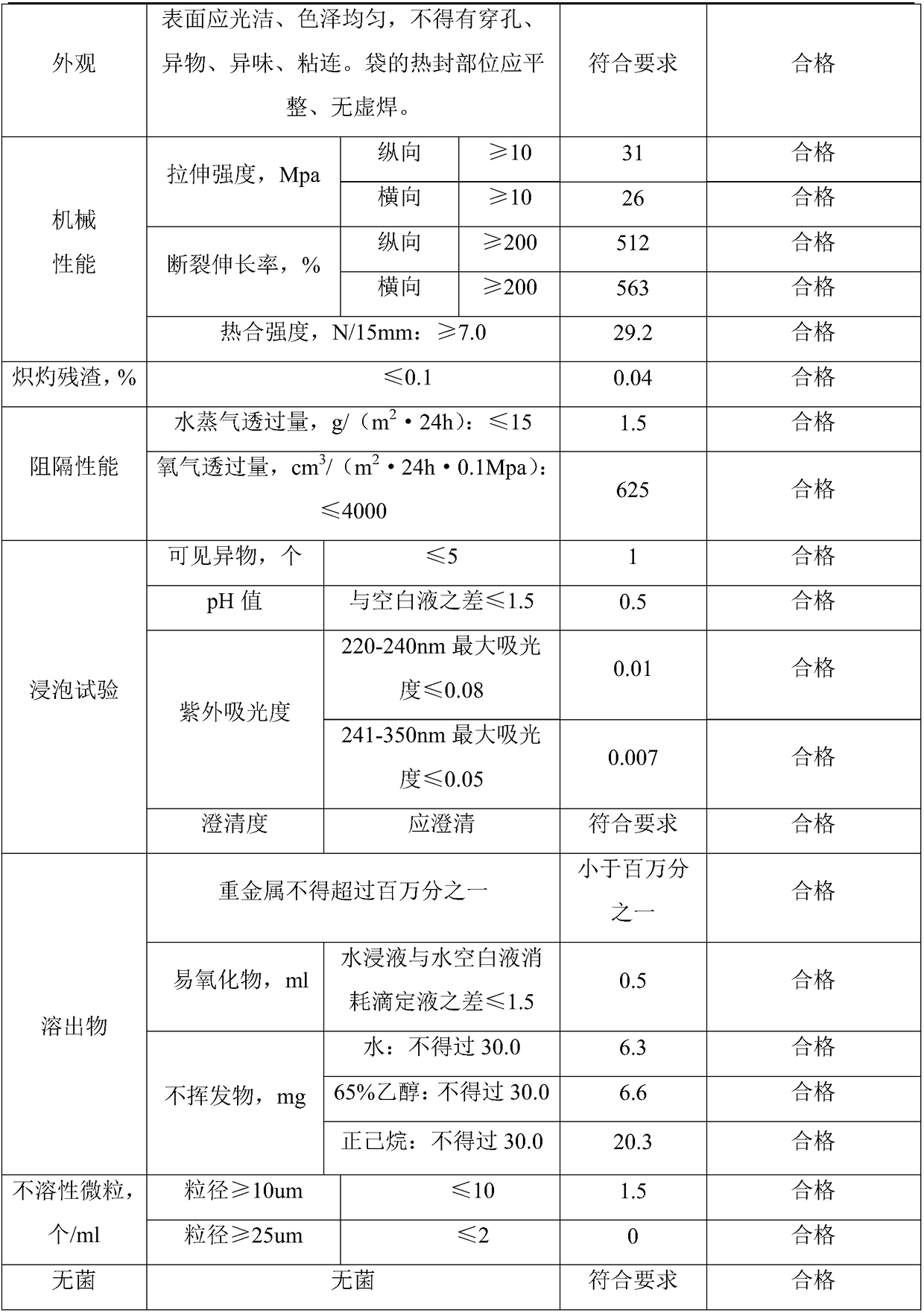

Embodiment 1

[0038] (1) Formula composition: 8 parts by weight of ultra-high molecular weight polyethylene resin with a melt index of 0.3 g / 10 min, and 2 parts by weight of metallocene polyethylene with a melt index of 0.3 g / 10 min.

[0039] (2) Mixing: Add the polyethylene resin of the above components into a mixer or blender, and mix for 15 minutes.

[0040] (3) Film making: Melt and blend uniformly mixed polyethylene resin through a film blowing machine. The temperature of the film blowing machine is controlled at 230°C, and extrusion blow molding is performed.

[0041] (4) Cutting film: Cut the roll film formed by extrusion blow molding according to the specification and size required by the customer.

[0042] (5) Packaging: The cut and formed polyethylene film is packed in more than two layers of pharmaceutical low-density polyethylene bags, and then packed in cartons or woven bags.

[0043] (6) Sterilization: use Co 60 γ-ray sterilization, the sterilization dose is 30KGy.

[0044]...

