Porous nickel framework material and preparation method thereof

A framework material and porous nickel technology, which is applied in the field of preparation of metal functional materials, can solve the problems of low density and high specific strength, and achieve the effects of narrow pore size distribution, good density and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Step 1: Pretreatment of Porous Nickel Spherical Metal Powder

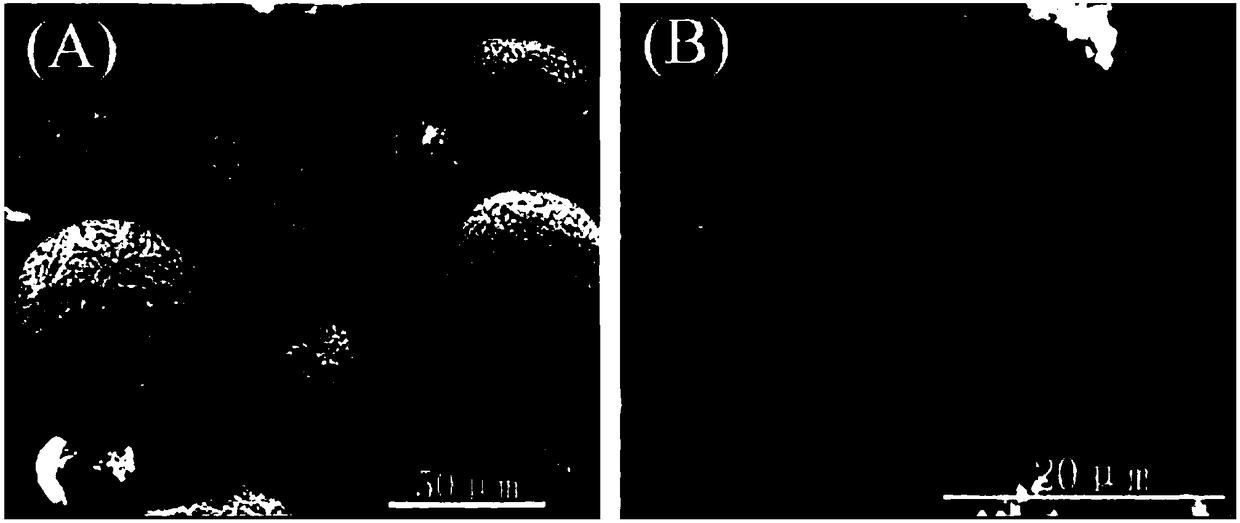

[0039] The porous nickel spherical metal powder used is ultrasonically cleaned and dried, and then sieved, and the powder with an average particle size ranging from 30 to 100 μm is sealed and stored for future use. The relevant performance and structural parameters of the porous nickel spherical metal powder prepared in this example are determined by the BET method as shown in Table 1. From Table 1, it can be seen that when the average particle size of the porous nickel spherical metal powder is 45-80 μm, the specific surface area is the largest and the pore diameter is the largest. Uniform distribution, better performance than porous nickel spherical metal powder with other particle sizes. figure 1 It is the scanning electron microscope (SEM) photo of the porous nickel spherical metal powder adopted in this example, figure 1 A is the surface topography of porous nickel spherical metal powder, figure 1 B i...

