Microemulsion and its preparation method and application and treatment method of oily drilling cuttings

A technology of microemulsion and degreasing agent, which is applied in the field of petroleum engineering drilling, can solve the problems of high transportation costs, impact, and high requirements for incineration equipment, and achieve the effect of saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

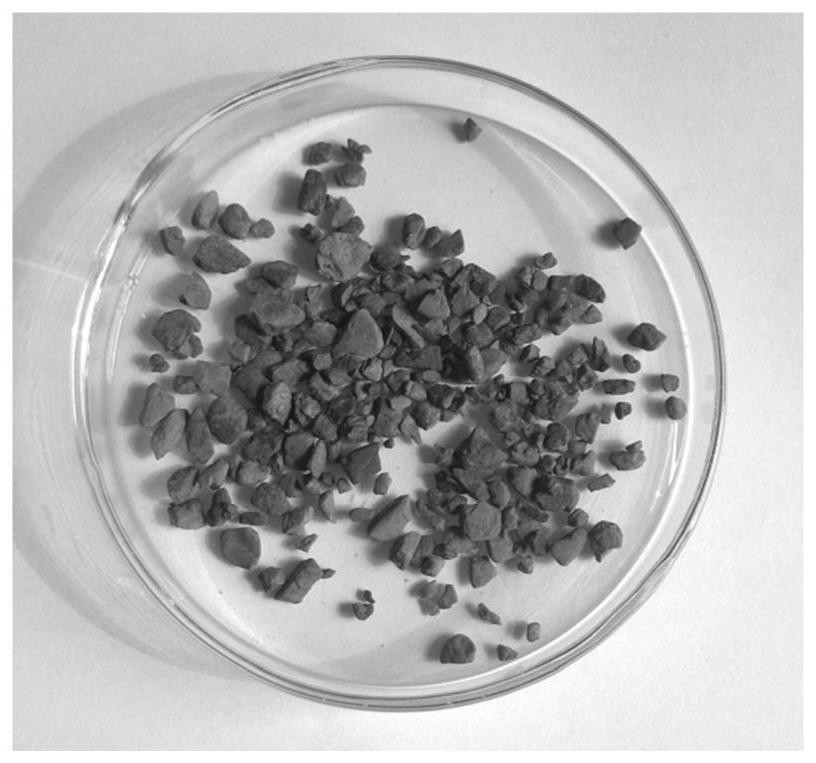

Image

Examples

preparation example Construction

[0027] According to the second aspect of the present invention, the present invention provides the preparation method of described microemulsion, this method comprises:

[0028] 1) Sodium chloride is dissolved in water to obtain an aqueous sodium chloride solution;

[0029] 2) mixing the ionic surfactant, co-surfactant, and oil phase to obtain a mixed solution;

[0030] 3) mixing the aqueous sodium chloride solution with the mixed solution to obtain the microemulsion.

[0031] The mixing of step 2) and step 3) can be carried out under stirring conditions, and the stirring equipment can be a magnetic stirrer.

[0032] In order to further promote the uniform mixing of the ionic surfactant, the co-surfactant and the oil phase, preferably, step 2) includes: first stirring the ionic surfactant and the co-surfactant, and then adding the The oil phase was continuously stirred until uniform.

[0033] In order to further avoid delamination of the microemulsion, preferably, step 3) i...

Embodiment 1

[0042] This example is used to illustrate the microemulsion of the present invention and its preparation method.

[0043] (1) configuration concentration is the sodium chloride aqueous solution of 2.5% by weight;

[0044] (2) Stir 5g fatty alcohol polyoxyethylene ether sodium sulfate and 3g butyl propionate evenly with a magnetic stirrer, then add 2g 5# white oil and continue stirring until uniform to obtain a mixed solution;

[0045] (3) Take 20 g of sodium chloride aqueous solution and 10 g of the mixed solution, stir with a magnetic stirrer until completely clear, and continue stirring for 1 h to obtain a microemulsion.

Embodiment 2

[0047] This example is used to illustrate the microemulsion of the present invention and its preparation method.

[0048] (1) configuration concentration is an aqueous sodium chloride solution of 3.0% by weight;

[0049] (2) Stir 8g fatty alcohol polyoxyethylene ether sodium sulfate and 6g amyl propionate evenly with a magnetic stirrer, then add 4g tetradecene and continue stirring until uniform to obtain a mixed solution;

[0050] (3) Take 25 g of sodium chloride aqueous solution and 13 g of the mixed solution, stir with a magnetic stirrer until completely clear, and continue stirring for 1 h to obtain a microemulsion.

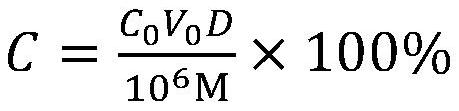

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com