High-temperature and low-thermal conductivity bismuth oxide-based thermal barrier coating material and preparation method thereof

A technology of thermal barrier coating and low thermal conductivity, which is applied in the field of hafnium oxide-based thermal barrier coating materials and its preparation, can solve the problems of thermal conductivity improvement, achieve high-temperature phase stability, simple synthesis method, good barrier The effect of thermal radiation heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment one: HfO 2 Preparation of thermal barrier coating materials.

[0031] (1) Take nanoscale powder HfOCl 2 ·8H 2 O, heated in a water bath at 80°C, and stirred for five minutes until clear and transparent. Add citric acid and stir magnetically for half an hour until viscous sol is formed. Among them, Hf 4+ The molar ratio of ions and citric acid is 1:2.

[0032] (2) Heat the sol in a drying oven at 80°C for 12 hours to form a xerogel. Heat the dry gel in a box furnace at 1000°C for two hours, and grind it in an agate mortar to obtain a fine powder.

[0033] (3) Cold press the above fine powder into a diameter left and right discs. After heating up to 1000°C at a heating rate of 2°C / min, the temperature was raised to 1500°C at a heating rate of 1.33°C / min, kept for 5 hours and then cooled to 25°C with the furnace to obtain HfO 2 blocks.

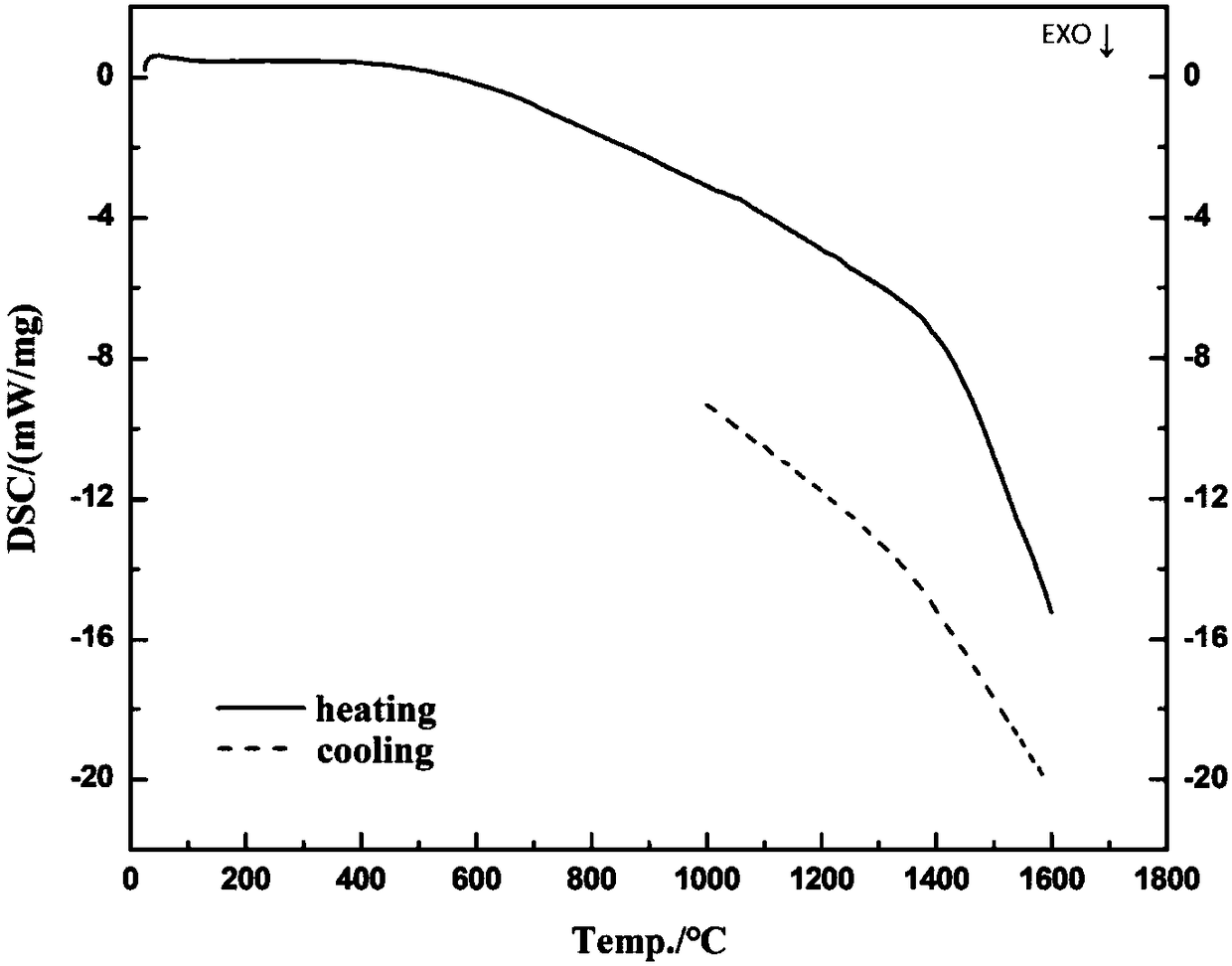

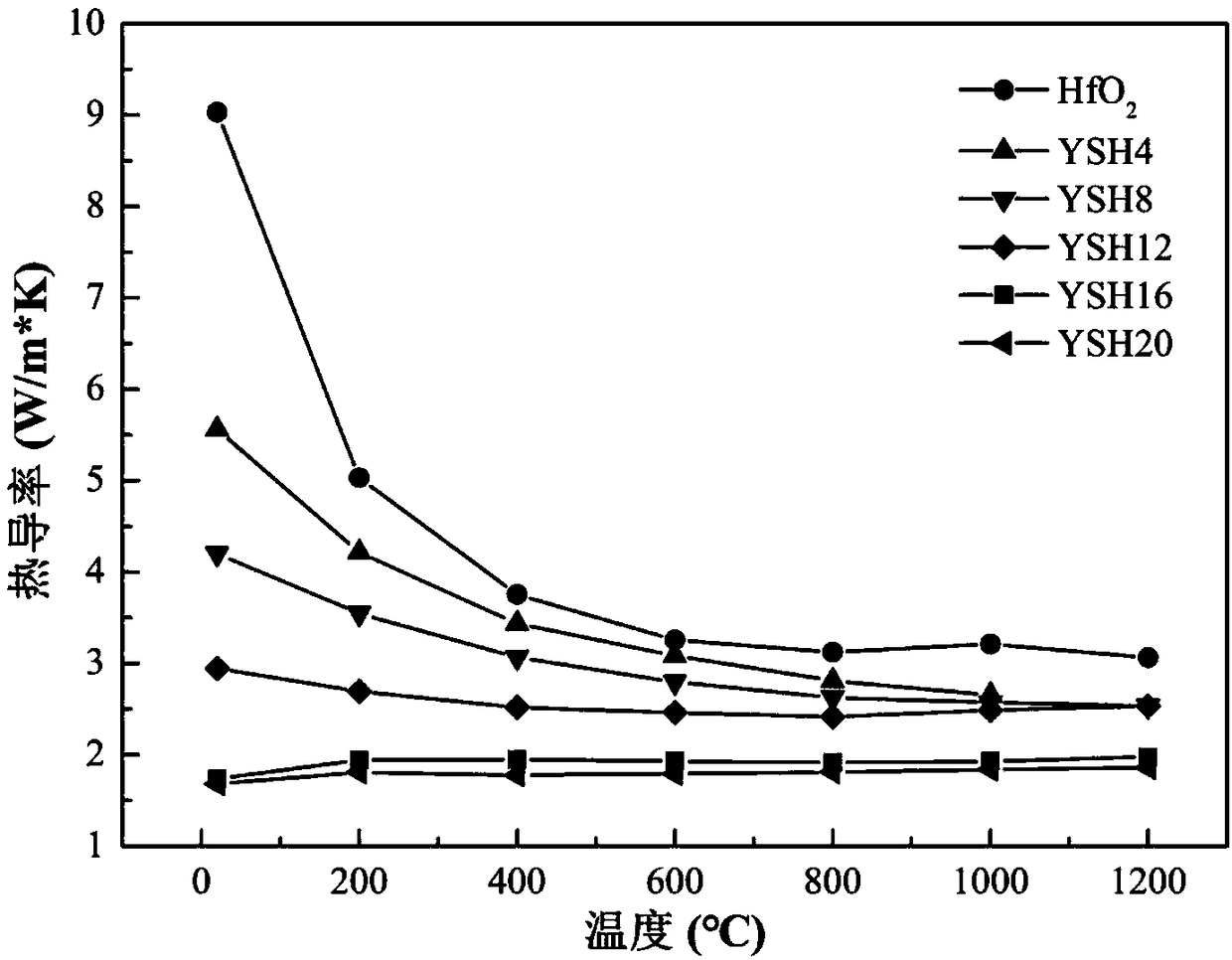

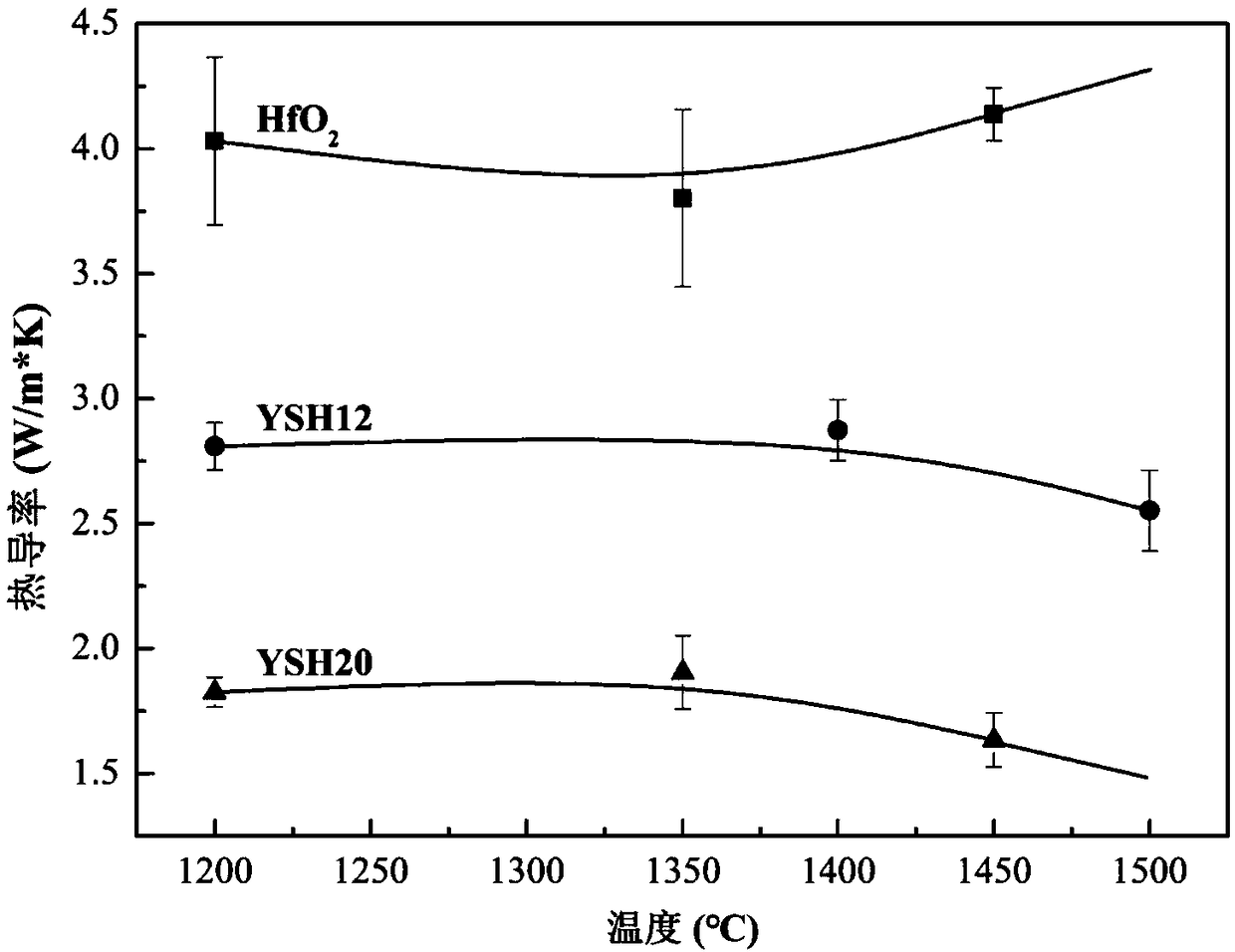

[0034] XRD shows HfO 2 The bulk material is monoclinic phase, and it is found that there is no microcrack in the s...

Embodiment 2

[0035] Example 2: Preparation of YSH4 thermal barrier coating material.

[0036] (1)Y 2 o 3 Dissolve in 70% concentrated nitric acid, heat in a water bath at 80°C, and stir magnetically until completely transparent. Add stoichiometric ratio of HfOCl 2 ·8H 2 O, continue to stir for five minutes until clear and transparent. Adding citric acid makes the cation (Hf 4+ with Y 3+ ) and citric acid in a molar ratio of 1:2, magnetically stirred for half an hour until viscous sol was formed.

[0037] (2) Heat the sol in a drying oven at 80°C for 12 hours to form a xerogel. Heat the dry gel in a box furnace at 1000°C for two hours, and grind it in an agate mortar to obtain a fine powder.

