Organic fire retardant and preparation method thereof

A kind of flame retardant, organic technology, applied in the field of flame retardants, can solve the problems of halogenated flame retardants application restrictions, toxic and harmful gases, etc., and achieve good anti-dripping performance, good stability, and good appearance characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

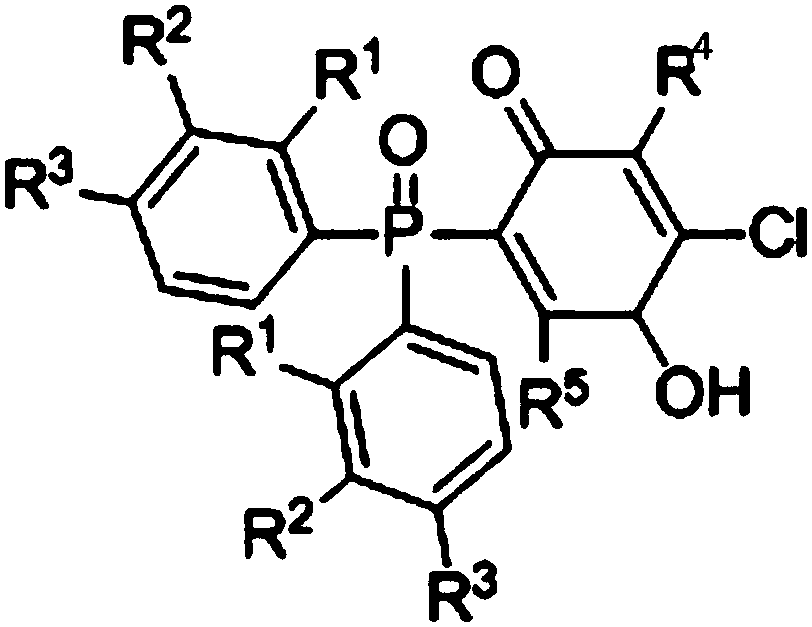

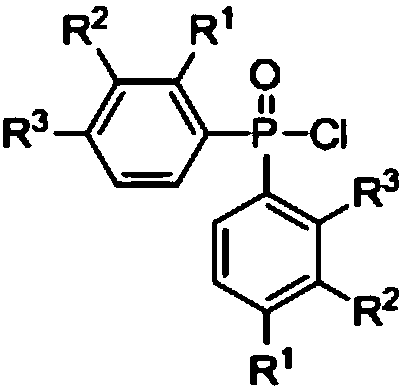

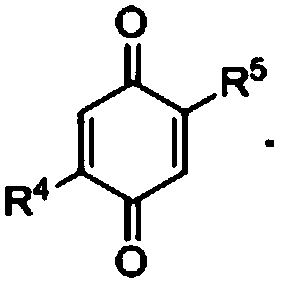

Method used

Image

Examples

Embodiment 1

[0029] In a 100mL reaction tube, add 6 mmol of diphenyl antimony chloride (R 1 , R 2 , R 3 , R 4 , R 5 , R 6 , R 7 , R 8 , R 9 , R 10 , R 11 , R 12 , R 13 The group is hydrogen), 9mmol aryl boronic acid (R 14 , R 15 , R 16 , R 17 , R 18 The group is hydrogen), 5 mol% nickel acetate, 2 equivalents of sodium carbonate, vacuum backfill nitrogen three times, add 40ml toluene under nitrogen atmosphere, and react at 120°C for 12h. After the reaction, the toluene was removed under reduced pressure, and the target product was obtained by recrystallization from ethyl acetate and n-hexane with a yield of 90%.

[0030] Add the nitrogen-containing organic antimony flame retardant prepared in the above example 1 into the epoxy resin to carry out the oxygen index test and the vertical combustion level test, and use the oxygen index meter to measure according to the GB / T 2406.1-2008 standard, and the sample size is 100mm× 6.5mm×3mm, according to the UL94 standard using a ver...

Embodiment 2

[0034] In a 100mL reaction tube, add 6 mmol of diphenyl antimony chloride (R 1 , R 2 , R 3 , R 4 , R 5 , R 6 , R 7 , R 8 , R 9 , R 10 , R 11 , R 12 , R 13 The group is hydrogen), 9mmol aryl boronic acid (R 14 , R 15 , R 17 , R 18 The group is hydrogen, R 16 For methyl), 5mol% nickel acetate, 2 equivalents of sodium carbonate, vacuum backfill nitrogen three times, add 40ml toluene under nitrogen atmosphere, and react at 120°C for 10h. After the reaction, the toluene was removed under reduced pressure, and the target product was obtained by recrystallization from ethyl acetate and n-hexane with a yield of 92%.

[0035] Add the nitrogen-containing organic antimony flame retardant prepared in the above example 2 into the epoxy resin to carry out the oxygen index test and the vertical combustion level test. According to the GB / T 2406.1-2008 standard, use the oxygen index meter to measure, the sample size is 100mm× 6.5mm×3mm, according to the UL94 standard using a v...

Embodiment 3

[0040] In a 100mL reaction tube, add 6 mmol of diphenyl antimony chloride (R 1 , R 2 , R 3 , R 4 , R 5 , R 6 , R 7 , R 8 , R 9 , R 10 , R 11 , R 12 , R 13 The group is hydrogen), 9mmol aryl boronic acid (R 14 , R 15 , R 17 , R 18 The group is hydrogen, R 16 Ethyl), 5 mol% nickel acetate, 2 equivalents of sodium carbonate, vacuum backfill nitrogen three times, add 40ml toluene under nitrogen atmosphere, and react at 120°C for 8h. After the reaction, the toluene was removed under reduced pressure, and the target product was obtained by recrystallization from ethyl acetate and n-hexane with a yield of 93%.

[0041] Add the nitrogen-containing organic antimony flame retardant prepared in the above example 3 into the epoxy resin to carry out the oxygen index test and the vertical combustion level test, and use the oxygen index meter to measure according to the GB / T 2406.1-2008 standard, and the sample size is 100mm× 6.5mm×3mm, according to the UL94 standard using a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap