Special multifunctional suspension type seed coating agent for spring-rice-region paddy

A multi-functional, insecticide technology, applied in the field of agriculture, can solve the problems of insufficient water and oxygen, low seedling emergence rate, low seedling rate, and difficulty in controlling pest damage, achieving low cost, low shedding rate, and delaying germs The effect of drug resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

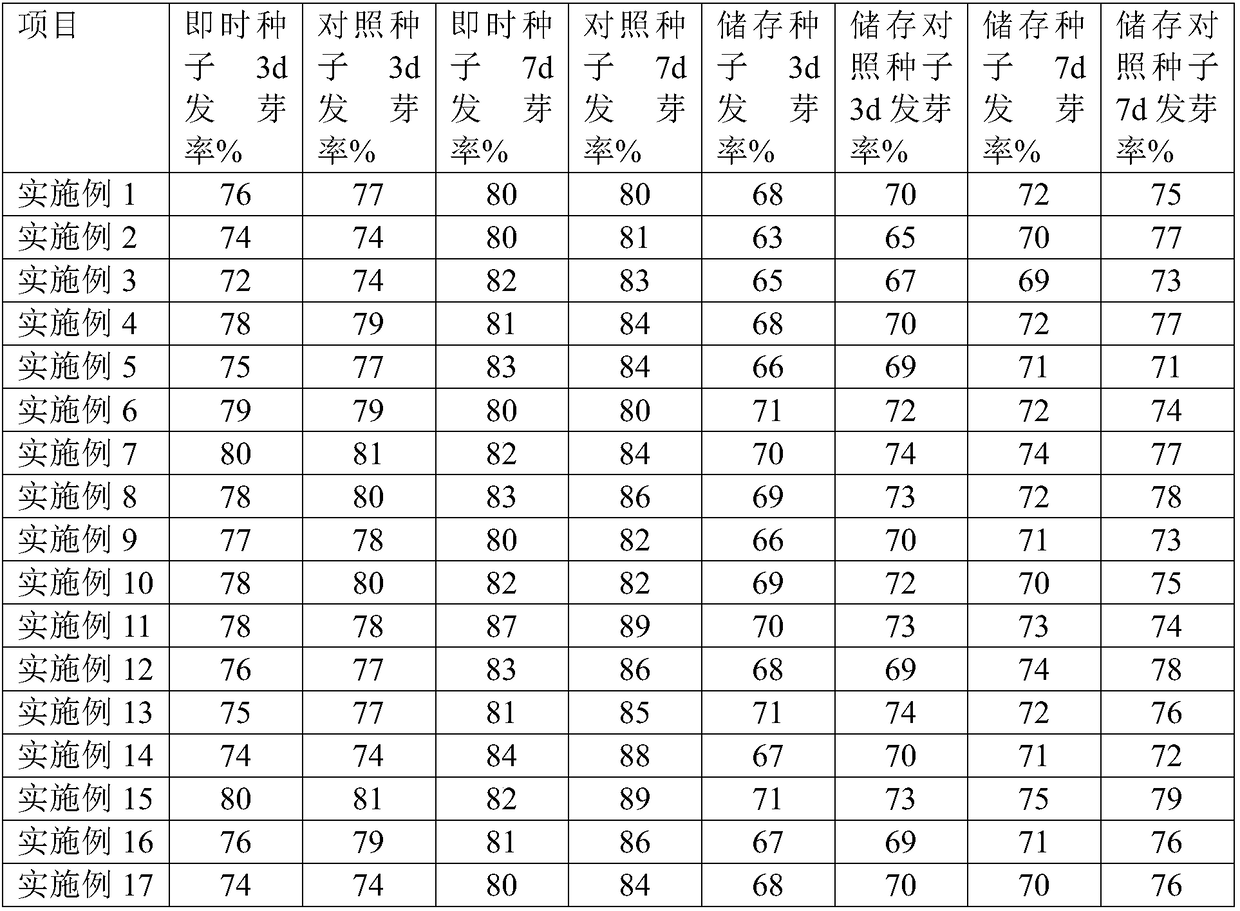

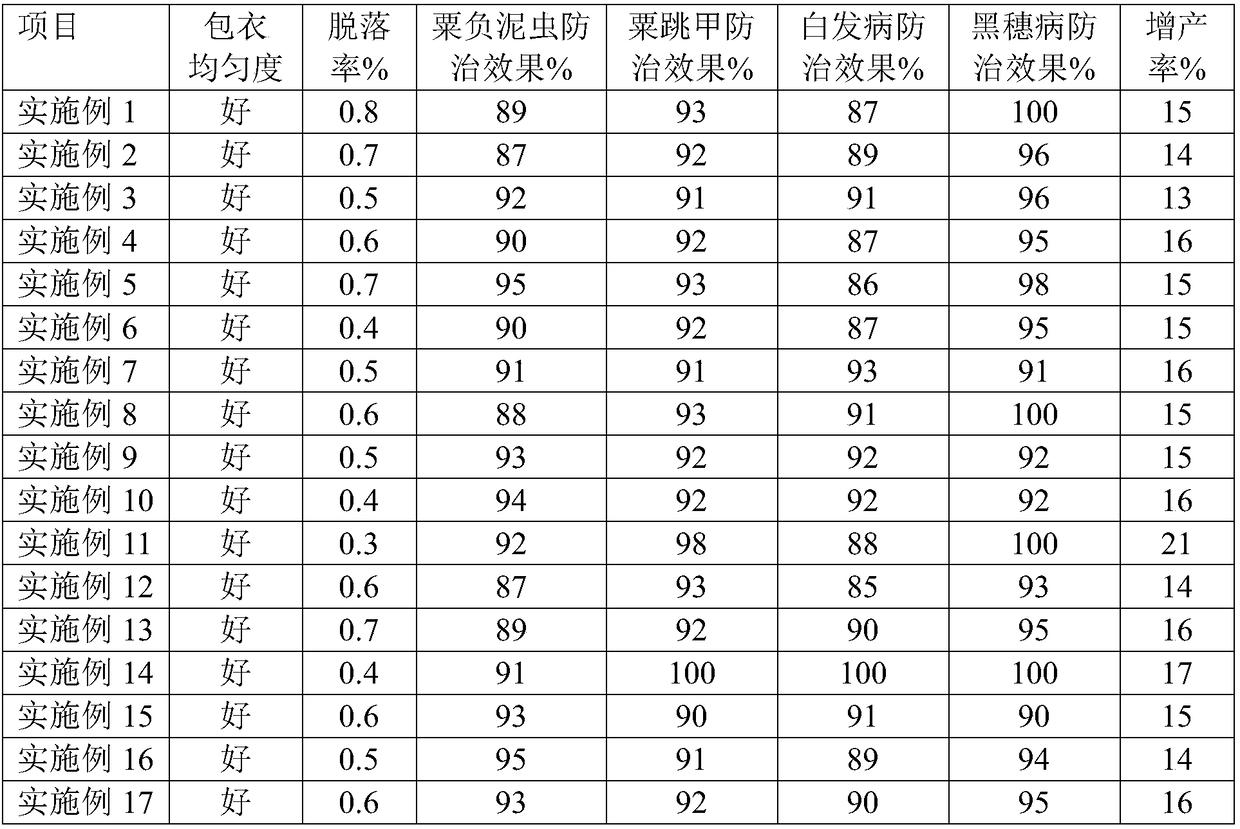

Examples

Embodiment 1

[0028] By weight percentage, imidacloprid 10%, dimethomorph 5%, propineb 10%, carbendazim 1%, brassinolide 0.05%, film-forming agent 2%, sodium lignosulfonate 2%, Glycerol 3%, foam enemy 0.2%, bright red 0.5%, water balance.

Embodiment 2

[0030] By weight percentage, thiamethoxam 20%, dimethomorph 3%, propineb 15%, carbendazim 5%, rooting powder 0.08%, film forming agent 3%, sodium methylene naphthalene sulfonate 1% , calcium lignosulfonate 2%, urea 4%, silicone 0.3%, strong rose red 0.6%, water balance.

Embodiment 3

[0032] By weight percentage, imidacloprid 20%, dimethomorph 10%, propineb 5%, carbendazim 1%, sodium nitrophenolate 0.1%, film forming agent 4%, dispersant 4%, glycerol 2 %, urea 3%, foam enemy 0.25%, permanent bright red F2R 0.7%, water balance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com