Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of low mobility, electron and hole recombination, etc., and achieve the effects of easy synthesis, simple operation, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

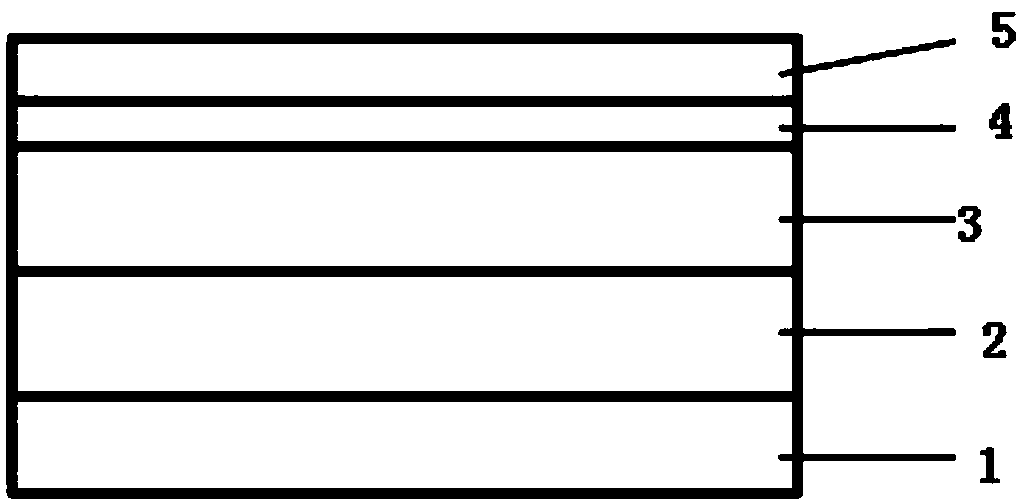

[0035] A method for preparing a perovskite solar cell, comprising the steps of:

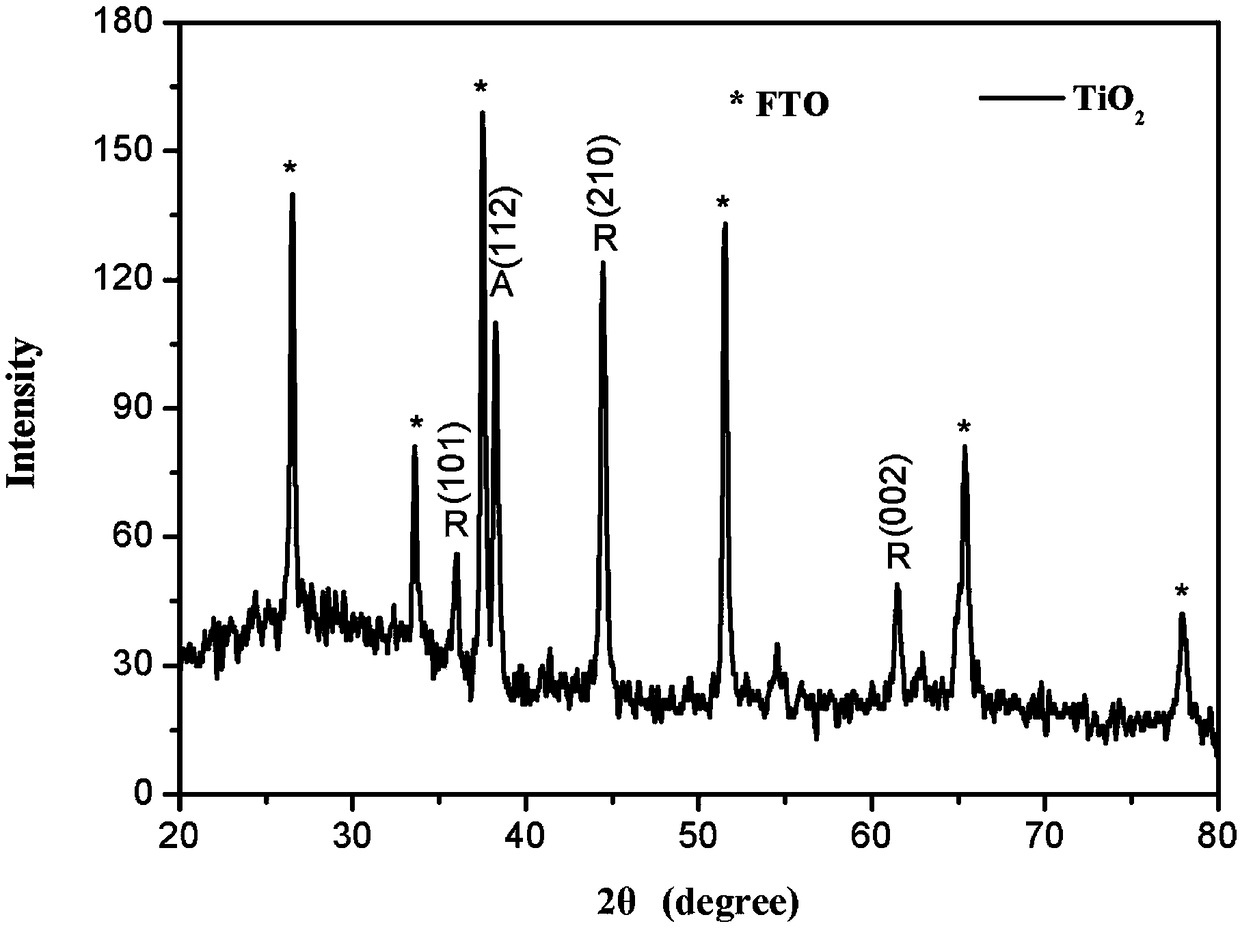

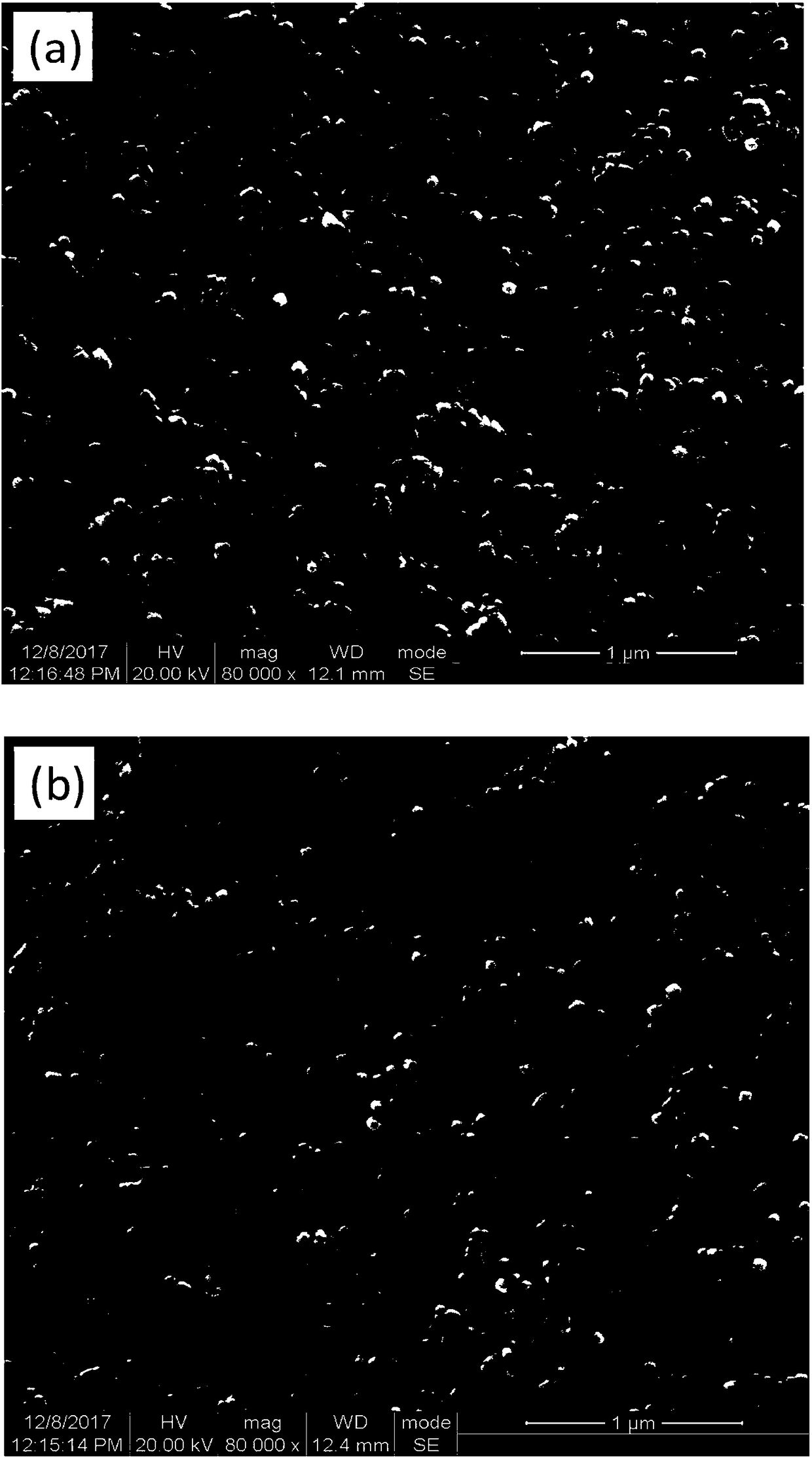

[0036] Step S1, select FTO (tin oxide doped with F) conductive glass with a surface roughness of less than 1 nm as the conductive substrate, first clean the FTO conductive substrate, dry it with dry nitrogen after cleaning, and perform ultraviolet light and ozone treatment , to obtain a clean FTO conductive substrate; prepare TiO on the clean FTO conductive substrate 2 Dense layer film, the film thickness is 60nm, the specific operation method is: prepare a certain concentration (0.25mol / L) titanium isopropoxide ethanol solution, use spin coating method or spray coating method or roller coating method or spray pyrolysis method or LB film TiO was prepared on FTO conductive substrate by method or inkjet method 2 Thin film of dense layer, heated and annealed at 500°C for 30min.

[0037] Step S2, use 15ml of concentrated hydrochloric acid, 15ml of deionized water and 0.7ml of butyl titanate to conf...

Embodiment 2

[0043] A method for preparing a perovskite solar cell, comprising the steps of:

[0044] Step S1, select FTO (tin oxide doped with F) conductive glass with a surface roughness of less than 1 nm as the conductive substrate, first clean the FTO conductive substrate, dry it with dry nitrogen after cleaning, and perform ultraviolet light and ozone treatment , to obtain a clean FTO conductive substrate; prepare TiO on a clean FTO conductive substrate (tin oxide doped with F) 2 Dense layer film, the film thickness is 