Wet-process coupling catalytic oxidation waste gas treatment process and device thereof

A waste gas treatment device and catalytic oxidation technology, which are applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of low acquisition concentration, difficulty in acquisition, low production rate and concentration of hydroxyl radicals, etc., and improve absorption and capture. effect, small pressure drop, effect of small reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

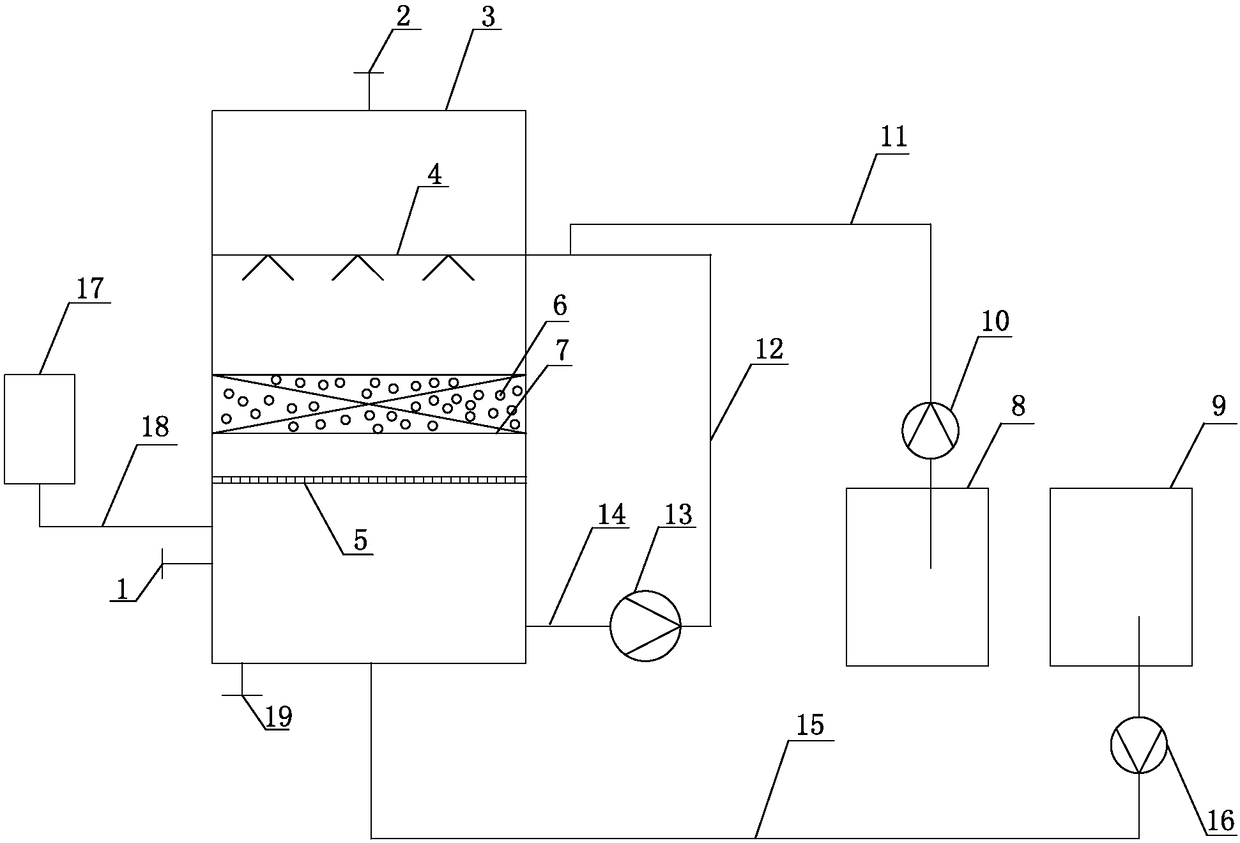

[0040] The waste gas treated in this embodiment is 10000m 3 / h Bio-fermentation pharmaceutical factory drying waste gas, the main pollution component is organic acid malodorous substances.

[0041] The wet-process coupled catalytic oxidation waste gas treatment process of the present invention uses hydrogen peroxide as the oxidant and is added by the oxidant addition system 8. The waste gas enters the catalytic oxidation reaction tower 3 with a gas redistributor 5 at the bottom, and adopts homogeneous catalysts and heterogeneous catalysts. In the catalyst coupling system, the exhaust gas and the homogeneous catalyst and the heterogeneous catalyst undergo a catalytic oxidation reaction in the catalytic oxidation reaction tower 3, and the pH of the reaction medium is adjusted to 4 with acid or alkali; the pollutants in the exhaust gas are degraded under normal temperature conditions.

[0042] among them:

[0043] The homogeneous catalyst is added by the homogeneous catalyst addition sy...

Embodiment 2

[0054] The waste gas treated in this embodiment is 5000m 3 / h Chemical additives process waste gas, and the main pollutants are ethylene oxide, styrene, etc.; the waste gas treatment device used in the second embodiment is the same as that in the first embodiment.

[0055] The wet-process coupled catalytic oxidation waste gas treatment process of the present invention uses hydrogen peroxide as the oxidant and is added by the oxidant addition system 8. The waste gas enters the catalytic oxidation reaction tower 3 with a gas redistributor 5 at the bottom, and adopts homogeneous catalysts and heterogeneous catalysts. In the catalyst coupling system, the exhaust gas and the homogeneous catalyst and the heterogeneous catalyst undergo a catalytic oxidation reaction in the catalytic oxidation reaction tower 3, and the pH of the reaction medium is adjusted to 3 with acid or alkali; the pollutants in the exhaust gas are degraded under normal temperature conditions.

[0056] among them:

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com