Microencapsulated photochromic powder resistant to weather for long time and preparation method thereof

A microencapsulation and photochromic technology, applied in microcapsule preparation, microsphere preparation, dyeing method, etc., can solve the problems of poor weather resistance and acid resistance of single-layer microencapsulated photochromic powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

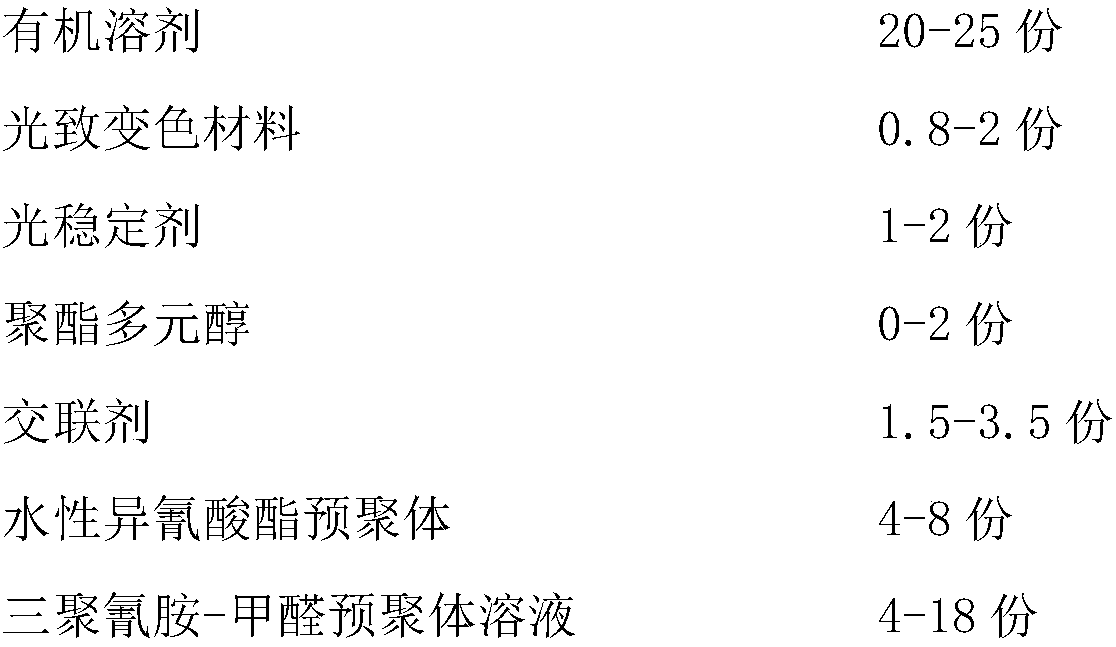

[0109] Long weather resistance microencapsulated photochromic powder, including the following components:

[0110]

[0111] MOCA: English name 3,3,-dichloro-4,4,-diamino-diphenylmethane.

[0112] The photochromic compound dye is spirooxazine (Nankai University Fine Chemical Experimental Factory, melting point 145° C., decomposition temperature 260° C.).

[0113] The preparation method of the long weather-resistant microencapsulated photochromic powder is:

[0114] 1) Preparation of core material: Add photochromic material, light stabilizer, and crosslinking agent to the organic solvent according to the weight ratio, heat to 140°C, stir to dissolve, cool down to below 20°C, add water-based isocyanate prepolymer into the cooling material, fully stirred evenly to obtain a core material solution.

[0115] 2) Emulsification: add the core material solution to an appropriate amount of 3% neutral emulsifier solution, emulsify at a low speed for a certain period of time, and contr...

Embodiment 2

[0123] Long weather resistance microencapsulated photochromic powder, including the following components:

[0124]

[0125] The photochromic compound is selected from quinolino-spirooxazine photochromic compounds.

[0126] The above-mentioned preparation method of long weather-resistant microencapsulated photochromic powder comprises the following steps:

[0127] 1) Core material preparation: add photochromic material, light stabilizer, polyester polyol, and crosslinking agent to the organic solvent according to the weight ratio, heat to 120°C, stir to dissolve, cool down to below 20°C, and water-based The isocyanate prepolymer is added into the cooling material, and fully stirred evenly to obtain a core material solution.

[0128] 2) Emulsification: add the core material solution to an appropriate amount of 3% neutral emulsifier solution, emulsify at a low speed for a certain period of time, and control the emulsification temperature at 20-25°C to obtain an O / W emulsion w...

Embodiment 3

[0136] The long weather-resistant microencapsulated photochromic powder of the present embodiment 3 comprises the following components:

[0137]

[0138] The photochromic compound is selected from aryl-substituted naphthopyran photochromic compound.

[0139] The above-mentioned preparation method of long weather-resistant microencapsulated photochromic powder comprises the following steps:

[0140] 1) Core material preparation: add photochromic material, light stabilizer, polyester polyol, and crosslinking agent to the organic solvent according to the weight ratio, heat to 130°C, stir to dissolve, cool down to below 20°C, and water-based The isocyanate prepolymer is added into the cooling material, and fully stirred evenly to obtain a core material solution.

[0141] 2) Emulsification: add the core material solution to an appropriate amount of 3% neutral emulsifier solution, emulsify at a low speed for a certain period of time, and control the emulsification temperature at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Solution temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com