Side chain sulfonated polyimide/perfluorosulfonic acid composite membrane, preparation method and application thereof

A sulfonated polyimide, perfluorosulfonic acid technology, applied in the direction of separator/film/diaphragm/spacer element, electrochemical generator, fuel cell, etc., can solve the problem of not particularly effectively improving the sulfonated polyamide The chemical stability of imine membrane, unfavorable composite membrane uniformity and high mechanical properties, and the chemical stability of composite membrane are not easy to achieve the effect of excellent mechanical properties and proton selection properties, excellent hydrolytic stability, chemical stability and dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

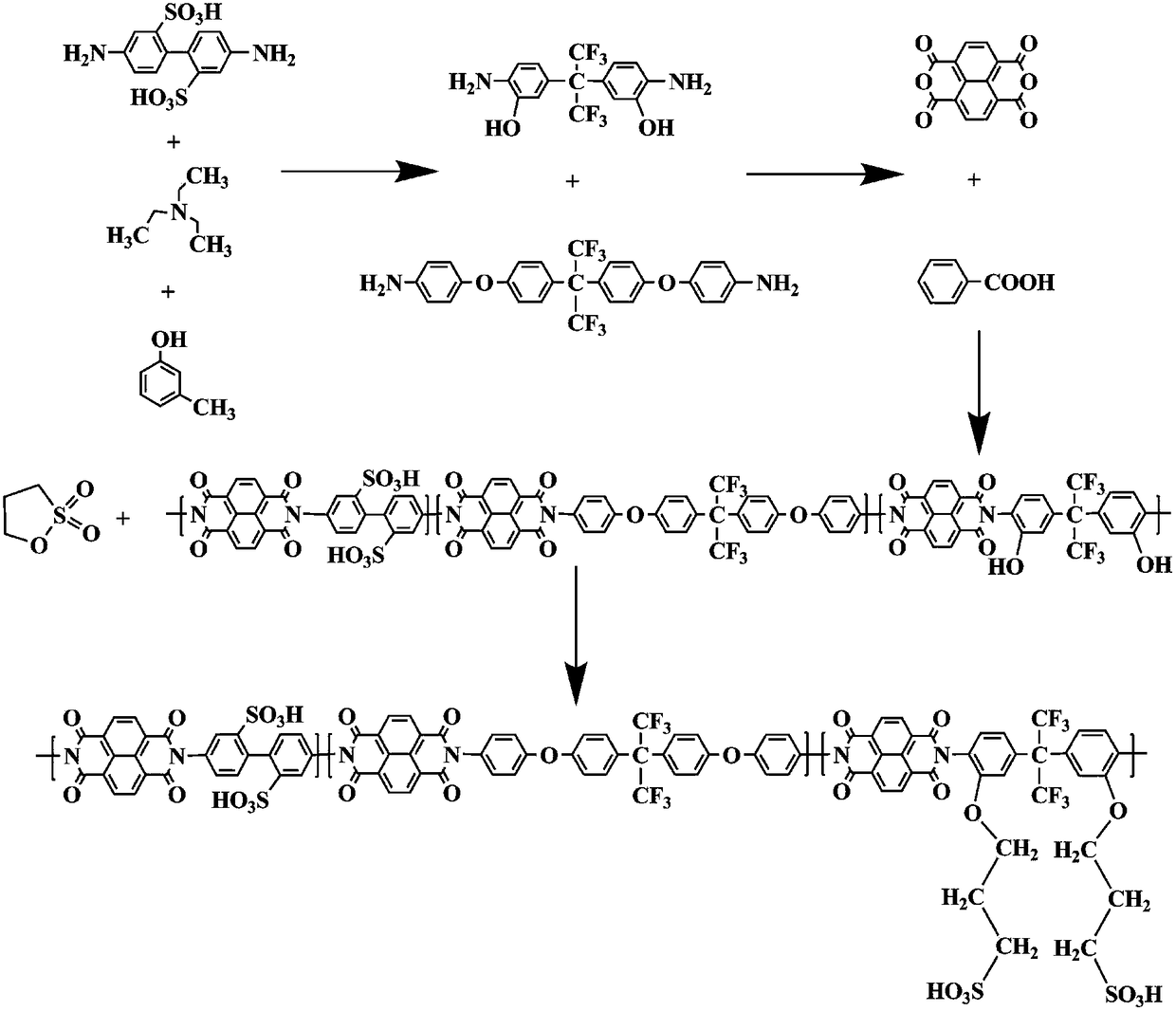

[0048] A side-chain type sulfonated polyimide / perfluorosulfonic acid composite membrane of the present invention has a thickness of 45 μm, and the side-chain type sulfonated polyimide polymer and perfluorosulfonic acid polymer are polymerized The mass ratio of substance is 1.0:0.01, and the chemical structural formula of described side chain type sulfonated polyimide polymer is as follows:

[0049]

[0050] The preparation method of the side chain type sulfonated polyimide / perfluorosulfonic acid composite membrane comprises the following steps:

[0051] (1) Under the protection of argon, put 2.0mmol 2,2'-disulfonic acid benzidine, 55.0mL m-cresol and 1.3mL triethylamine into a 250mL three-port round bottom with a serpentine condenser In the flask, stir until the solid is dissolved; then add 4.0mmol 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane and 2.0mmol 2,2-bis(3-amino-4-hydroxy Phenyl)hexafluoropropane, stirred until the solid was dissolved; finally added 8.0mmol 1...

Embodiment 2

[0065] A side-chain type sulfonated polyimide / perfluorosulfonic acid composite membrane of the present invention has a thickness of 55 μm, and the side-chain type sulfonated polyimide polymer and perfluorosulfonic acid polymer are polymerized The mass ratio of substance is 1.0:0.01, and the chemical structural formula of described side chain type sulfonated polyimide polymer is as follows:

[0066]

[0067] The preparation method of the side chain type sulfonated polyimide / perfluorosulfonic acid composite membrane comprises the following steps:

[0068] (1) Under the protection of argon, put 4.0mmol 2,2'-disulfonic acid benzidine, 110.0mL m-cresol and 2.6mL triethylamine into a 500mL three-port round bottom with a serpentine condenser In the flask, stir until the solid is dissolved; then add 8.0mmol 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane and 4.0mmol 2,2-bis(3-amino-4-hydroxy Phenyl)hexafluoropropane, stirred until the solid was dissolved; finally added 16.0mmol...

Embodiment 3

[0072] A side-chain type sulfonated polyimide / perfluorosulfonic acid composite membrane of the present invention has a thickness of 35 μm, and the side-chain type sulfonated polyimide polymer and perfluorosulfonic acid polymer are polymerized The mass ratio of substance is 1.0:0.01, and the chemical structural formula of described side chain type sulfonated polyimide polymer is as follows:

[0073]

[0074] The preparation method of the side chain type sulfonated polyimide / perfluorosulfonic acid composite membrane comprises the following steps:

[0075] (1) Under the protection of argon, put 3.0mmol 2,2'-disulfonic acid benzidine, 85.0mL m-cresol and 2.0mL triethylamine into a 250mL three-port round bottom with a serpentine condenser In the flask, stir until the solid is dissolved; then add 6.0mmol 2,2-bis[4-(4-aminophenoxy)phenyl]hexafluoropropane and 3.0mmol 2,2-bis(3-amino-4-hydroxy Phenyl)hexafluoropropane, stirred until the solid was dissolved; finally added 12.0mmol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com