Polydopamine modified molybdenum disulfide composite silver nanoparticle antibacterial agent and preparation method thereof

A technology of silver nanoparticles and molybdenum disulfide, which is applied in the direction of antibacterial drugs, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of easy agglomeration, surface defects and unfavorable biological functionalization, etc. Achieve the effect of uniform dispersion, uniform size and regular shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

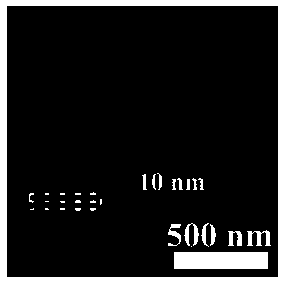

[0037] Mix 0.8mL 10mg / mL silver nitrate solution, 5mL 150μg / mL molybdenum disulfide@polydopamine (MoS 2 @PDA) The nanosheet solution was added to a 50mL jar containing 90μL ammonia solution, and magnetically stirred for 30 min. Then 9.3 mL of 10 mg / mL glucose solution was added, and the magnetic stirring reaction was continued for 1.5 h. Wash with ultrapure water several times, centrifuge at 12,000 rpm, and centrifuge for 40 minutes, and disperse the final product in ultrapure water to obtain polydopamine-modified molybdenum disulfide composite silver nanoparticle antibacterial agent. figure 1 The polydopamine-modified molybdenum disulfide composite silver nanoparticle antibacterial agent has regular shape and uniform dispersion, and the size of the silver nanoparticle is about 5-6nm. from figure 2 It can be seen that the thickness of the prepared polydopamine-modified molybdenum disulfide composite silver nanoparticle antibacterial agent is about 10 nm. Under this conditi...

Embodiment 2

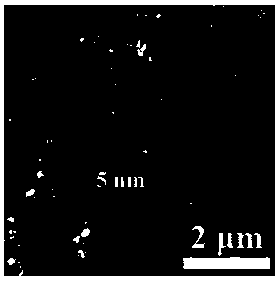

[0039] Mix 0.8mL 10mg / mL silver nitrate solution, 5mL 150μg / mL molybdenum disulfide@polydopamine (MoS 2 @PDA) The nanosheet solution was added to a glass vessel containing 180 μL ammonia solution and stirred magnetically for 20 min. Then 9.3 mL of 10 mg / mL glucose solution was added, and the magnetic stirring reaction was continued for 1 h. Wash with ultrapure water several times, centrifuge at 12,000 rpm, and centrifuge for 20 minutes, and disperse the final product in ultrapure water to obtain polydopamine-modified molybdenum disulfide composite silver nanoparticle antibacterial agent. image 3 The polydopamine-modified molybdenum disulfide composite silver nanoparticle antibacterial agent has regular morphology, dense distribution of silver nanoparticles, and a size of about 5-6nm. Under this condition, the molar ratio of ammonia water to silver nitrate is 100:1, and the molar ratio of silver nitrate to molybdenum disulfide is 10:1.

Embodiment 3

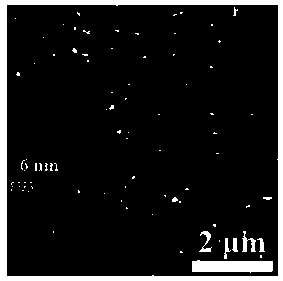

[0041] Mix 0.8mL of 10mg / mL silver nitrate solution, 5mL of 150μg / mL molybdenum disulfide@polydopamine (MoS 2@PDA) The nanosheet solution was added to a glass vessel containing 180 μL of ammonia solution and stirred magnetically for 20 min. Then add 9.3mL of 10mg / mL glucose solution, and react in microwave at 60°C for 10min. Washing with ultrapure water several times, the centrifugation speed is 12000rpm, and the centrifugation time is 20min, and the final product is dispersed in ultrapure water to obtain polydopamine-modified molybdenum disulfide composite silver nanoparticle antibacterial agent. Figure 4 The polydopamine-modified molybdenum disulfide composite silver nanoparticle antibacterial agent has regular morphology, dense distribution of silver nanoparticles, and a size of about 5-6nm. Under this condition, the molar ratio of ammonia water to silver nitrate is 100:1, and the molar ratio of silver nitrate to molybdenum disulfide is 10:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com