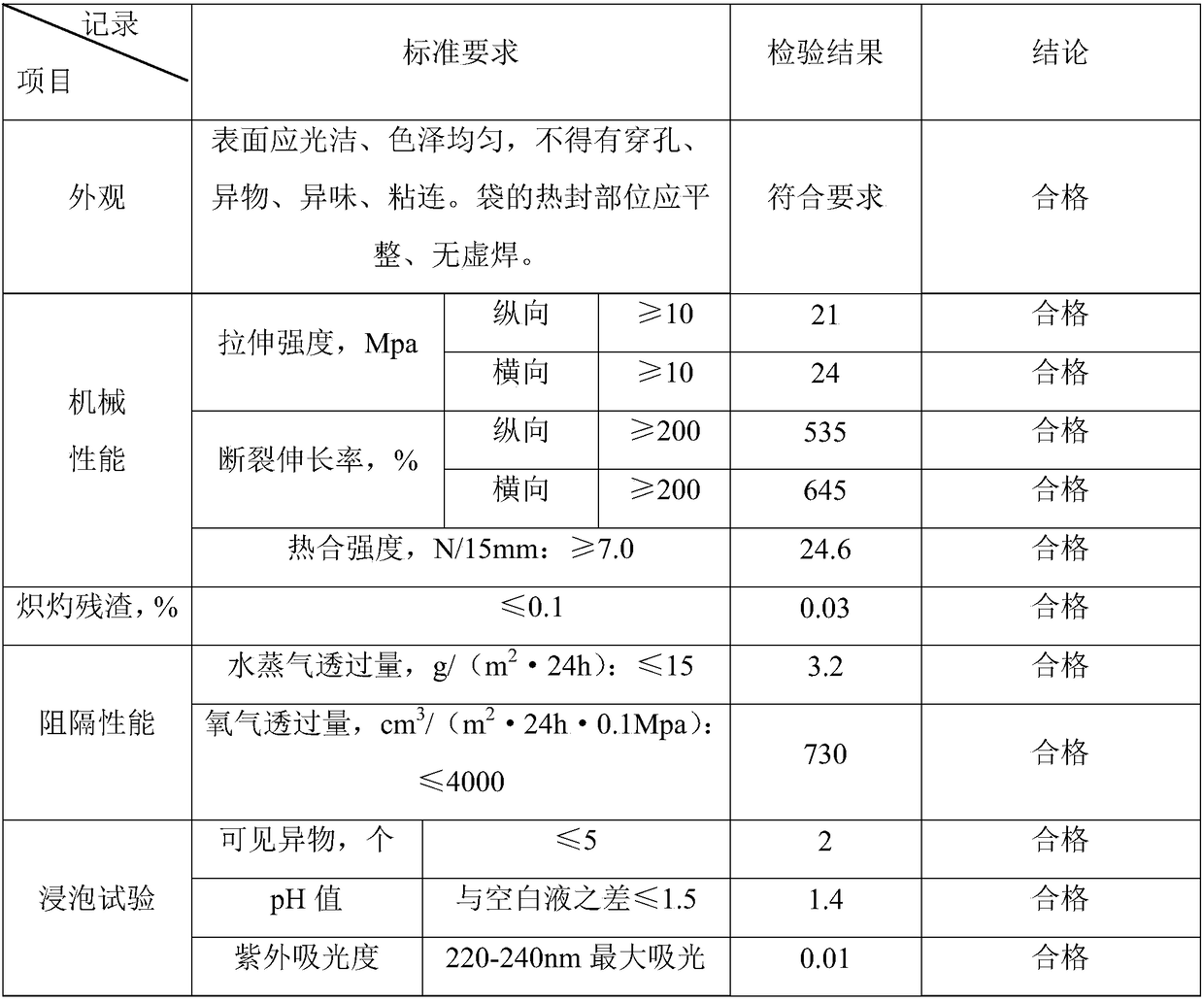

Embodiment 2

[0049] (1) Formula composition: 6 parts by weight of ultra-high molecular weight polyethylene resin with a melt index of 0.3 g / 10 min, and 4 parts by weight of metallocene polyethylene with a melt index of 0.3 g / 10 min.

[0050] (2) Mixing: Add the polyethylene resin of the above components into a mixer or blender, and mix for 15 minutes.

[0051] (3) Film making: Melt and blend uniformly mixed polyethylene resin through a film blowing machine. The temperature of the film blowing machine is controlled at 210° C., and extrusion blow molding is performed.

[0052] (4) Cutting film: Cut the roll film formed by extrusion blow molding according to the specification and size required by the customer.

[0053] (5) Packaging: The cut and formed polyethylene film is packed in more than two layers of pharmaceutical low-density polyethylene bags, and then packed in cartons or woven bags.

[0054] (6) Sterilization: use Co 60 Gamma-ray sterilization, the sterilization dose is 28KGy.

...

Embodiment 3

[0060] (1) Formula composition: 6 parts by weight of ultra-high molecular weight polyethylene resin with a melt index of 0.3g / 10min, 2 parts by weight of metallocene polyethylene with a melt index of 0.3g / 10min, and linear polyethylene resin with a melt index of 1.0g / 10min. 2 parts by weight of vinyl resin.

[0061] (2) Mixing: Add the polyethylene resin of the above components into a mixer or blender, and mix for 30 minutes.

[0062] (3) Film making: Melt and blend the homogeneously mixed polyethylene resin through a film blowing machine. The temperature of the film blowing machine is controlled at 190°C, and extrusion blow molding is performed.

[0063] (4) Cutting film: Cut the roll film formed by extrusion blow molding according to the specification and size required by the customer.

[0064] (5) Packaging: The cut and formed polyethylene film is packed in more than two layers of pharmaceutical low-density polyethylene bags, and then packed in cartons or woven bags.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com