Weathering resistant steel surface stabilization rust layer rapid generation treatment agent and use method thereof

A weathering steel, stabilization technology, applied in the direction of metal material coating technology, etc., can solve the problems of unsuitable treatment methods, many processing steps, affecting the practicability of weathering steel treatment agents, etc., to achieve low preparation and construction costs, no organic Solvent pollution, the effect of improving the sag phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is described in detail.

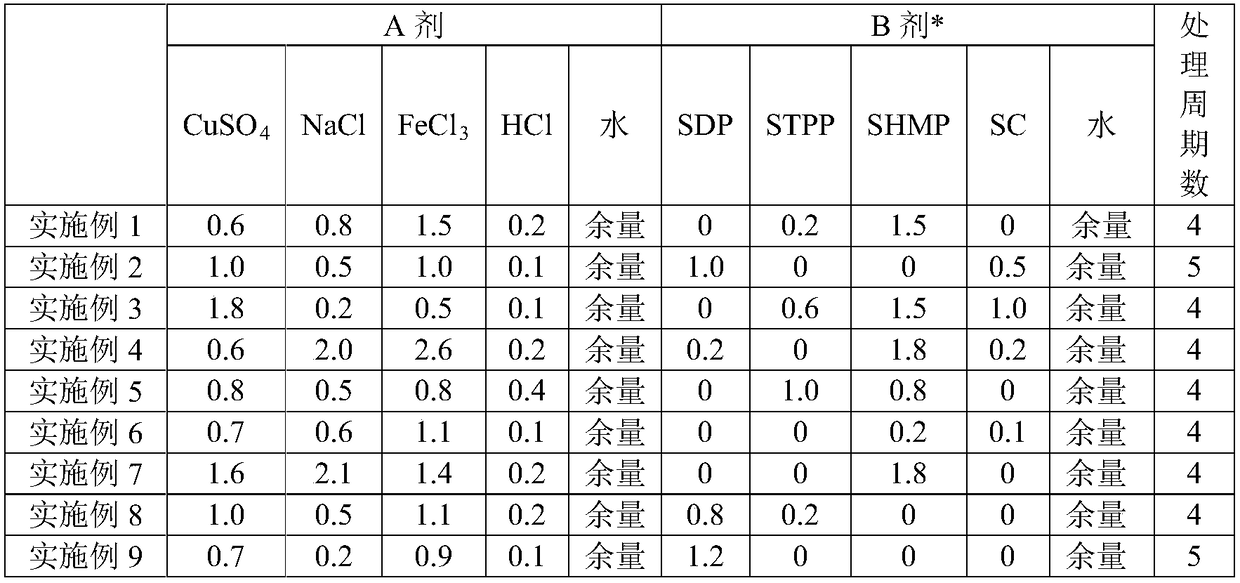

[0016] Table 1 embodiment and comparative example composition (mass%) and processing technology

[0017]

[0018]

[0019] *In agent B: SDP is NaH 2 PO 4 ; STPP is Na 5 P 3 o 10 ; SHMP is (NaPO 3 ) 6 ;SC is C 6 h 5 Na 3 o 7 2H 2 O.

[0020] In Agent A: the HCl is commercially available 30% hydrochloric acid.

[0021] Table 2 Treatment effect evaluation results

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com