Method for preparing porous silicon adsorption material by using low-grade diatomite and porous silicon adsorption material

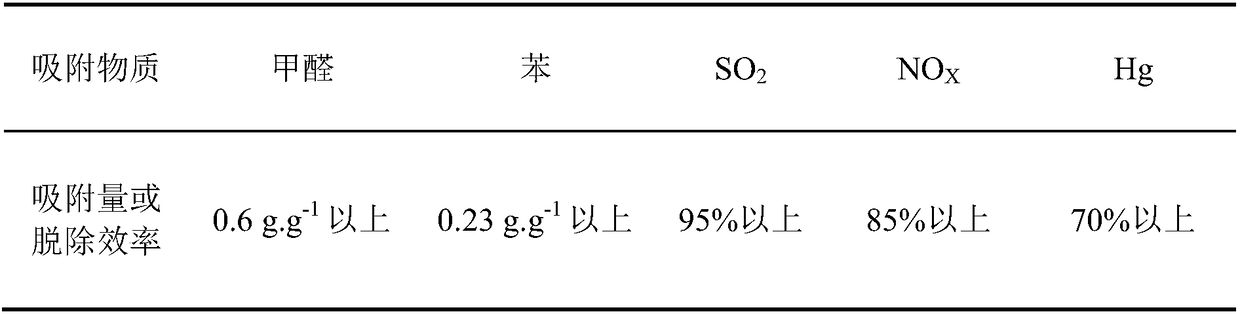

An adsorption material, diatomite technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as insufficient adsorption performance of volatile organic compounds, complicated preparation technology, and long process flow , to achieve the effect of high added value of products, simple preparation technology and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

