Soldering flux for halogen-free spray printing solder paste, and preparation method of soldering flux for halogen-free spray printing solder paste

A technology of flux and halogen, applied in the field of flux for halogen-free spray printing solder paste and its preparation, can solve problems such as plugging and wire drawing, and achieve the effects of high activity, improvement of stability and recovery of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

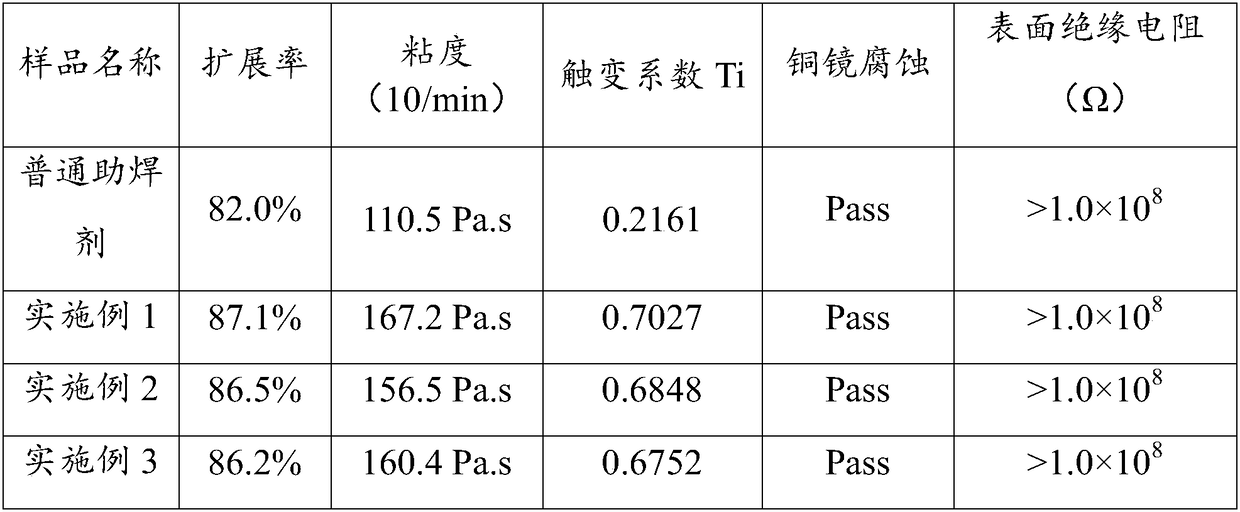

Examples

preparation example Construction

[0028] Embodiments of the present invention also provide a preparation method for the halogen-free soldering flux for jet printing solder paste, comprising the following steps:

[0029] After mixing the film-forming agent, thixotropic agent and co-solvent, adding the solvent isopropanol, heating and stirring at a temperature of 100-150°C to obtain the first mixture;

[0030] After the temperature of the first mixture drops to 50-65°C, organic acid activators, halogen-free activity enhancers, copper-dissolving inhibitors, halogen-free surfactants, antioxidants and antibacterial agents are added to the first mixture to obtain the second mixture. mixture;

[0031] The second mixture was stirred until completely dissolved and then cooled to room temperature.

[0032] At the same time, it should be noted that, in this embodiment, the solder paste can be prepared by using the above flux as follows:

[0033] Mix the above prepared flux for halogen-free jet printing solder paste wit...

Embodiment 1

[0042] This embodiment provides a halogen-free soldering flux for jet printing solder paste, which is prepared by the following preparation method:

[0043] S1: After mixing 20% of disproportionated rosin, 20% of maleic rosin, 9% of borate modified hydrogenated castor oil, 7.5% of sorbitol and 7.5% of diethylene glycol ether adding the solvent isopropanol, heating and stirring at a temperature of 100-150° C. to obtain the first mixture;

[0044] S2: After the temperature of the first mixture drops to 50-65°C, add 1.6% succinic acid, 1.2% adipic acid, 0.8% itaconic acid, 0.5% triisopropane Alcoholamine, 0.02% of BTA, 0.02% of BI, 0.1% of OP-10, 0.1% of BYK333, 0.01% of catechol, 0.01% of tert-butyl hydroquinone and 0.01% of BHA were added to the first A second mixture is obtained after the mixture;

[0045] S3: Stir the second mixture until completely dissolved and then cool to room temperature.

[0046] This embodiment also provides a kind of solder paste, which is prepar...

Embodiment 2

[0049] This embodiment provides a halogen-free soldering flux for jet printing solder paste, which is prepared by the following preparation method:

[0050] S1: After mixing 20% of polymerized rosin, 20% of maleic rosin, 8% of borate modified hydrogenated castor oil, 7.5% of sorbitol and 7.5% of diethylene glycol ether adding the solvent isopropanol, heating and stirring at a temperature of 100-150° C. to obtain the first mixture;

[0051] S2: After the temperature of the first mixture drops to 50-65°C, add 1.4% succinic acid, 0.6% malic acid, 1.6% adipic acid, 0.4% itaconic acid, 0.5% triisopropanolamine, 0.02% BTA, 0.02% MBT, 0.1% OP-10, 0.1% BYK333, 0.01% catechol, 0.01% tert-butyl hydroquinone and 0.01% BHT is added to the first mixture to obtain the second mixture;

[0052] S3: Stir the second mixture until completely dissolved and then cool to room temperature.

[0053] This embodiment also provides a kind of solder paste, which is prepared by the following method: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com