Embodiment 2

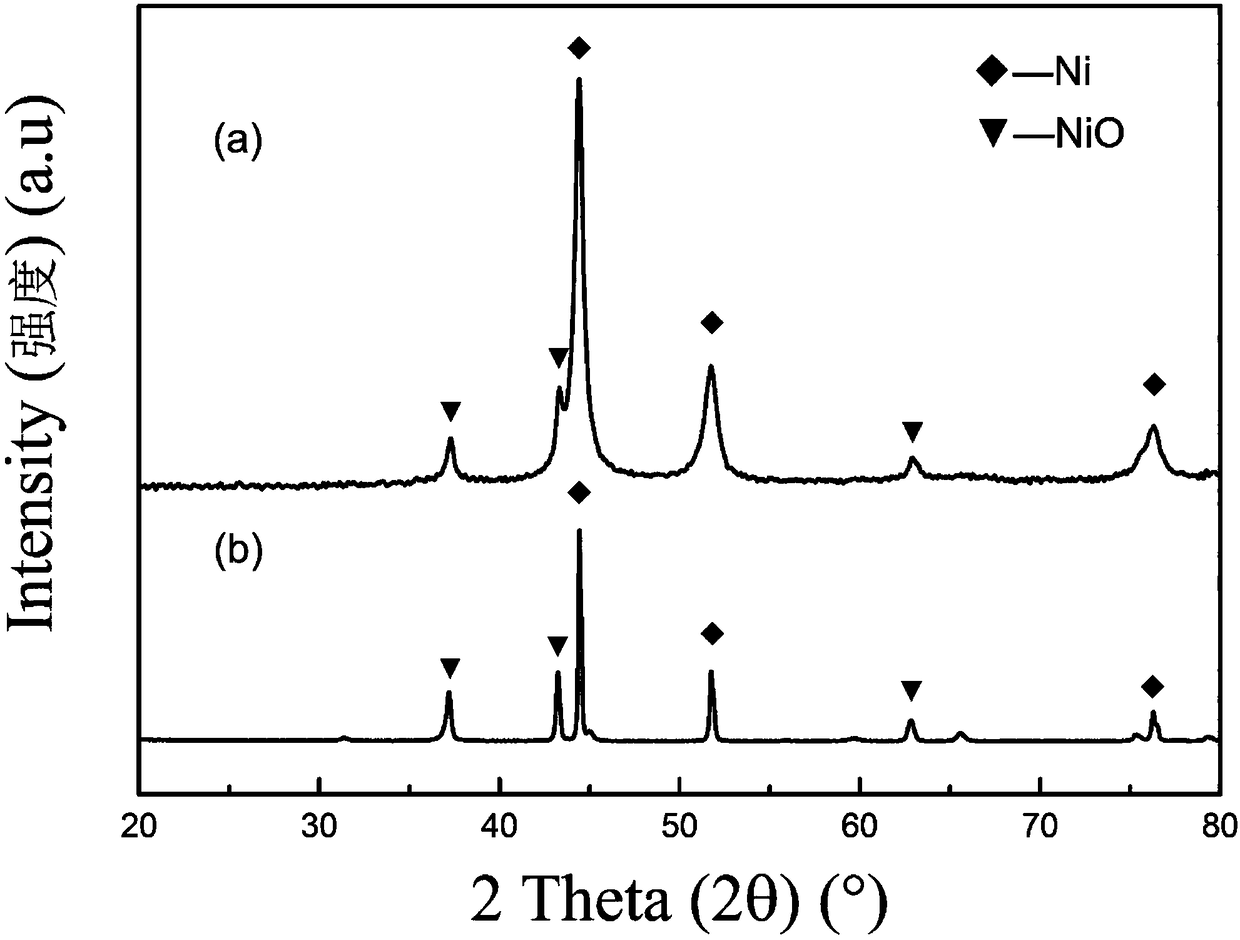

[0047] In this example, the average particle size sieved in Example 1 is 90 μm, and the average specific surface area is 44.308m 2 / g, porous nickel spherical metal powder with an average pore diameter of 30.12nm, ultrasonic cleaning and impurity removal and drying, weigh 45g of porous nickel spherical metal powder and place it in a graphite mold with a diameter of 30mm, adopt spark plasma sintering process, apply 11MPa The porous nickel spherical metal powder is pre-pressed by pressure, first heated to 300°C at a heating rate of 4°C / min, degassed for 0.8h, and then a pressure of 22MPa is applied to continue heating, and the heating rate is 105°C / min Heating to 700°C and keeping it warm for 8 minutes, and cooling to room temperature with the furnace after sintering, the porous nickel framework material can be obtained. Its microstructure is as Figure 5 As shown, after spark plasma sintering at a temperature of 700 °C, most of the porous nickel spherical metal powder has not ...

Embodiment 3

[0050] The average particle diameter sieved in Example 1 is 85 μm, and the average specific surface area is 44.308m 2 / g, porous nickel spherical metal powder with an average pore diameter of 30.12nm, ultrasonic cleaning and impurity removal and drying, weigh 45g of porous nickel spherical metal powder and place it in a graphite mold with a diameter of 30mm, adopt spark plasma sintering process, apply 13MPa The porous nickel spherical metal powder is pre-pressed under pressure, firstly heated to 300°C at a heating rate of 5°C / min, degassed for 0.9h, and then the pressure of 24MPa is applied to continue heating, and the heating rate is 110°C / min Heating to 750°C and keeping it warm for 10 minutes, and cooling to room temperature with the furnace after sintering, the porous nickel framework material can be obtained. Its microstructure is as Figure 7 As shown, the porous nickel spherical metal powder is still inside the material after spark plasma sintering at a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com