Preparation method of high-strength degradable nanometer medical porous titanium-based composite material

A titanium-based composite material and nanoporous technology, which is applied in the field of medical implants, can solve the problems of poor affinity and degradability, inability of bone tissue to grow in, and cannot heal, and achieves improved medical functions and good degradability. , the effect of good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

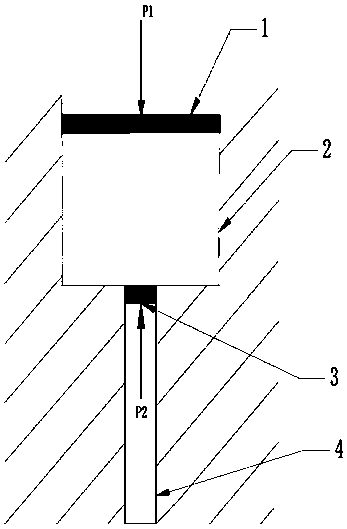

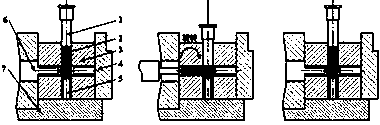

[0034] Example 1: Preparation method of a high-strength nano-medicine porous titanium-based composite material

[0035] Ti powder, Mg particles (purity 99.6%), Si particles (purity 99.9%), V particles, Ag particles and TiC-SiC-ZrC whisker particles in a molar ratio of 40:10:45:3:1.5: 0.5 Evenly mixed and prepared, bonded with isopropanol, then extruded on a press through a press die, and dried at room temperature for 5 minutes, so that the isopropanol evaporated and the adhesion between the particles disappeared, and finally formed D10mm×68mm rod-shaped sample; the rod-shaped sample is put into the sheath, rotated repeatedly through the cross-shaped channel, and extruded 4 times, resulting in severe plastic deformation to obtain a titanium-based composite material with nano-grain structure. The cross-shaped mold channel is produced The rod-shaped nanomaterials were soaked in 5 L of sodium hydroxide (NaOH) aqueous solution at 60 °C for 12 h to remove Si, and then, the porous Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com