Preparation method and production system for 2,4-dichlorophenoxyacetic acid

A technology of dichlorophenoxyacetic acid and dichlorophenoxyacetic acid ester, which is applied in the field of preparation method and production system of 2,4-dichlorophenoxyacetic acid, can solve the problem of low product purity, low product yield, reaction Low production capacity and other problems, to achieve the effect of less hydrolysis by-products, high conversion rate and yield, and fast reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

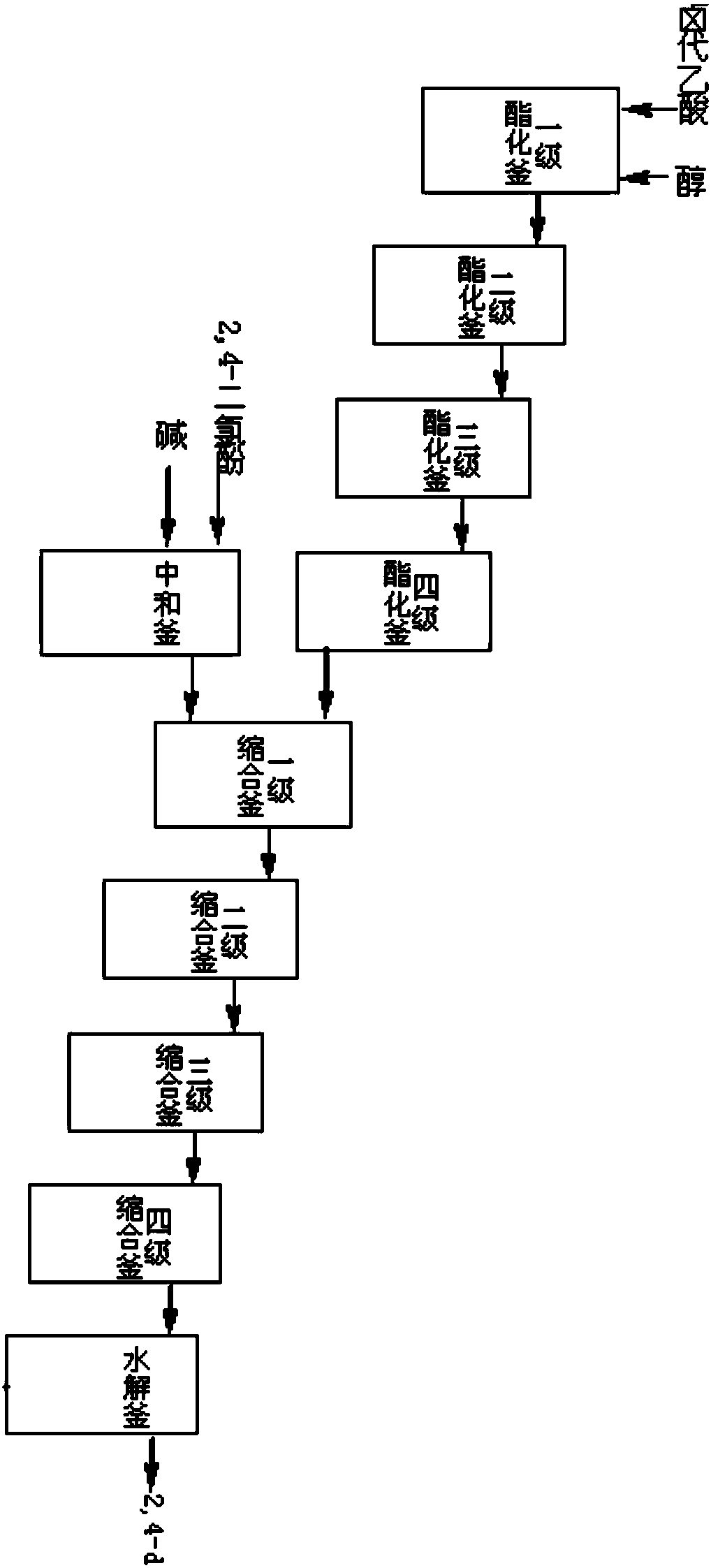

[0026] The invention provides a kind of preparation method of 2,4-dichlorophenoxyacetic acid, comprises the steps:

[0027] A) Alcohol and halogenated acetic acid undergo the esterification reaction of 3-5 stages of overflow dehydration to obtain halogenated acetate;

[0028] B) After the haloacetate is mixed with 2,4-dichlorophenoxylate, 2,4-dichlorophenoxyacetate is obtained through 3-5 stages of continuous condensation reaction;

[0029] C) hydrolyzing the 2,4-dichlorophenoxyacetic ester to obtain 2,4-dichlorophenoxyacetic acid.

[0030] The preparation method provided by the invention can overcome the low reaction capacity, incomplete reaction, many hydrolysis by-products, low product yield, low product purity, large consumption of raw materials, large amount of waste water, and difficult control of waste gas discharge in the prior art. And other issues.

[0031] In the embodiment of the present invention, the haloacetate is firstly prepared by the following method: the ...

Embodiment 1

[0070] Put 2000g of butanol, 950g (10mol) of chloroacetic acid and 1g of concentrated sulfuric acid into the primary esterification tank, mix and stir, desolventize and dehydrate at 80°C for 1 hour, and then enter the secondary and tertiary esterification tanks through overflow in sequence, and the feed rate is 2000g / h, and the residence time of each stage is controlled at 1h to obtain butyl chloroacetate.

[0071] Mix and stir 1640g (10mol) of 2,4-dichlorophenol and 1250g (10mol) of aqueous sodium hydroxide solution with a mass fraction of 32%, and raise the temperature to 70°C to obtain a sodium 2,4-dichlorophenate solution.

[0072] Put the 2,4-dichlorophenate sodium solution into the first-stage condensation kettle and mix it with the butyl chloroacetate obtained by esterification, stir at 80°C for 0.5h, and then enter the second, third, and fourth-stage condensation kettles through overflow , the feeding rate of butyl chloroacetate is 2200g / h, the residence time of each ...

Embodiment 2

[0074] Mix and stir 2000g ethanol, 1400g (10mol) bromoacetic acid and 1g concentrated sulfuric acid, desolventize and dehydrate at 100°C for 1.5h, then enter the second and third stage esterification kettles through overflow, the feed rate is 1500g / h, each stage stays The time was controlled at 1.5h to obtain ethyl bromoacetate.

[0075] 1640g (10mol) of 2,4-dichlorophenol and 1122g (10mol) of potassium hydroxide aqueous solution with a mass fraction of 50% were mixed and stirred, and the temperature was raised to 70°C to obtain potassium 2,4-dichlorophenolate solution.

[0076] Put the 2,4-dichlorophenate potassium solution into the ethyl bromoacetate obtained by esterification and mix it into the first-stage condensation kettle, stir at 90°C for 0.5h, and then enter the second, third, and fourth-stage condensation kettles in turn through overflow, The feeding rate of ethyl bromoacetate is 2000g / h, the residence time of each stage is controlled at 0.5h, then the condensation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com