A kind of titanium-based composite brazing filler metal and its preparation and brazing method

A technology of titanium-based composite materials and composite solder, which is applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of poor wettability and low mechanical properties of solder, and achieve high mechanical strength and uniform weld structure Small size, excellent high-temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

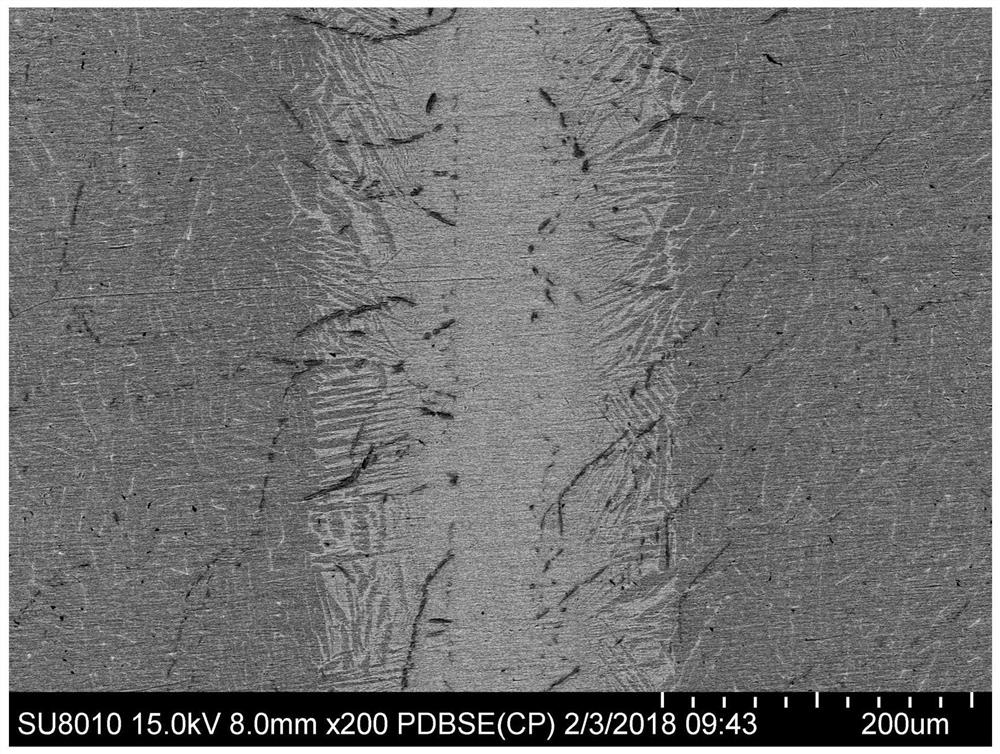

Image

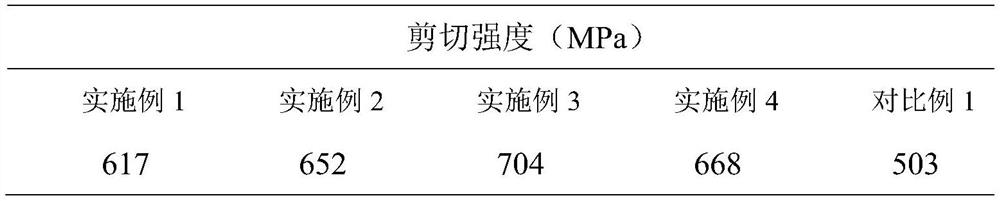

Examples

Embodiment 1

[0034] 1. Prepare titanium-based composite solder according to the following method

[0035] 1) Weigh the solder element powder on an electronic scale according to the mass percentage of Ti-20Ni-5Al-5Zr+1%C, wherein Ti is 69 parts by mass, Ni is 20 parts by mass, Al is 5 parts by mass, and Zr is 5 parts by mass parts by mass, and C is 1 part by mass.

[0036] 2) The alloying element powders with the above proportions are placed in an induction melting furnace and melted repeatedly 4 times to ensure that a solder alloy with a uniform structure is obtained. After cooling, a brazing filler metal ingot with uniform and fine composition is obtained.

[0037] 3) Place the above-mentioned ingot in the quartz tube in the vacuum stripping machine, and wait for melting again.

[0038] 4) Before melting, pump the vacuum in the vacuum belt machine to 8×10 -3 Pa, and then pass through the argon to wash the furnace, and then evacuate again to a vacuum degree of 8×10 -3 Pa, to avoid the ...

Embodiment 2

[0048] Using the Ti-20Ni-5Al-5Zr+1%C titanium-based composite solder prepared in Example 1, the TMCs titanium-based composite material base metal is brazed, and the temperature is raised to 1040 ° C for the second time and then kept for 30 minutes. Other conditions Same as Example 1.

Embodiment 3

[0050] Adopt the Ti-20Ni-5Al-5Zr+1%C titanium-based composite solder prepared in Example 1 to braze the TMCs titanium-based composite material base metal, heat it for 30 minutes after the second temperature rise to 1060 ° C, and other conditions Same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com