Sulfur-indium-zinc, gold and carbon nitride two-dimensional lamellar composite photocatalyst preparation method

A composite catalyst, two-dimensional layered technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effects of increased contact area, easy operation, and strong photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Take 7.3525g of C 6 h 5 Na 3 o 7 2H 2 O was dissolved in 50mL deionized water and stirred for 30min;

[0027] 2) Take 2.5mL of 0.01M / L HAuCl 4 , dilute to 100mL, add 200uL of sodium citrate solution prepared in step 1) after heating to boiling, keep boiling for 15min, restore the volume to 100mL, cool to room temperature, and obtain a stable gold colloid mixed solution;

[0028] 3) Add 0.5g g-C 3 N 4 Dissolve in 52.5mL ethanol and sonicate for 30min;

[0029] Ultrasonic conditions: ultrasonic frequency is 40kHz, ultrasonic power is 150W;

[0030] 4) 0.0176g Zn(NO 3 ) 2 ·6H 2 0,0.0045g In(NO 3 ) 3 4.5H 2 O, 0.0572g L-Cysteine was dissolved in 17.5mL glycerol and 10mL step 2) gold colloid mixed solution gained, then stirred for 15min;

[0031] 5) Mix the two solutions obtained in step 3) and 4) and stir for 30min to make g-C 3 N 4 Adsorb free ions and L-Cysteine molecules to obtain ZnIn 2 S 4 / Au / g-C 3 N 4 The precursor solution;

[0032] 6) Tra...

Embodiment 2

[0036] Embodiment 2, with embodiment 1, difference is,

[0037] 4) 0.0528g Zn(NO 3 ) 2 ·6H 2 0,0.0135g In(NO 3 ) 3 4.5H 2 O, 0.1716g L-Cysteine was dissolved in 17.5mL glycerol and 10mL step 2) gold colloid mixed solution gained, then stirred for 15min;

[0038] 5) Mix the two solutions obtained in step 3) and 4) and stir for 30min to make g-C 3 N 4 Adsorb free ions and L-Cysteine molecules to obtain ZnIn 2 S 4 / Au / g-C 3 N 4 The precursor solution;

[0039] 6) Transfer the precursor solution obtained in step 5) into a 100mL stainless steel hydrothermal reaction kettle with polytetrafluoroethylene lining, and react at 180°C for 24h to obtain a powder sample.

[0040] The prepared ZnIn of this embodiment 2 S 4 / Au / g-C 3 N 4 g-C in two-dimensional layered composite catalysts 3 N 4 with ZnIn 2 S 4 The mass ratio is 1:0.15.

Embodiment 3

[0041] Embodiment 3, with embodiment 1, difference is,

[0042] 4) 0.088g Zn(NO 3 ) 2 ·6H 2 0, 0.0225g In(NO 3 ) 3 4.5H 2 O, 0.286g L-Cysteine was dissolved in 17.5mL glycerol and 10mL step 2) gold colloid mixed solution gained, then stirred for 15min;

[0043] 5) Mix the two solutions obtained in step 3) and 4) and stir for 30min to make g-C 3 N 4 Adsorb free ions and L-Cysteine molecules to obtain ZnIn 2 S 4 / Au / g-C 3 N 4 The precursor solution;

[0044] 6) Transfer the precursor solution obtained in step 5) into a 100mL stainless steel hydrothermal reaction kettle lined with polytetrafluoroethylene, and react at 160°C for 26h to obtain a powder sample.

