Method for preparing titanium alloy bone implant with surface bioactivity through synchronous wire-powder laser deposition

A technology of laser deposition and biological activity, applied in prosthetics, drug delivery, tissue regeneration, etc., can solve the problems of easy peeling off of biological coatings and inability to realize personalized customization, so as to increase the area, ensure layer-by-layer growth, Effect of reducing crack tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

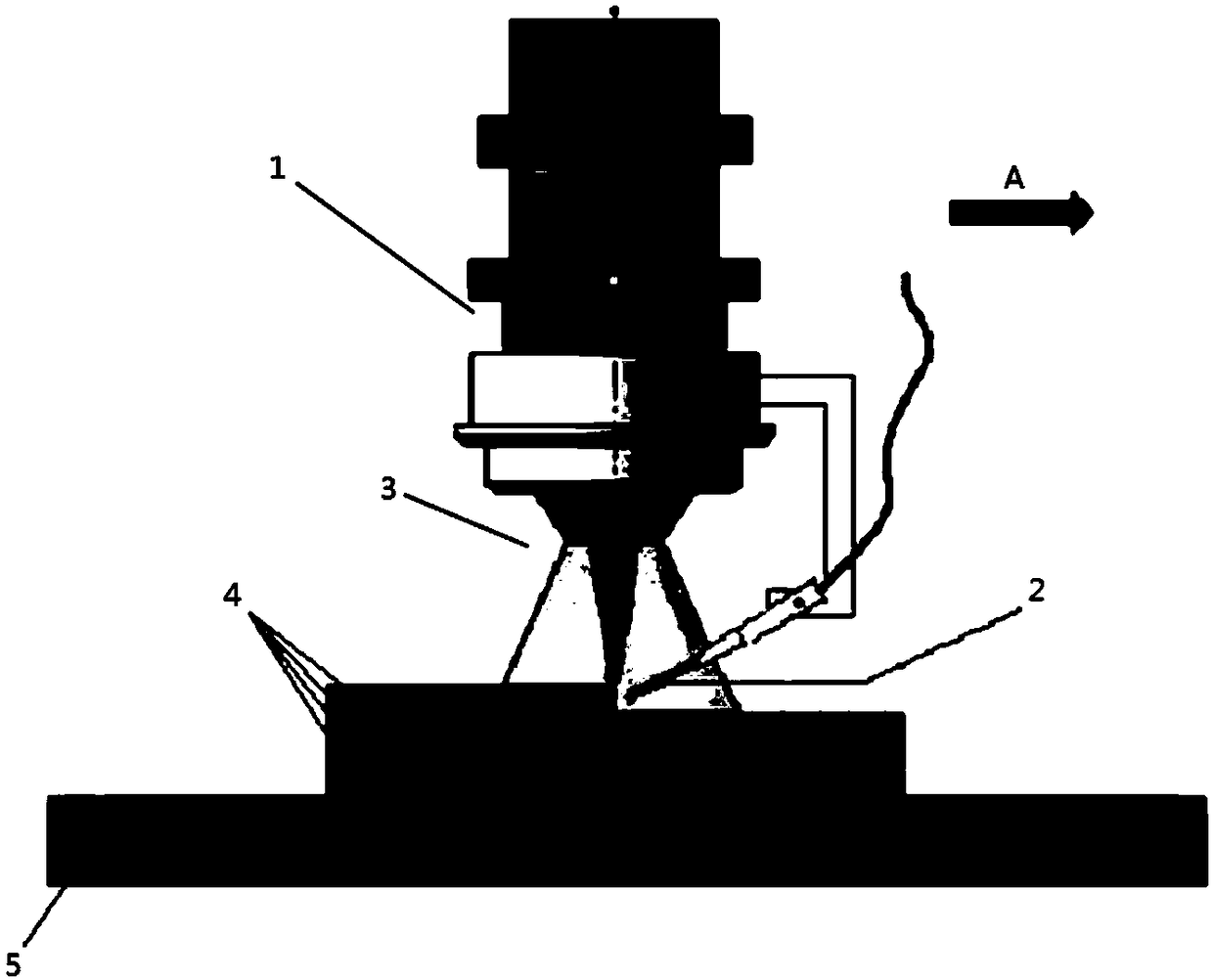

[0023] Specific embodiment 1: The method for preparing surface bioactive titanium alloy bone implants by synchronous laser deposition of silk powder in this embodiment includes the following steps:

[0024] 1. Preparation of bone implant matrix:

[0025] The titanium alloy wire is fed into the laser molten pool area by the wire feeder. The titanium alloy wire is gradually melted and resolidified into a titanium alloy deposition layer as the molten pool moves, and then on the first titanium alloy deposition layer Prepare the titanium alloy deposition layer again, repeat the process, prepare the titanium alloy deposition layer layer by layer, which is the titanium alloy matrix;

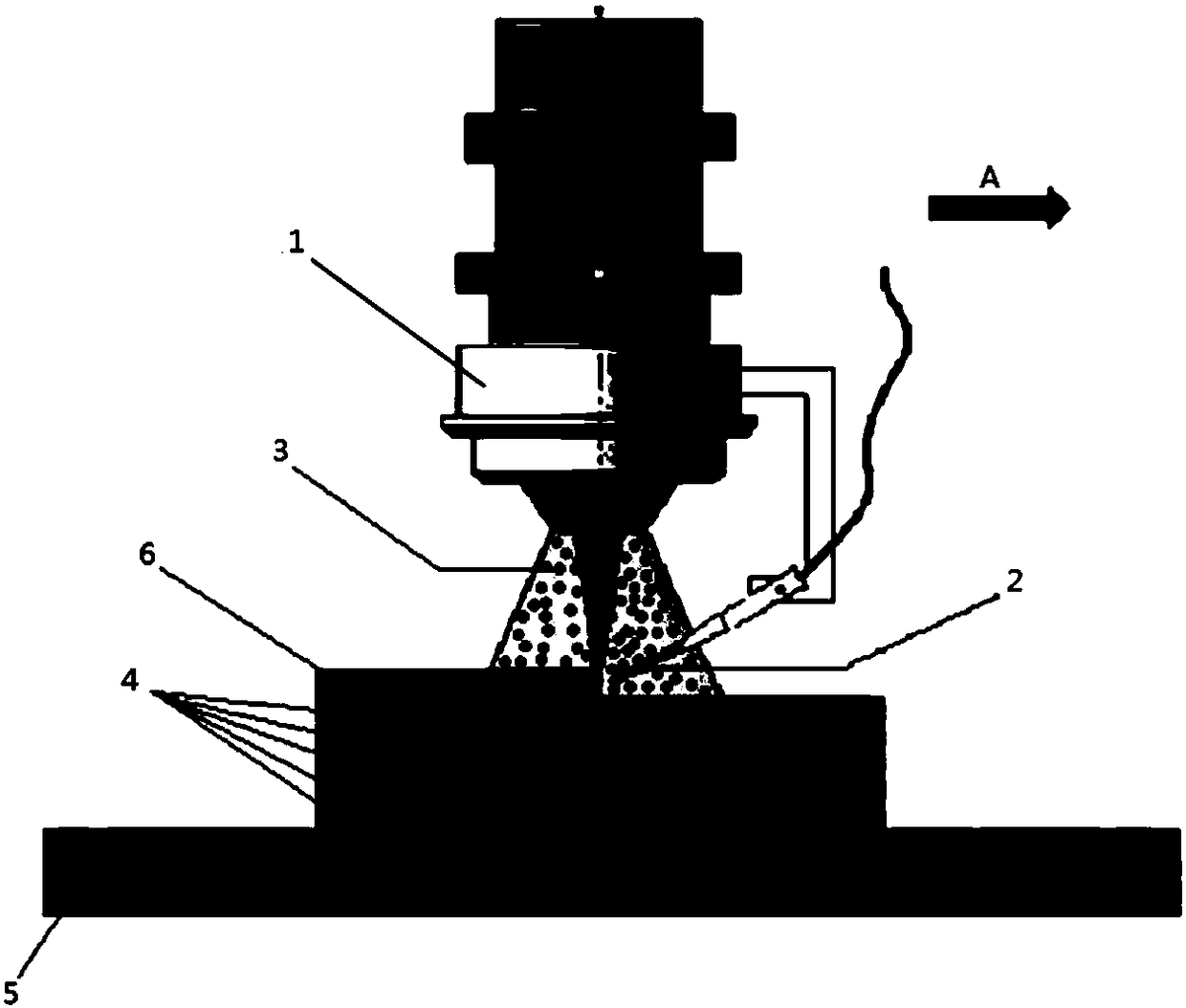

[0026] 2. Preparation of biologically active surface deposits:

[0027] While continuing to feed the titanium alloy wire along the axis, the hydroxyapatite powder is fed coaxially, and the hydroxyapatite-titanium composite layer is formed by laser deposition on the surface of the titanium alloy matrix to obtain...

specific Embodiment approach 2

[0030] Embodiment 2: The difference between this embodiment and the first embodiment is: in step 1, after the first titanium alloy deposition layer is completed, the laser power of each titanium alloy deposition layer is higher than that of the first titanium alloy deposition layer. The layer is reduced by 100-300W. Others are the same as the first embodiment.

specific Embodiment approach 3

[0031] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the scanning speed in step two is 0.02-0.04 m / min. Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com