30nm, the specific operation method is: prepare a certain concentration (0.25mol / L) titanium isopropoxide ethanol solution, use spin coating method or spray coating method or roller coating method or spray pyrolysis method or LB film TiO was prepared on FTO conductive substrate by method or inkjet method 2 Thin film of dense layer, heated and annealed at 500°C for 30min.

[0045] Step S2, use 15ml of concentrated hydrochloric acid, 15ml of deionized water and 0.7ml of...

Embodiment 3

[0051] A method for preparing a perovskite solar cell, comprising the steps of:

[0052] Step S1, select FTO (tin oxide doped with F) conductive glass with a surface roughness of less than 1 nm as the conductive substrate, first clean the FTO conductive substrate, dry it with dry nitrogen after cleaning, and perform ultraviolet light and ozone treatment , to obtain a clean FTO conductive substrate; prepare TiO on a clean FTO conductive substrate (tin oxide doped with F) 2 Dense layer film, the film thickness is 30nm, the specific operation method is: prepare a certain concentration (0.25mol / L) titanium isopropoxide ethanol solution, use spin coating method or spray coating method or roller coating method or spray pyrolysis method or LB film TiO was prepared on FTO conductive substrate by method or inkjet method 2 Thin film of dense layer, heated and annealed at 500°C for 30min.

[0053] Step S2, use 15ml of concentrated hydrochloric acid, 15ml of deionized water and 0.7ml of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap