A water-soluble solderable nickel protectant

A water-soluble, protective agent technology, applied in liquid chemical plating, coating, metal material coating process, etc., can solve the problems of easy residual corrosion of acid ions, poor weldability, complicated process, etc., to achieve no residual corrosion hidden danger Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 solderable nickel protective agent

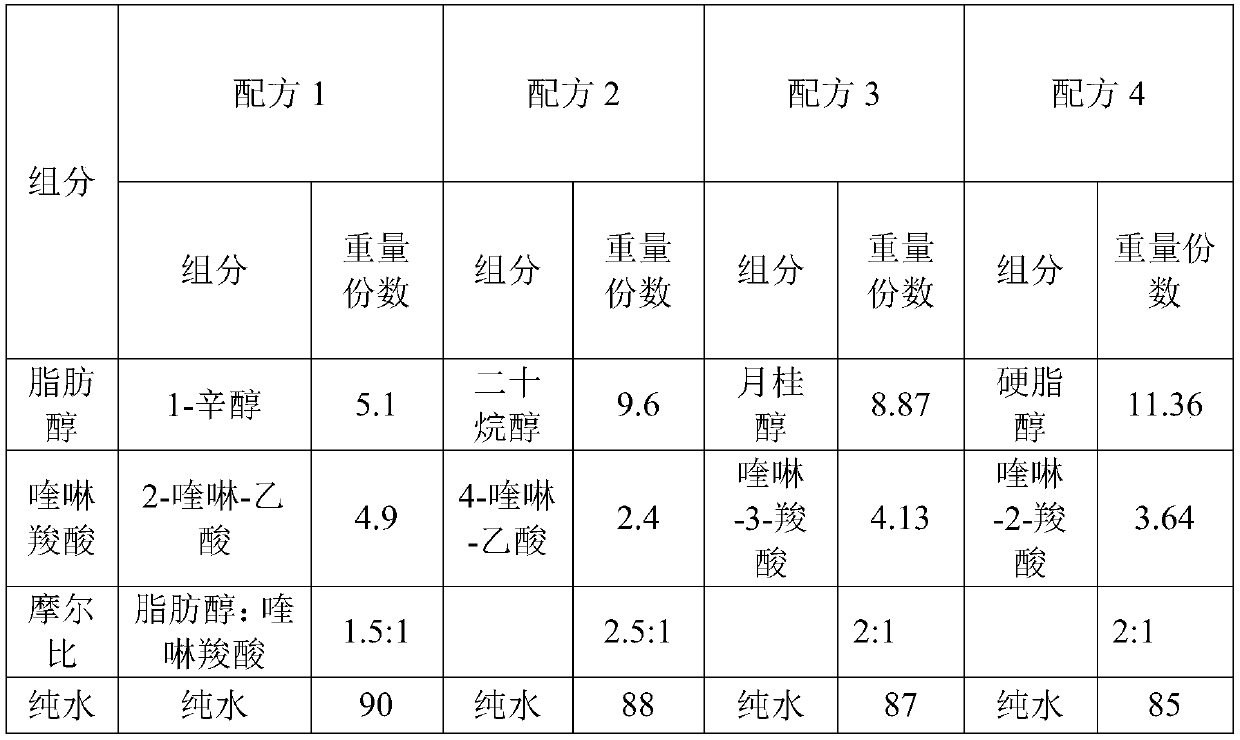

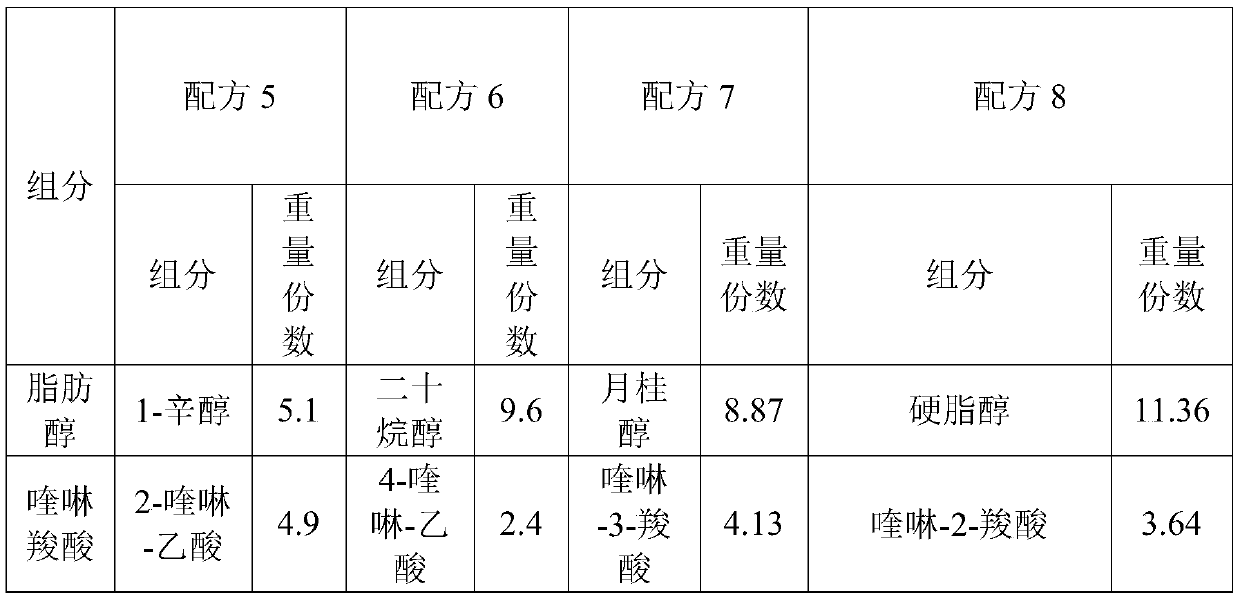

[0044] Table 1

[0045]

[0046] Table 2

[0047]

[0048]

[0049] According to the 8 formulations in Table 1 and Table 2, concentrates were prepared respectively, and diluted with pure water to a concentration of 5% to make a working solution.

Embodiment 2

[0050] Embodiment 2 Solder performance test

[0051] Objective: To test the solder performance of fresh and long-term nickel coatings treated with different formulations by using the simple immersion tin method commonly used in the industry.

[0052] Test workpiece samples:

[0053] Sample 1: Fresh nickel surface. Nickel-plated solder feet on copper, electroplating process, nickel layer thickness 1.0-2μm (40-80μ").

[0054] Sample 2: long-term nickel surface. Nickel-plated solder feet on copper, electroplating process, nickel layer thickness 1.0-2μm (40-80μ"). Open and place in the air for 3 months.

[0055] Solderability protection treatment conditions:

[0056] Heat the 8 formula working solutions in Example 1 to 50°C, soak the fresh nickel surface directly in the 8 formula working solutions for 5 seconds, take out the hot air and dry it; the long-standing nickel surface adopts the cathode electrolysis auxiliary process, and the workpiece is used as the cathode , stainl...

Embodiment 3

[0059] Embodiment 3 nickel coating corrosion resistance test

[0060] Objective: To test the corrosion resistance and anti-oxidation ability of nickel coatings treated with different formulations by neutral salt spray test.

[0061] Test workpiece samples:

[0062] Sample 1: electroless nickel plating on copper material, the thickness of the nickel layer is 2 μm (80 μ”).

[0063] Sample 2: Electroplated nickel on iron material, the thickness of the nickel layer is 2.5 μm (100 μ”).

[0064] Solderability protection treatment conditions: heat the 8 formula working solutions in Example 1 to 55°C, soak samples 1 and 2 for 10 seconds, take out the hot air and dry them.

[0065] At the same time, a blank control group was set, that is, no solderability protection treatment was performed.

[0066] The test workpiece sample is subjected to neutral salt spray test after being treated by the present invention, and the specific test method refers to the test standard of GB / T10125-2012...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com