Method for preparing hierarchical porous isomorphous substitution Ga-ZSM-5 molecular sieve catalyst

A technology of isomorphic substitution and molecular sieve, which is applied in the application field of conversion of benzene and methanol into toluene and xylene, can solve the problems of poor service life of the catalyst, affecting the diffusion performance of the pores, and reducing the utilization rate of methanol, etc. Toluene selectivity, high catalyst stability, and the effect of suppressing ethylbenzene by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

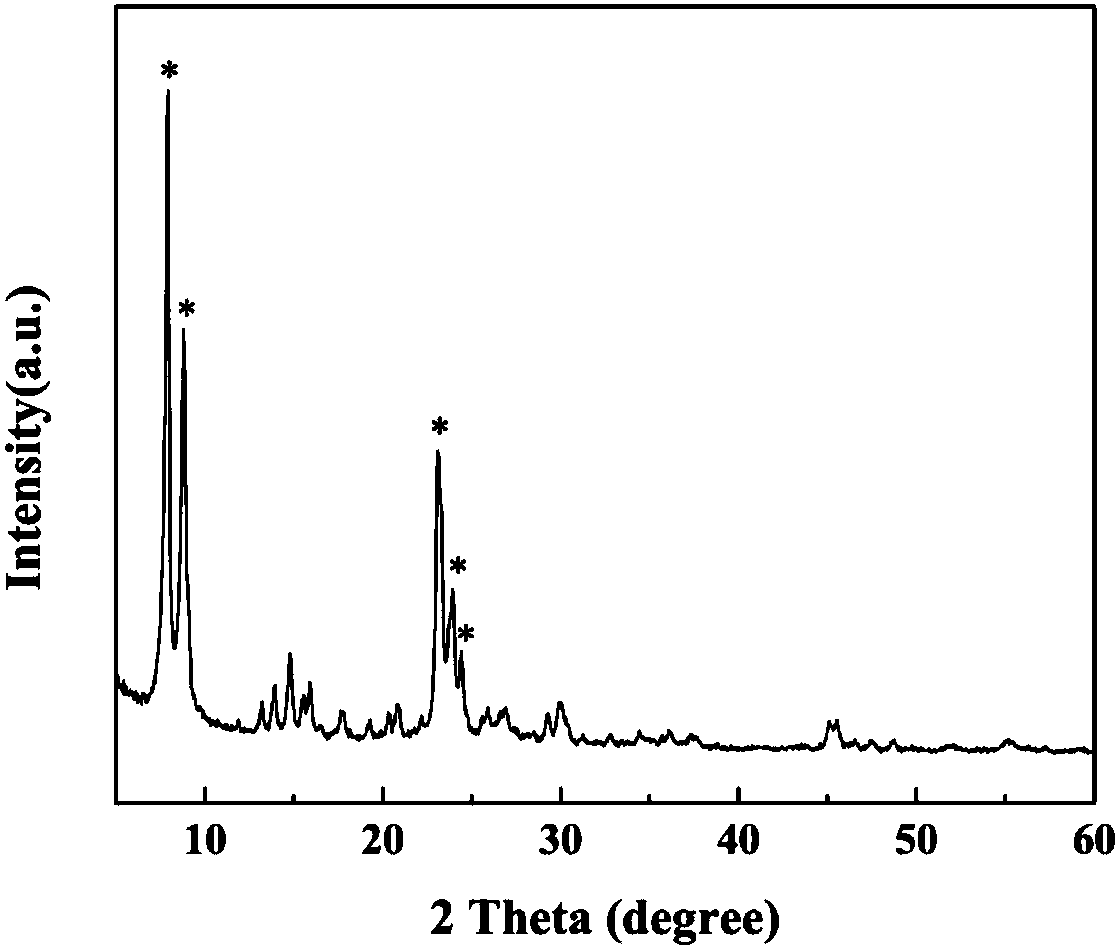

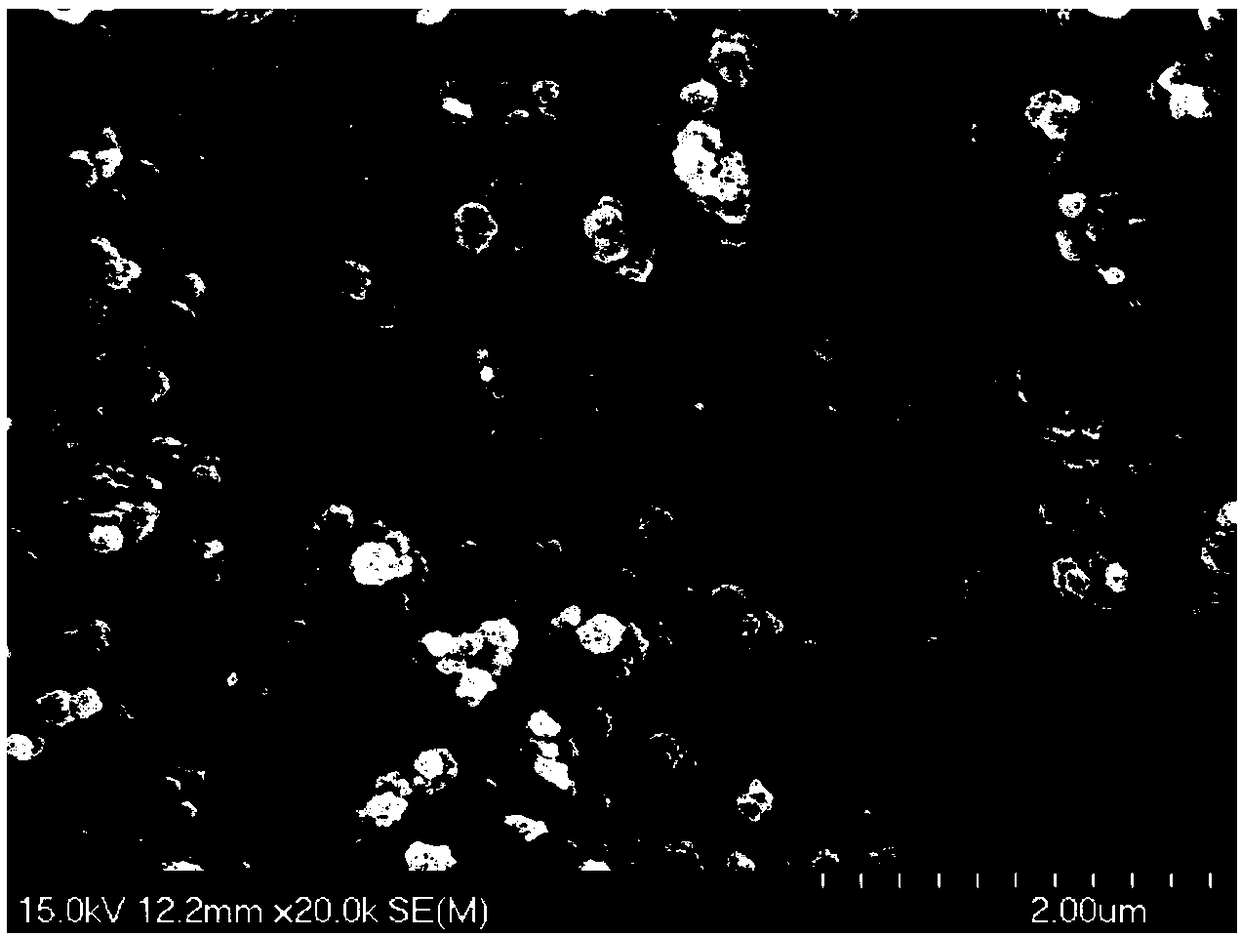

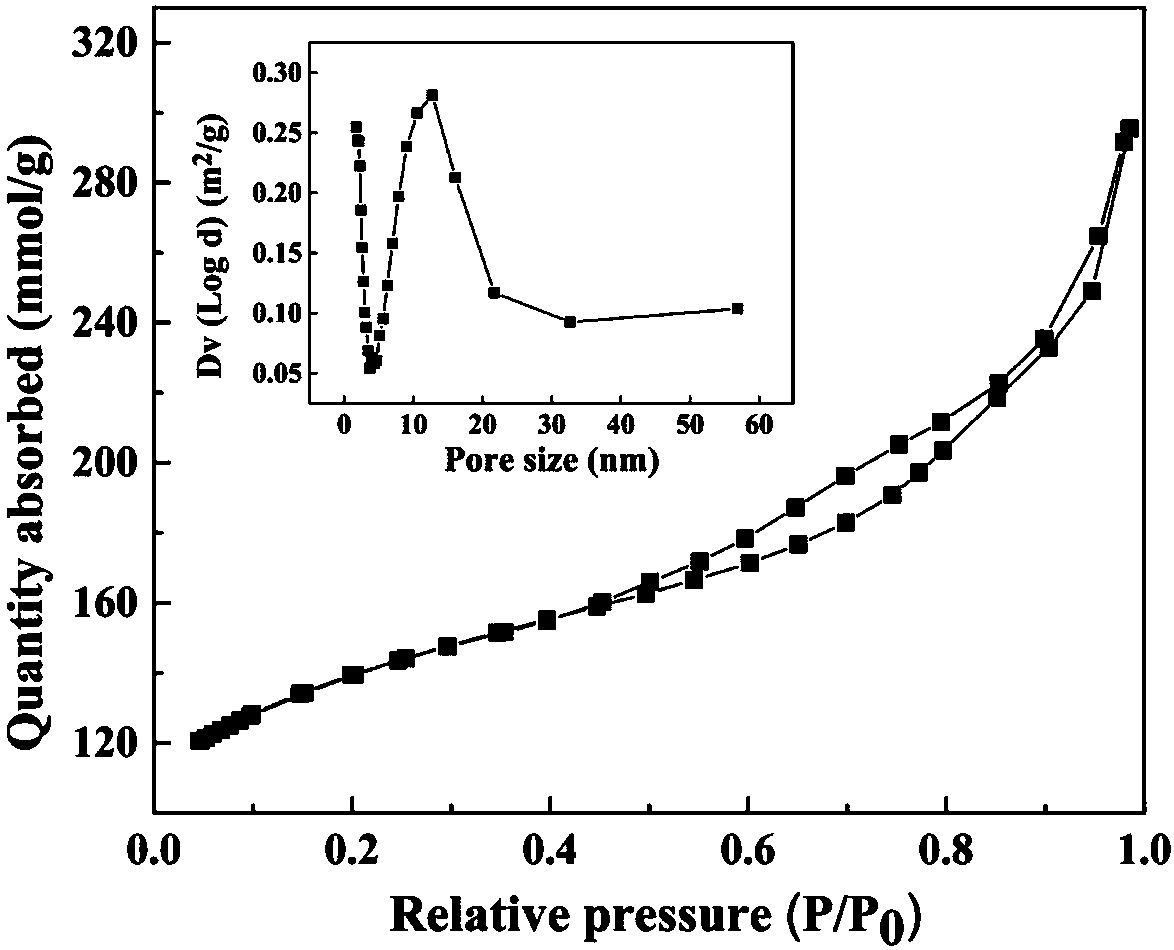

[0031] Example 1: 0.0680g aluminum isopropoxide, 12.0g tetrapropyl ammonium hydroxide aqueous solution (25wt%), 13.2ml tetraethyl orthosilicate, 1.2g hexadecyltrimethoxysilane (85wt%) and 50ml Ethanol was mixed in a beaker and stirred at 20°C until a gel was formed; the gel was dried at 20°C for 24h, and then the gel was transferred to a PTFE liner (A) with a volume of 50ml, and another volume of 250ml was taken PTFE liner (B) and add 40ml of deionized water to it, then transfer the above-mentioned liner (A) to the liner (B), at this time the deionized water is between the two liners; Transfer the combined lining to a 250ml stainless steel hydrothermal kettle, crystallize at 170°C for 72h; filter and wash, dry at 100°C for 4h, and roast at 550°C for 10h; press the calcined catalyst and crush it , sieve, and take a catalyst with a particle size of 20 to 40 meshes to obtain a hierarchically porous ZSM-5 molecular sieve (Si / Al=180) with 0% Ga substitution.

Embodiment 2

[0032] Embodiment 2: with 0.0340g aluminum isopropoxide, 0.0421g gallium nitrate, 12.0g tetrapropyl ammonium hydroxide aqueous solution (25wt%), 13.2ml orthosilicate ethyl ester, 1.2g hexadecyltrimethoxysilane ( 85wt%) and 50ml of ethanol were mixed in a beaker and stirred at 20°C until a gel was formed; the gel was dried at 20°C for 24h, and then the gel was transferred to a polytetrafluoroethylene liner (A) with a volume of 50ml, Take another PTFE liner (B) with a volume of 250ml and add 40ml of deionized water to it, then transfer the above-mentioned liner (A) to the liner (B), at this time, the deionized water is located in the two inner between the linings; transfer the combined lining to a 250ml stainless steel hydrothermal kettle, crystallize at 180°C for 72h; filter and wash, dry at 100°C for 4h, and roast at 550°C for 10h; the calcined catalyst Perform tableting, crushing, and sieving, and take a catalyst with a particle size of 20 to 40 meshes to obtain a hierarchica...

Embodiment 3

[0033] Embodiment 3: with 0.0204g aluminum isopropoxide, 0.0589g gallium nitrate, 12.0g tetrapropyl ammonium hydroxide aqueous solution (25wt%), 13.2ml orthosilicate ethyl ester, 1.2g hexadecyltrimethoxysilane ( 85wt%) and 50ml of ethanol were mixed in a beaker and stirred at 20°C until a gel was formed; the gel was dried at 20°C for 24h, and then the gel was transferred to a polytetrafluoroethylene liner (A) with a volume of 50ml, Take another PTFE liner (B) with a volume of 250ml and add 40ml of deionized water to it, then transfer the above-mentioned liner (A) to the liner (B), at this time, the deionized water is located in the two inner between the linings; transfer the combined lining to a 250ml stainless steel hydrothermal kettle, crystallize at 180°C for 72h; filter and wash, dry at 100°C for 4h, and roast at 550°C for 10h; the calcined catalyst Perform tableting, crushing, and sieving, and take a catalyst with a particle size of 20 to 40 meshes to obtain a hierarchica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com