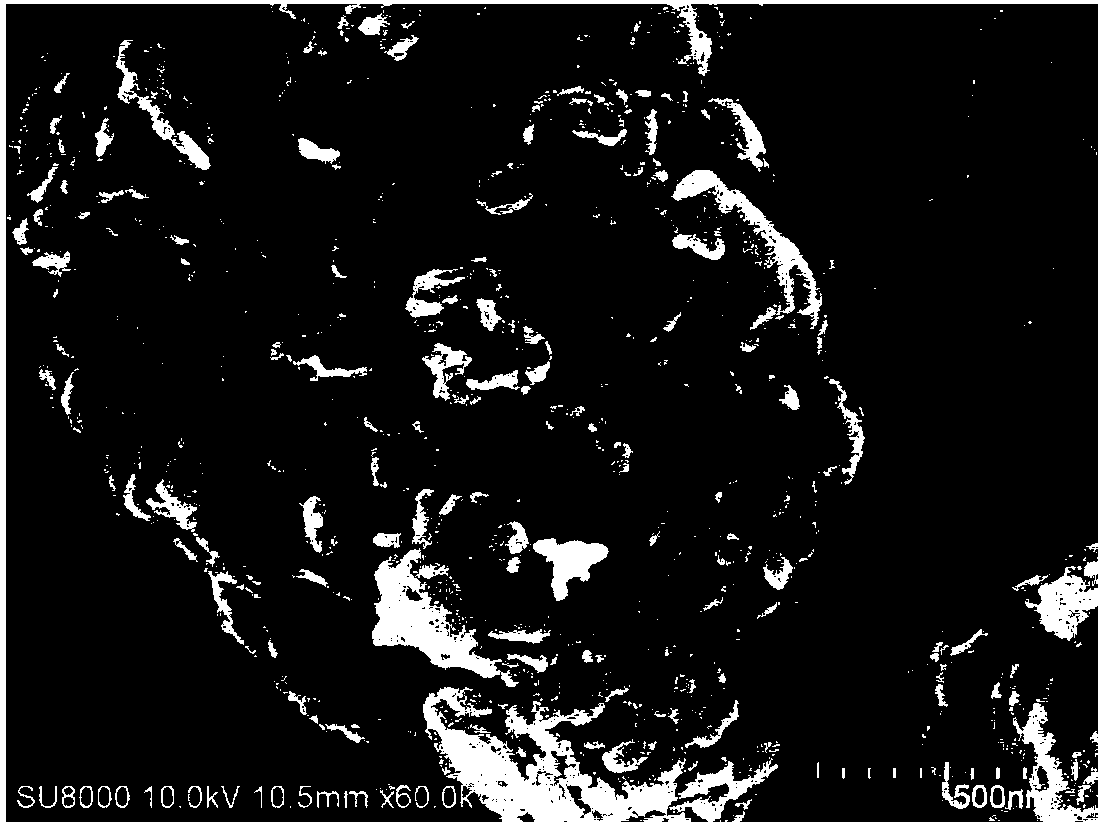

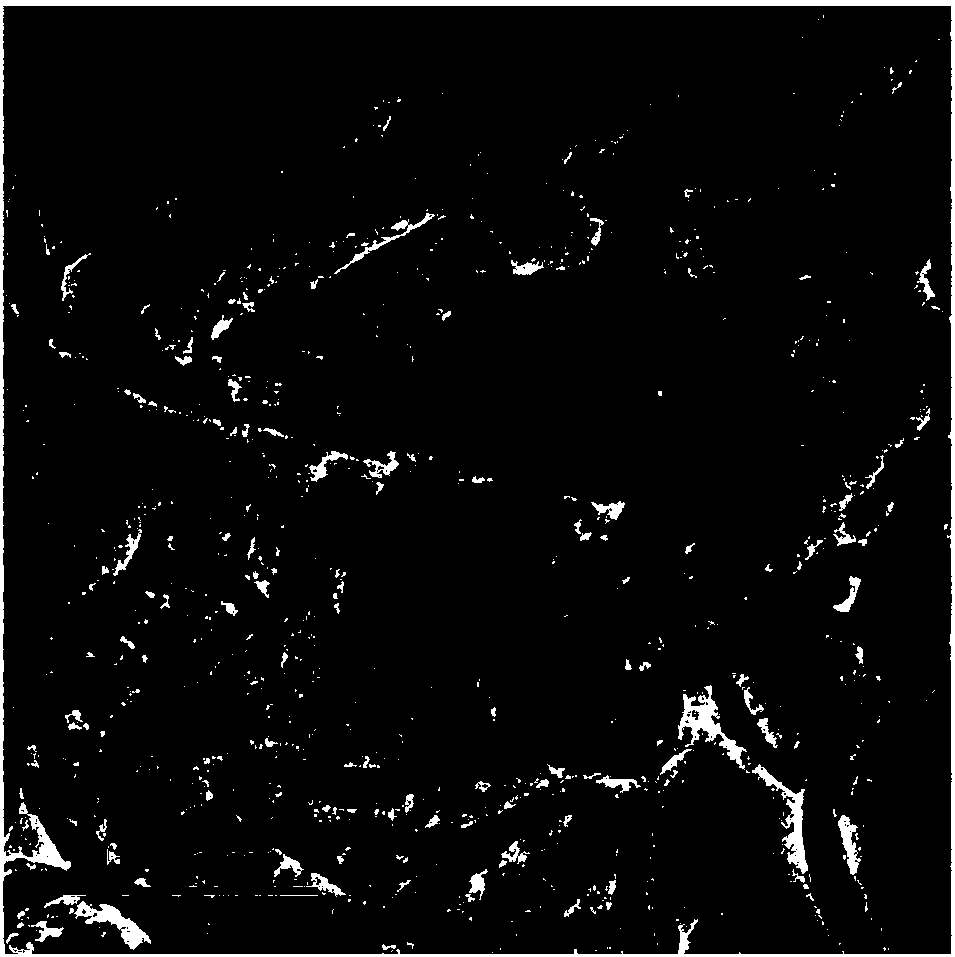

[0045] The ZnIn prepared in this embodiment 2 S 4 / Au / g-C 3 N 4 g-C in two-dimensional layered composite catalysts 3 N 4 with ZnIn 2 S 4 The mass ratio is 1:0.25. Powdered ZnIn 2 S 4 / Au / g-C 3 N 4 The scanning electron micrographs of the two-dimensional layered composite catalyst are shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com