Method for detecting volatile disinfection by-products in water by solid phase microextraction-gas chromatography-mass spectrometry technique

A technology of disinfection by-products and gas chromatography, which is used in measurement devices, instruments, scientific instruments, etc., can solve the problems of poor selectivity of target compounds, low detection sensitivity, high temperature resistance, etc., and achieves favorable adsorption, huge specific surface area, synthesis mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 takes MIL-96 as the preparation of the solid-phase microextraction probe of coating material

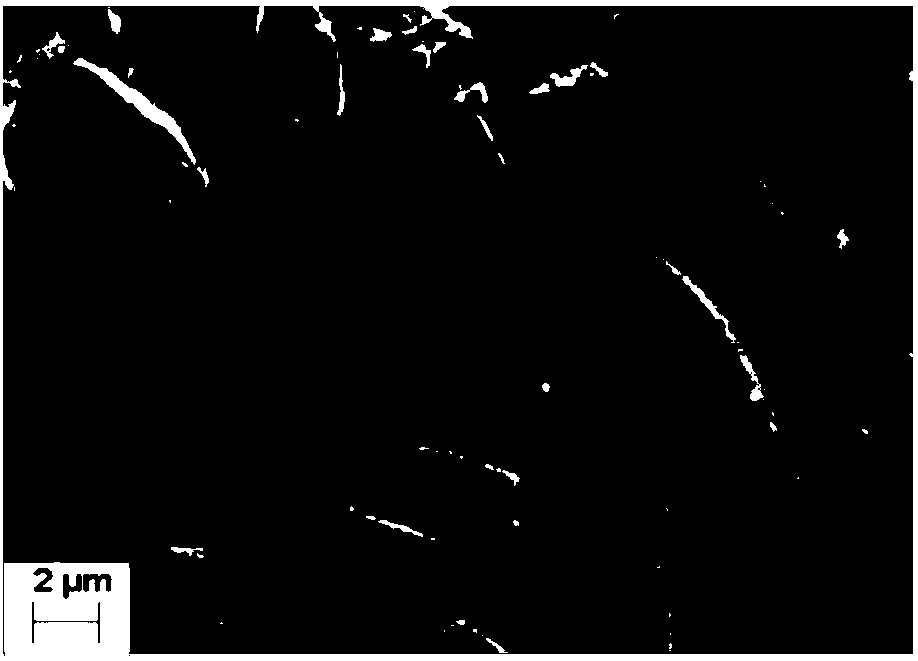

[0033] (1) Metal material MIL-96 was prepared by referring to existing literature: accurately weigh 2.088g of aluminum nitrate nonahydrate and 0.409g of trimesic acid, mix them in 30mL of deionized water, and stir at room temperature until completely dissolved. Then the mixture was transferred to a 100 mL polytetrafluoroethylene-lined stainless steel reactor and placed in an oven at 200 °C for 24 h. Finally, the reaction solution was washed at least 3 times with absolute ethanol and deionized water, and dried in a 60°C oven for 24 hours; (the prepared MIL-96 electron microscope image is shown in figure 1 shown)

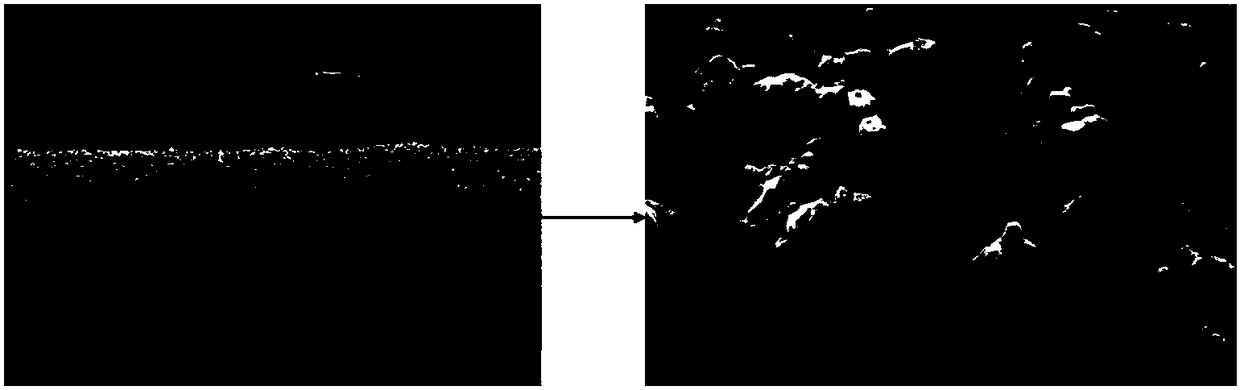

[0034] (2) The metal-organic material MIL-96 obtained through step (1) is adhered to the probe as a probe coating to obtain a solid-phase microextraction probe; (the MIL-96 electron microscope picture assembled on the probe Such as figure 2 shown)

[0...