[0038] (3) Cold press the above fine powder into a diameter left and right discs. After heating up to 1000°C at a heating rate of 2°C / min, the temperature was raised to 1500°C at a heating rate of 1.33°C / min, held for 5 hours, and then cooled to 25°C with the furnace to obtain YSH4 blocks.

...

example 3

[0041] Example 3: Preparation of YSH8 and YSH12 thermal barrier coating materials.

[0042] (1)Y 2 o 3 , HfO 2 Weigh with stoichiometric ratio YSH8, add alcohol to the mixed powder, mix and grind for 8 hours, dry at 80°C for 12 hours, sinter at 1600°C for 5 hours, and cool in the furnace to room temperature.

[0043] (2) Continue to add alcohol to the powder after cooling in the furnace to grind for 8 hours, ball mill and dry the ground powder (80°C for 12 hours), then manually grind, and pass through a 200-mesh sieve to obtain a fine powder.

[0044] (3) Cold press the above fine powder into a diameter left and right discs. The temperature was raised to 1000°C at a heating rate of 2°C / min, and then to 1600°C at a heating rate of 1.33°C / min, kept for 5 hours and then cooled to room temperature 25°C with the furnace to obtain YSH8 blocks.

[0045] Change the stoichiometric ratio to YSH12, and prepare YSH12 blocks according to the same method steps and conditions as above....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com