Crisp potato cake and preparation method thereof

A potato and potato starch technology, applied in the field of food processing, can solve the problem of less varieties of shortbread, achieve the effects of good hardness and crispness, delay aging, and enhance nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

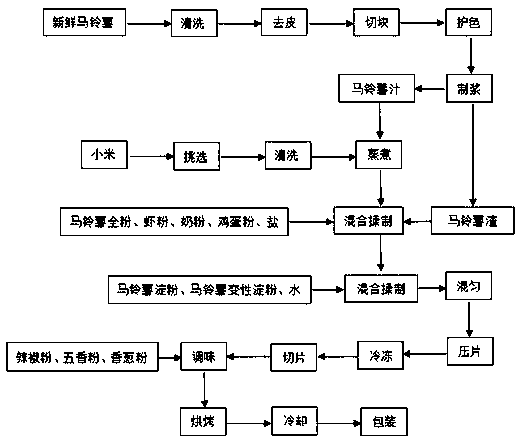

Image

Examples

Embodiment 1

[0027] 300 parts of potatoes, 100 parts of 1% vitamin C solution, 200 parts of 1% citric acid solution, 80 parts of millet, 100 parts of whole potato powder, 0.7 parts of shrimp powder, 0.7 parts of milk powder, 0.7 parts of egg powder, 2 parts of salt, potato starch 8 parts, 4 parts of modified potato starch, 10 parts of water, 1 part of chili powder, 4 parts of five-spice powder, and 2 parts of shallot powder.

[0028] Here’s how to prepare this potato crisp:

[0029] 1) Raw material processing: select fresh, disease-free and non-rotten potatoes, wash, peel, cut into 4 cm long, 2 cm wide, and 1 cm thick pieces, and put them into a mixed solution of vitamin C and citric acid to protect the color for 1 h Finally, crush it with a beater and filter to obtain potato juice (about 40%) and potato residue (about 60%) respectively.

[0030] 2) Selecting materials for steaming: Select high-quality millet with plump grains and bright color, add potato juice (all potato juice obtained ...

Embodiment 2

[0039] 400 parts of potatoes, 150 parts of 1% vitamin C solution, 250 parts of 1% citric acid solution, 90 parts of millet, 150 parts of whole potato powder, 1 part of shrimp powder, 1 part of milk powder, 1 part of egg powder, 3 parts of salt, potato starch 9 parts, 6 parts of potato modified starch, 15 parts of water, 2 parts of chili powder, 5 parts of five-spice powder, and 3 parts of shallot powder.

[0040] Here’s how to prepare this potato crisp:

[0041] 1) Raw material processing: select fresh, disease-free and non-rotten potatoes, wash, peel, cut into 4 cm long, 2 cm wide, and 1 cm thick pieces, and put them into a mixed solution of vitamin C and citric acid to protect the color for 1 h Finally, crush it with a beater and filter to obtain potato juice (about 40%) and potato residue (about 60%) respectively.

[0042] 2) Selection of ingredients for steaming: Select high-quality millet with plump grains and bright color, add potato juice (all potato juice obtained aft...

Embodiment 3

[0051] 500 parts of potatoes, 200 parts of 1% vitamin C solution, 300 parts of 1% citric acid solution, 100 parts of millet, 200 parts of whole potato powder, 1.2 parts of shrimp powder, 1.2 parts of milk powder, 1.2 parts of egg powder, 5 parts of salt, potato starch 10 parts, 7 parts of modified potato starch, 20 parts of water, 3 parts of chili powder, 5 parts of five-spice powder, and 4 parts of shallot powder.

[0052]Here’s how to prepare this potato crisp:

[0053] 1) Raw material processing: select fresh, disease-free and non-rotten potatoes, wash, peel, cut into 4 cm long, 2 cm wide, and 1 cm thick pieces, and put them into a mixed solution of vitamin C and citric acid to protect the color for 1 h Finally, crush it with a beater and filter to obtain potato juice (about 40%) and potato residue (about 60%) respectively.

[0054] 2) Selecting materials for steaming: Select high-quality millet with plump grains and bright color, add potato juice (all potato juice obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com