Application of cadmium sulfide two-dimensional nano-sheet in hydrogen and oxygen production by acoustic wave assisted photolysis of water

A two-dimensional nano, cadmium sulfide technology, applied in the production of cadmium sulfide, oxygen/ozone/oxide/hydroxide, hydrogen, etc., can solve the problem of low hydrogen and oxygen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Synthesis of two-dimensional CdS nanosheet hybrid precursor

[0026] Weigh 0.4mmol of anhydrous cadmium chloride and 2mmol of sublimated sulfur powder, disperse in diethylenetriamine solution with a concentration of 9.12mol / L, stir at room temperature for 30min to make the precursors evenly mixed, then transfer to the reaction kettle, cover and seal , put it into a stainless steel sleeve and lock it tightly, raise the temperature to 80°C, and keep it warm for 48h; the obtained yellow powder was washed 4-5 times with deionized water and absolute ethanol respectively, and then transferred to a vacuum oven at 60°C for 12h to obtain a hybrid Precursor samples.

Embodiment 2

[0027] Example 2 Synthesis of two-dimensional CdS nanosheets

[0028] Take 40 mg of the hybrid precursor sample obtained in Example 1, disperse it in 50 ml of deionized water, disperse it ultrasonically for 2 minutes to dissolve the powder, and reflux it under stirring at 80°C for 12 hours to remove all the organic matter in the hybrid precursor. Wash with deionized water and absolute ethanol three times respectively, and transfer to a 60°C vacuum oven to dry for 6 hours. The obtained sample is labeled as CdS-NS.

Embodiment 3

[0029] Example 3 Structural Characterization

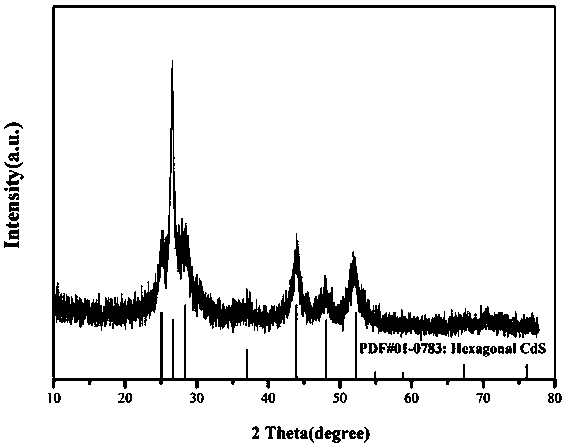

[0030] The CdS-NS synthesized in Example 2 is scanned by an X-ray diffractometer, and the results are shown in figure 1 . Depend on figure 1 It can be determined that it is a hexagonal wurtzite CdS crystal.

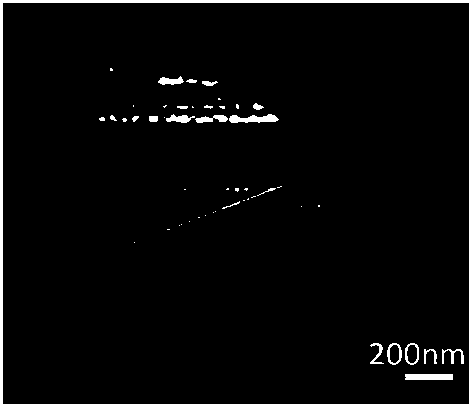

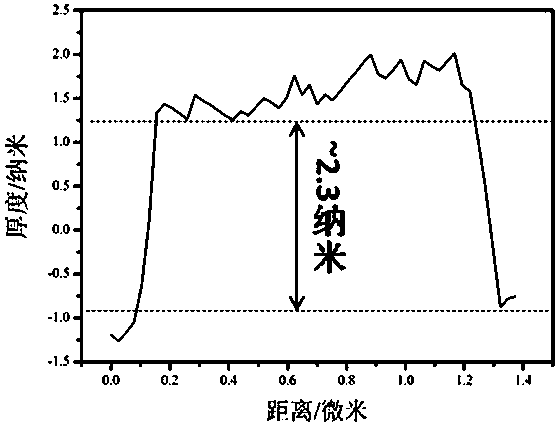

[0031] The CdS-NS synthesized in Example 2 was observed with an atomic force microscope, and the results are shown in figure 2 , 3 . Depend on figure 2 , 3 It can be seen that the obtained CdS is a two-dimensional nanosheet with an average thickness of about 1-3 nm and a length of not less than 800 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com