Condensation reaction polysiloxane composition and cured product

A condensation reaction, polysiloxane technology, applied in the field of condensation reaction type polysiloxane compositions and cured products, can solve the problems of insufficient heat resistance, curing obstacles of platinum catalysts, etc. The effect of good heat resistance and transparency, and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

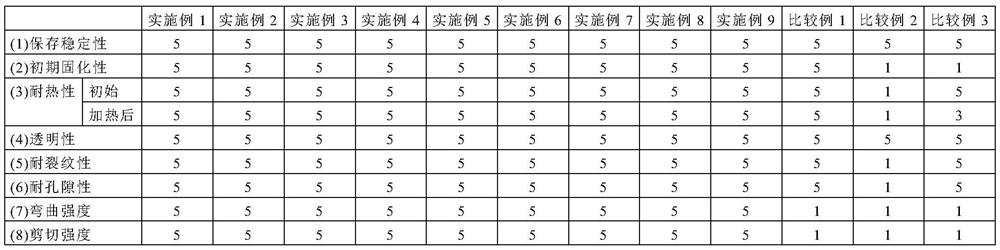

Examples

Embodiment

[0088] Hereinafter, although an Example and a comparative example demonstrate this invention in detail, the scope of this invention is not limited to these. In addition, in each example, unless otherwise indicated, a part is based on mass.

[0089] In the production example, the weight-average molecular weight was obtained based on gel permeation chromatography (device used: HLC-8220 manufactured by Tosoh Corporation, column: TSKgelα-M manufactured by Tosoh Corporation, developing solvent: tetrahydrofuran) The conversion value of the polystyrene standard substance.

[0090] In the manufacturing example, 1 The displacement value of H-NMR is obtained by using VARIAN 400-MR (400MHz, CDCl 3 ) to obtain the measured value.

[0091] In Examples, the viscosity is a measured value obtained by using an E-type viscometer (product name "RE-80U", manufactured by Toki Sangyo Co., Ltd., rotor number 1°34'×R24, rotor speed 5 rpm).

[0092]

manufacture example 1

[0094] 136.2 parts of methyltrimethoxysilane and 10.8 parts of water were added to a reaction device equipped with a stirrer, a condenser, a thermometer and a nitrogen gas introduction pipe, and the temperature of the reaction system was raised to 40°C. Next, 0.14 parts of formic acid was added to initiate the hydrolysis reaction. After the start of the reaction, the temperature of the reaction system reached 62° C. due to the heat of reaction, but thereafter the temperature was lowered to 40° C., and this temperature was maintained for 30 minutes. Thereafter, the temperature of the reaction system was raised to 120° C. over 3 hours while removing accompanying methanol from the system. Next, by carrying out a condensation reaction at this temperature for 1 hour, the 3 SiO 3 / 2 The liquid polysilsesquioxane (B-1) of the silsesquioxane group unit (x=1, y=0) shown. (B-1) The viscosity of the component was 20 mPa·s / 25 degreeC, and the weight average molecular weight was 900. In...

manufacture example 2

[0096] The input amount of water is set as 16.2 parts, except that, operate in the same manner as in Production Example 1, obtain 3 SiO 3 / 2 A liquid polysilsesquioxane (B-2) having a silsesquioxane group unit (x=1, y=0) represented. The component (B-2) had a viscosity of 350 mPa·s / 25° C., a weight average molecular weight of 2500, a residual methoxy group content of about 24% by weight, and no residual hydroxyl group peak was observed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com