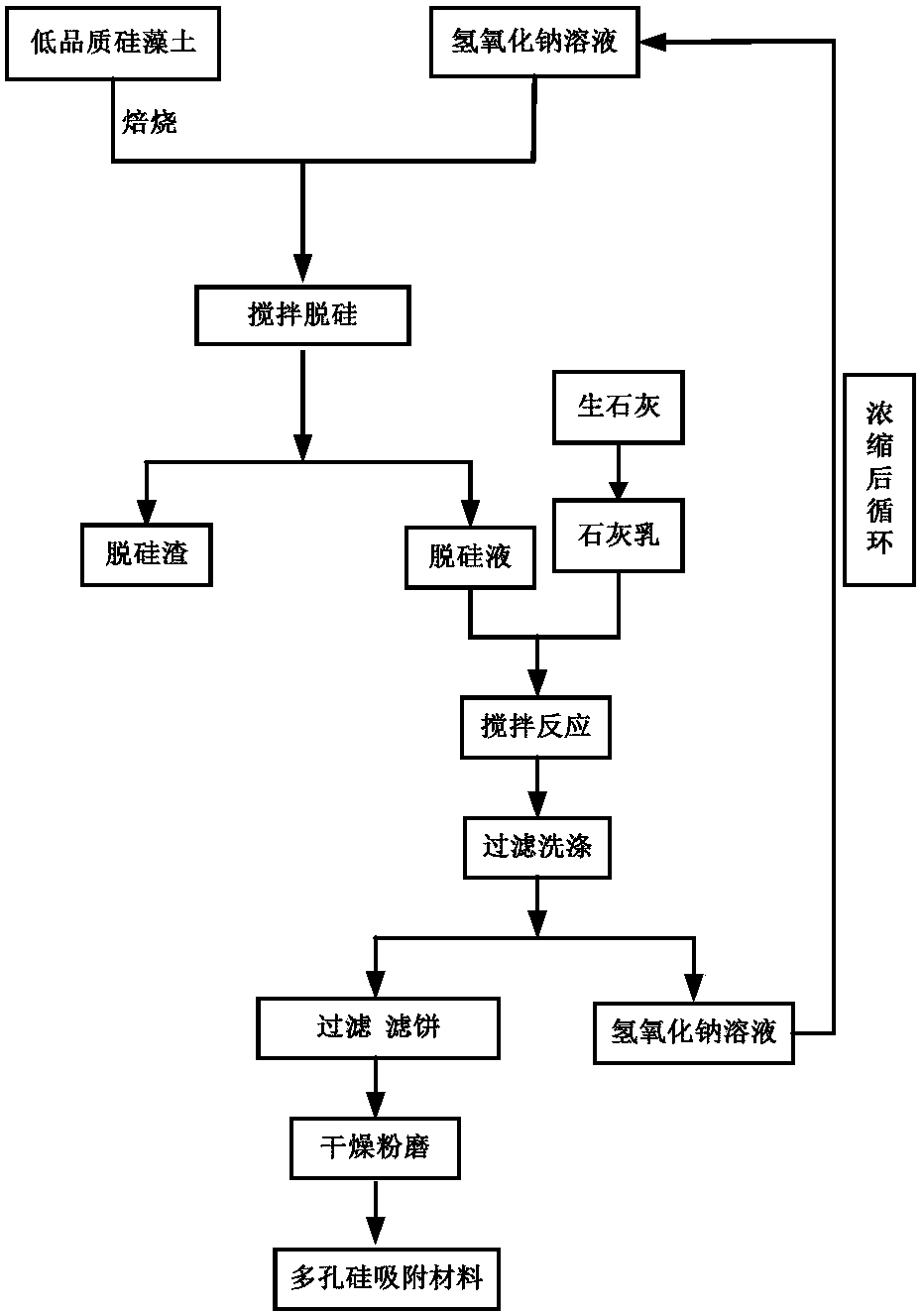

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of method that utilizes low-grade diatomite to prepare porous silicon adsorption material, it comprises the following steps: 1) preparation roasting diatomite; 2) alkali leaching desiliconization; 3) filtration, washing; 4) preparation high Active milk of lime; 5) make porous silicon adsorption material; wherein,

[0024] 1) Preparation of roasted diatomite: SiO 2 10Kg of low-grade diatomite with a mass percentage of 68% was crushed and ground, roasted at 250°C for 1.5h to remove organic matter, and then sieved to obtain roasted diatomite with a particle size greater than 325 meshes;

[0025] 2) Alkali leaching desiliconization: put the roasted diatomite and 20% sodium hydroxide solution in a reaction kettle, mechanically stir and mix, and carry out alkali leaching desiliconization reaction. The desiliconization reaction temperature is 80 ° C. The silicon reaction time is 3 hours, and the suspension slurry system is obtained; wherein, the SiO in th...

Embodiment 2

[0030] Embodiment 2: A kind of method that utilizes low-grade diatomite to prepare porous silicon adsorption material, it comprises the following steps: 1) preparation roasting diatomite; 2) alkali leaching desiliconization; 3) filtration, washing; 4) preparation high Active milk of lime; 5) make porous silicon adsorption material; wherein,

[0031] 1) Preparation of roasted diatomite: SiO 2 10Kg of low-grade diatomite with a content of 72%wt was crushed and ground, roasted at 300°C for 3 hours to remove organic matter, and then sieved to obtain roasted diatomite with a particle size greater than 325 mesh;

[0032] 2) Alkali leaching desiliconization: mix the roasted diatomite and 5% sodium hydroxide solution evenly, place it in a reaction kettle, stir it mechanically, and carry out alkali leaching desiliconization reaction. During the desilication reaction process Continuous mechanical stirring to keep the desilication reaction uniform. The desiliconization reaction tempera...

Embodiment 3

[0037] Embodiment 3: A kind of method that utilizes low-grade diatomite to prepare porous silicon adsorption material, it comprises the following steps: 1) preparation roasting diatomite; 2) alkali leaching desiliconization; 3) filtration, washing; 4) preparation high Active milk of lime; 5) make porous silicon adsorption material; wherein,

[0038] 1) Preparation of roasted diatomite: SiO 2 10Kg of low-grade diatomite with a content of 70%wt was crushed and ground, roasted at 200°C for 1 hour to remove organic matter, and then sieved to obtain roasted diatomite with a particle size greater than 325 mesh;

[0039] 2) Alkali leaching desiliconization: the roasted diatomite and the sodium hydroxide solution with a mass concentration of 30% are mixed evenly and then placed in a reaction kettle, mechanically stirred, and alkali leaching desilication reaction is carried out. During the desilication reaction process Continuous mechanical stirring to keep the desilication reaction u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com