A kind of efficient peeling method of bitter almond

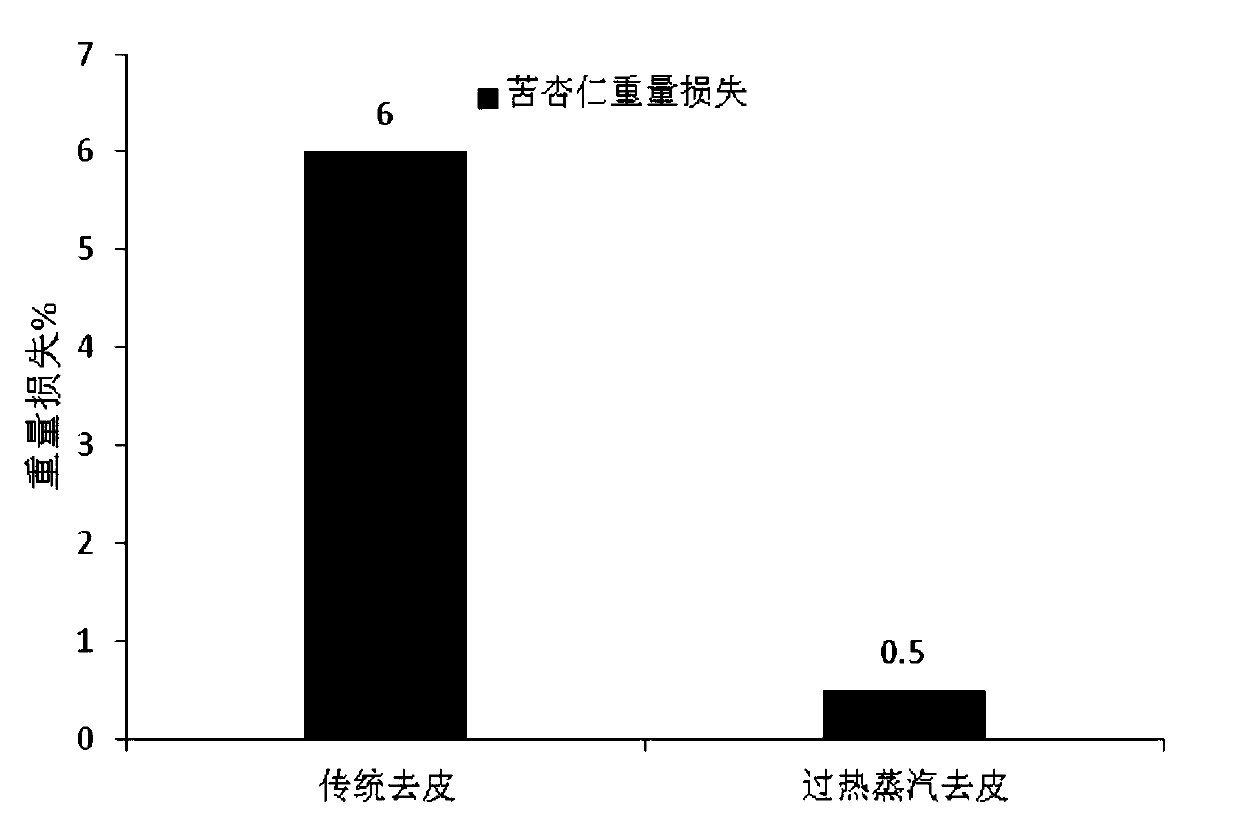

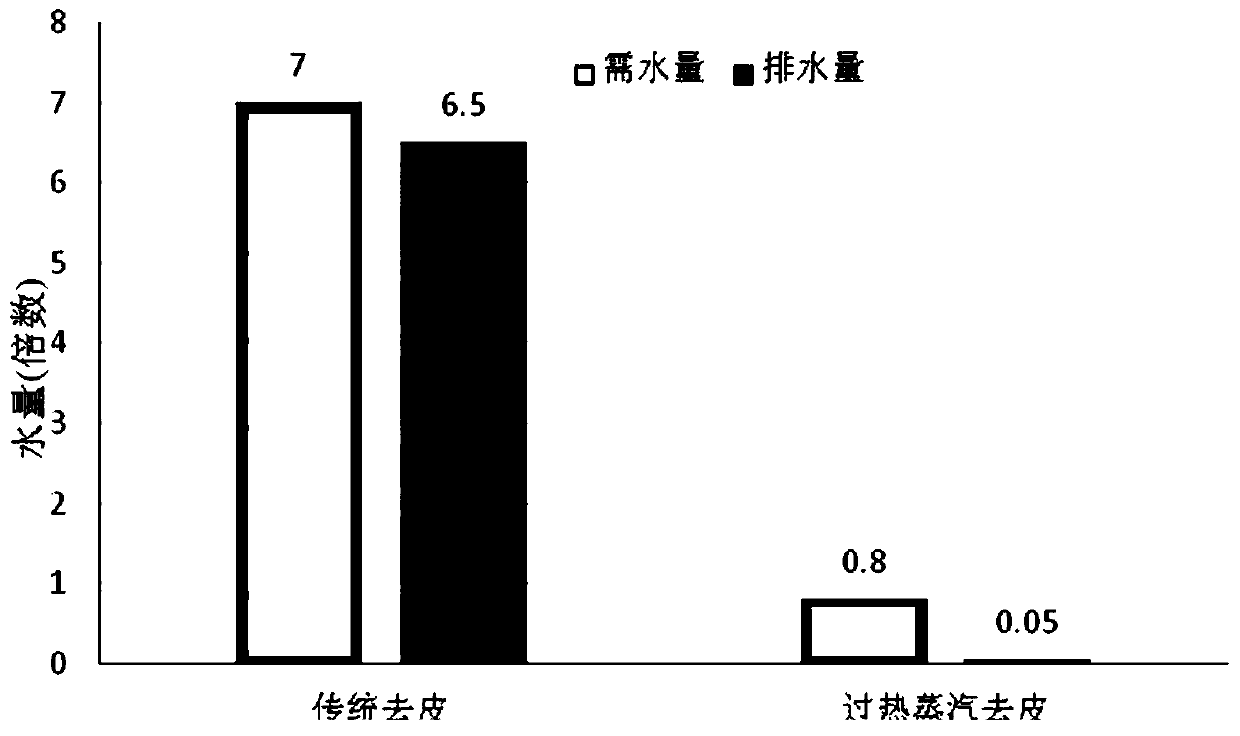

A bitter almond, high-efficiency technology, applied in the field of high-efficiency peeling of bitter almonds, can solve the problems of large water consumption, waste water discharge, peeling water pollution, etc., and achieve the effects of saving water, reducing sewage discharge, and reducing heat energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described in conjunction with the accompanying drawings and experiments.

[0030] The technological process of the efficient peeling method for bitter almonds of the present invention is:

[0031] Bitter almond selection, removal of impurities → pre-freezing treatment → rinsing → superheated steam treatment → rubbing and peeling

[0032] According to this technical process, the peeling of bitter almonds is specifically realized by the following methods:

[0033] (1) Screen bitter almonds, select bitter almonds with good appearance and complete grains, remove moldy and incomplete bitter almonds, and place the screened bitter almonds in a low temperature environment of -40°C to 0°C for a period of pre-freezing time;

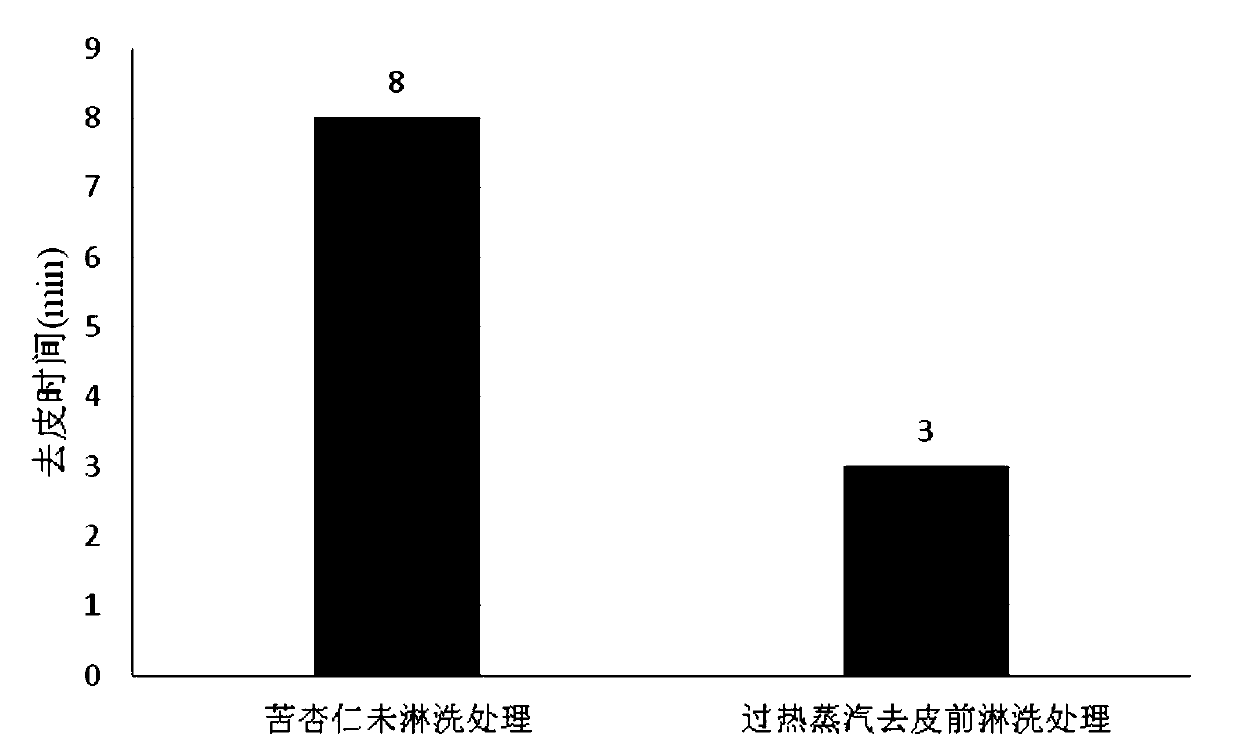

[0034] (2) Place the pre-frozen bitter almonds in a screen container with grid gaps, put the bitter almonds into water together with the container, and rinse the screen container filled with b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com