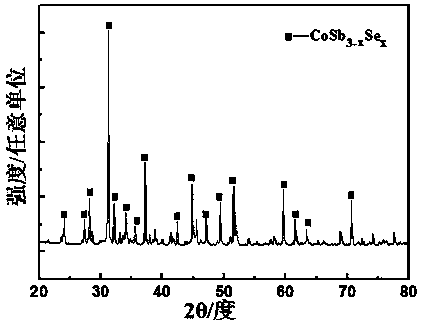

Preparation method of Se doped skutterudite thermoelectric material

A technology of thermoelectric material and skutterudite, which is applied in the manufacture/processing of thermoelectric devices, and lead wire materials of thermoelectric device nodes, etc., can solve the problems of uneven doping of skutterudite thermoelectric materials and deviation of thermoelectric properties of thermoelectric materials, etc. Achieve the effect of excellent thermoelectric performance, excellent thermoelectric performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

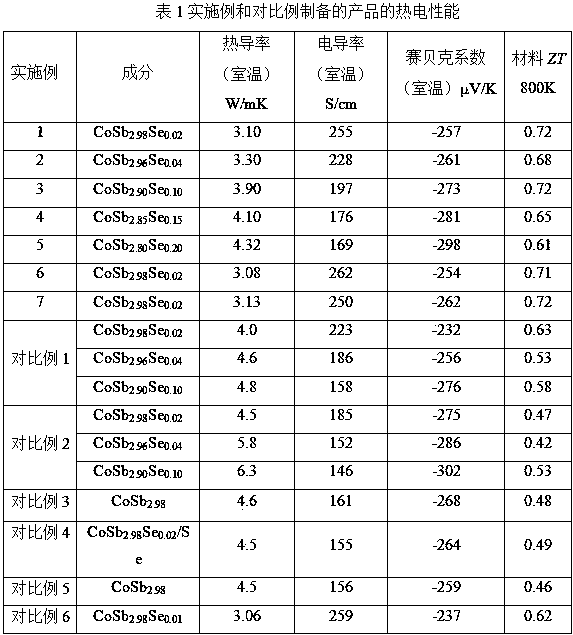

Embodiment 1

[0029] Using high-purity (99.99%) cobalt powder (Co) and antimony powder (Sb) as raw materials, the stoichiometric ratio is 1:2.98, and the Sb-deficient CoSb is prepared by melting-annealing process. 3-x Thermoelectric material powder, x=0.02. The melt annealing process is as follows: mix cobalt powder (Co) and antimony powder (Sb), heat up to 1040°C and melt for 24 hours, then anneal the molten metal at 620°C for 96 hours, and grind the annealed product to obtain Sb-deficient CoSb 3-x Thermoelectric material powder.

[0030] The resulting Sb-deficient CoSb 3-xThe thermoelectric material powder was put into a mortar and ground to 80 μm, and the obtained powder was evenly spread in a graphite crucible. Take a quartz tube, put a selenium block into the bottom of the quartz tube, then put a graphite crucible on top of the selenium block, and vacuum seal the quartz tube. After fusing, the vacuum degree in the quartz tube is 5Pa. Place the vacuum-sealed quartz tube vertically i...

Embodiment 2

[0035] Using high-purity (99.99%) cobalt powder (Co) and antimony powder (Sb) as raw materials, the stoichiometric ratio is 1:2.96, and the Sb-deficient CoSb is prepared by melting-annealing process. 3-x Thermoelectric material powder, x=0.04. The melt annealing process is as follows: mix cobalt powder (Co) and antimony powder (Sb), heat up to 1040°C and melt for 24 hours, then anneal the molten metal at 620°C for 96 hours, and grind the annealed product to obtain Sb-deficient CoSb 3-x Thermoelectric material powder.

[0036] The resulting Sb-deficient CoSb 3-x The thermoelectric material powder was put into a mortar and ground to 150 μm, and the obtained powder was evenly spread in a graphite crucible. Take a quartz tube, put a selenium block into the bottom of the quartz tube, then put a graphite crucible on top of the selenium block, and vacuum seal the quartz tube. After fusing, the vacuum degree in the quartz tube is 10Pa. Place the vacuum-sealed quartz tube verticall...

Embodiment 3

[0040] Using high-purity (99.99%) cobalt powder (Co) and antimony powder (Sb) as raw materials, according to the stoichiometric ratio of 1:2.9, the Sb-deficient CoSb was prepared by melting-annealing process 3-x Thermoelectric material powder, x=0.1. The melt annealing process is as follows: mix cobalt powder (Co) and antimony powder (Sb), heat up to 1040°C and melt for 24 hours, then anneal the molten metal at 620°C for 96 hours, and grind the annealed product to obtain Sb-deficient CoSb 3-x Thermoelectric material powder.

[0041] The resulting Sb-deficient CoSb 3-x The thermoelectric material powder was put into a mortar and ground to 200 μm, and the obtained powder was evenly spread in a graphite crucible. Take a quartz tube, put a selenium block into the bottom of the quartz tube, then put a graphite crucible on top of the selenium block, and vacuum seal the quartz tube. After fusing, the vacuum degree in the quartz tube is 8Pa. Place the vacuum-sealed quartz tube ver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com