Embodiment 2

[0036] The establishment of embodiment 2 methodology

[0037] (1) Adsorption treatment is carried out by using the aged probe in step (3), the adsorption conditions are: extraction temperature 25°C; extraction time 30min; stirring rate 300rpm; pH=6.0; salinity 30%;

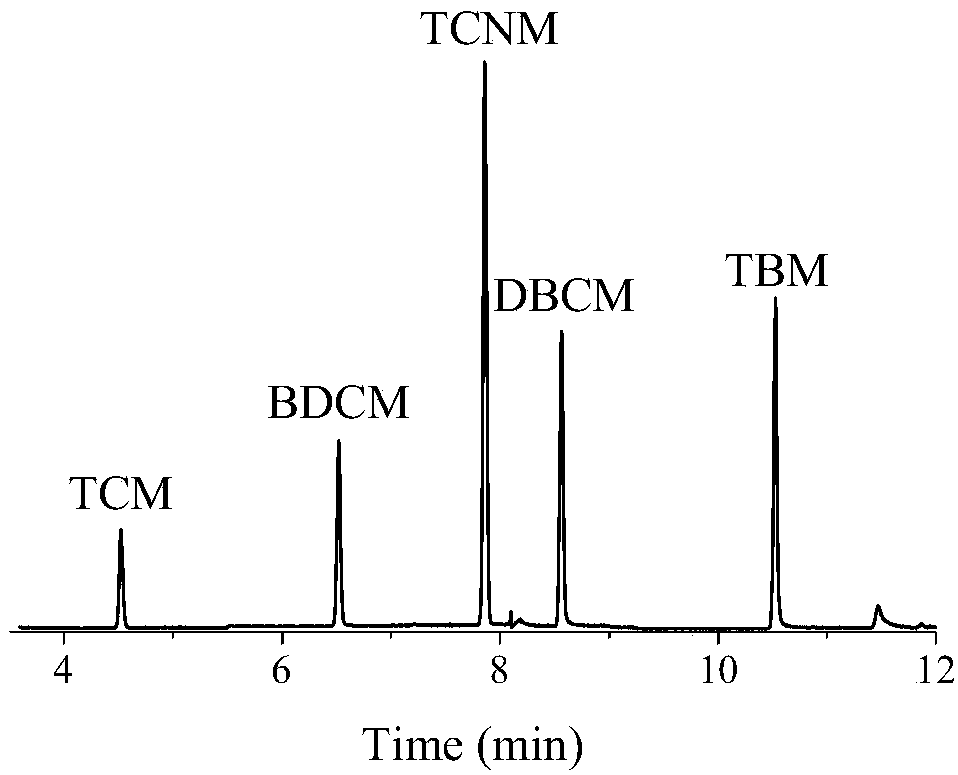

[0038] (2) The probe adsorbed in step (1) is directly desorbed by gas chromatography-mass spectrometry: the desorption time is 5 min; the desorption temperature is 200°C. The detection conditions are: chromatographic column: DB-624MS (30m×0.25mm×1.4μm); heating program: initial temperature of 50°C, keep for 3min, raise the temperature to 200°C at a speed of 20°C / min, keep for 2min; The speed of / min was increased to 280°C and kept for 1min; carrier gas: helium, flow rate: 1.0ml / min; mass spectrometer selected EI as ion source, and adopted SIM mode. (trihalomethane and trichloropicrin solid-phase microextraction chromatograms are as image 3 shown)

Embodiment 3

[0039] Example 3 Methodological Results

[0040] Using MIL-96 as the probe material, a new method for the complete detection of trihalomethanes and trichloropicrins was established through subsequent gas chromatography-mass spectrometry. The established method has a wide linear range of 0.02-50 μg / L, a detection limit of 0.0030-0.0110 μg / L, and a quantification limit of 0.0090-0.0332 μg / L, which is superior to traditional pretreatment methods (see Table 1). The above data show that the method has good precision, stability and reproducibility, and can be used for the accurate determination of volatile disinfection by-products trihalomethanes and trichloropicrin in water.

[0041] Table 1 MIL-96 is the methodology result of coating material

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com